Skull drilling impedance feedback system and control method

A feedback system and feedback control technology, used in bone drill guidance, medical science, surgery, etc., can solve the problem that the dynamic measurement process of cranial drilling cannot be applied, it is difficult to integrate craniotomy devices, and it is difficult to span a large measurement range and weak signals. requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

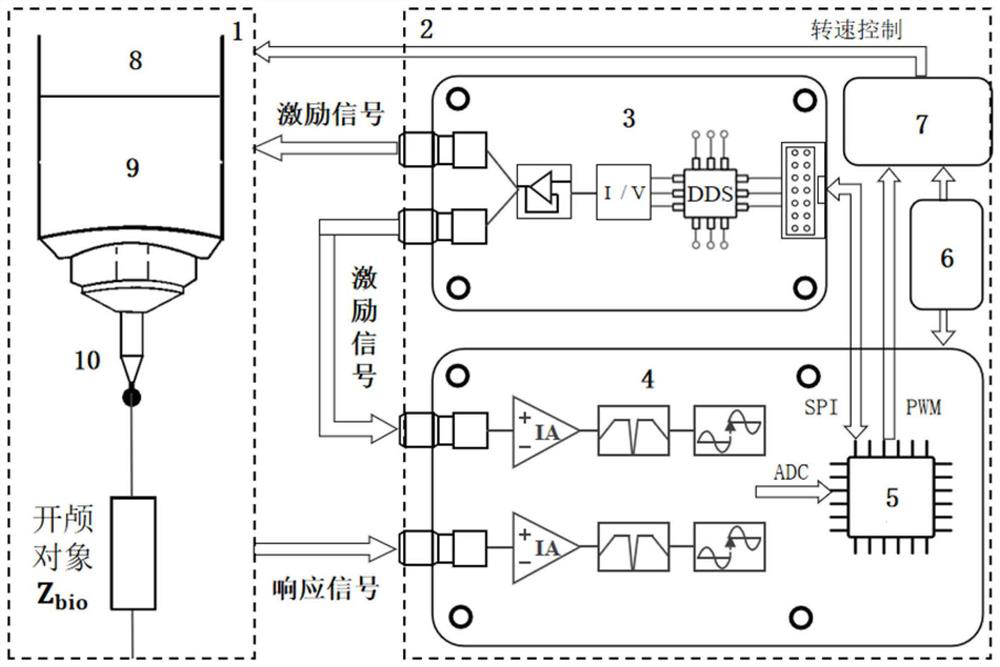

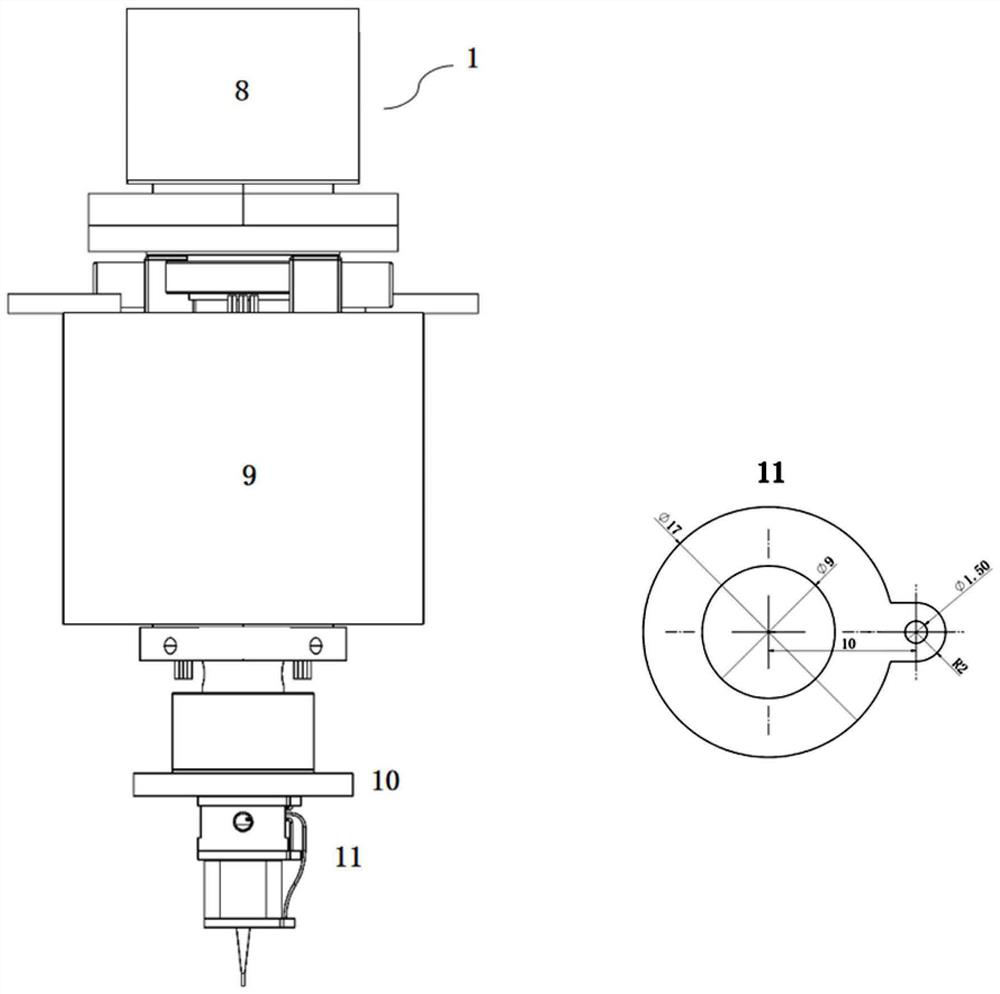

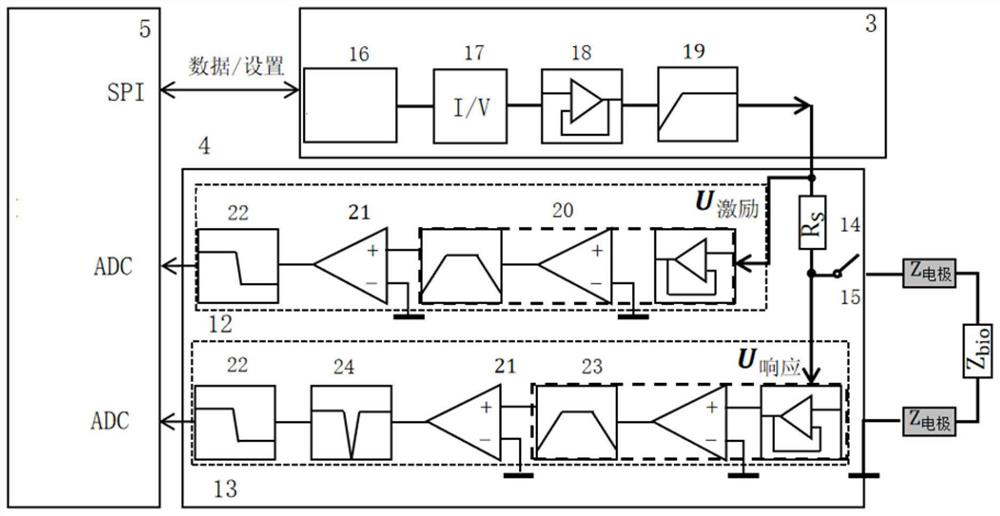

[0026] like figure 1 As shown, the application environment of the electrical impedance feedback system for skull drilling in this embodiment includes: a conductive drilling end 1 and an electrical impedance measuring mechanism 2, and the electrical impedance measuring mechanism 2 includes: an excitation signal generator 3, an analog signal processing front end 4 , microprocessor 5, power management unit 6, drilling motor drive unit 7; conductive drilling end 1 includes: drilling motor 8, conductive slip ring 9, conductive drill chuck 10, wherein: excitation signal generator 3 generates two The same excitation signal in the same way is output to the fixed end of the conductive slip ring 9 and then conducts to the rotating conductive drill bit to excite the brain tissue to generate a response signal. The other channel is used as a reference signal and a response signal to be input to the analog signal processing front end 4 for synchronous amplification and conditioning. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com