Method for improving matching voltage difference of lithium batteries

A lithium battery and grouping technology, which is applied to secondary batteries, secondary battery repair/maintenance, secondary battery charging/discharging, etc., can solve problems such as lithium battery pack pressure difference alarms, and achieve the effect of improving performance and experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

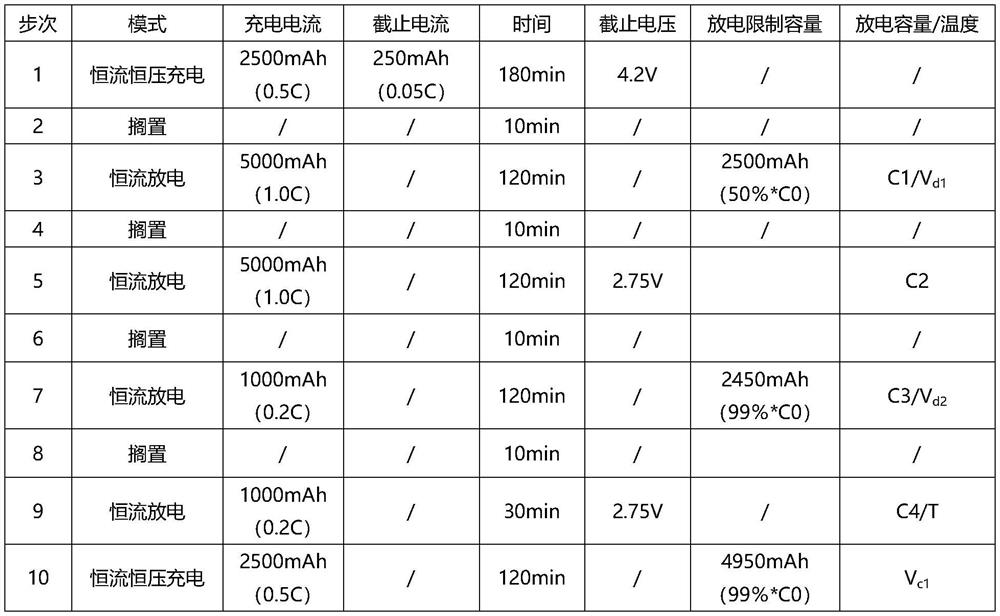

Embodiment 1

[0052] A 26650 lithium battery with a designed capacity of 5000mAh. The lithium battery includes a positive electrode nickel cobalt lithium manganate ternary material, a negative electrode graphite, a lithium hexafluorophosphorus electrolyte, a diaphragm, a steel shell and other key materials. The basic principle is that the positive electrode is charged during charging. The method for improving the lithium battery matching pressure difference includes the following steps:

[0053] 1), take 8pcs lithium battery and put it on hold in a constant temperature environment of 25℃ for 30min, then charge it to 4.2V with 0.5C constant current and constant voltage according to the requirements of the product specification, and the cut-off current is 0.05C;

[0054] 2) Discharge to 2.75V according to the standard discharge current 0.2C specified in the product specification after 10min, and the discharge capacity is marked as C(0);

[0055] 3), according to step 1), recharge the lithium ...

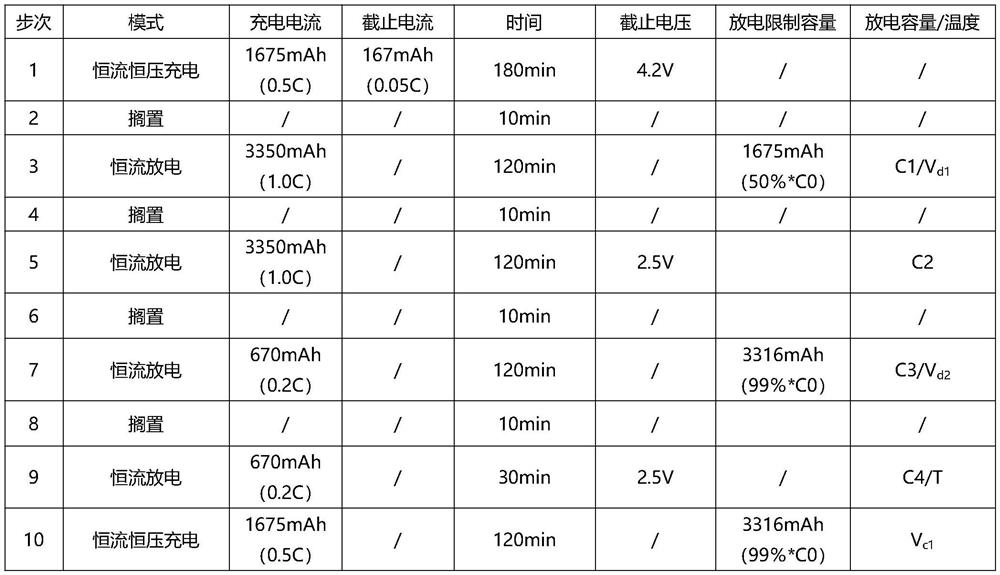

Embodiment 2

[0063] A 18650 lithium battery with a designed capacity of 3350mAh, the lithium battery includes key materials such as positive electrode nickel cobalt aluminum material, negative electrode graphite, lithium hexafluorophosphorus electrolyte, diaphragm, steel shell, etc. During discharge, the negative electrode graphite deintercalates lithium ions and returns to the positive electrode material.

[0064] The method for improving the pressure difference of lithium battery matching group includes the following steps:

[0065] 1), take 8pcs lithium battery and put it on hold in a constant temperature environment of 25℃ for 30min, then charge it to 4.2V with 0.5C constant current and constant voltage according to the requirements of the product specification, and the cut-off current is 0.05C;

[0066] 2) Discharge to 2.5V according to the standard discharge current 0.2C specified in the product specification after 10 minutes of storage, and the discharge capacity is marked as C(0); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com