Preparation method and application of MIL-125 loaded 1T-phase molybdenum sulfide composite photocatalyst

A MIL-125, molybdenum sulfide technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve weak photocatalytic performance, poor photoresponse ability, etc. problem, to achieve the effect of improved responsiveness, low cost, and enhanced ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

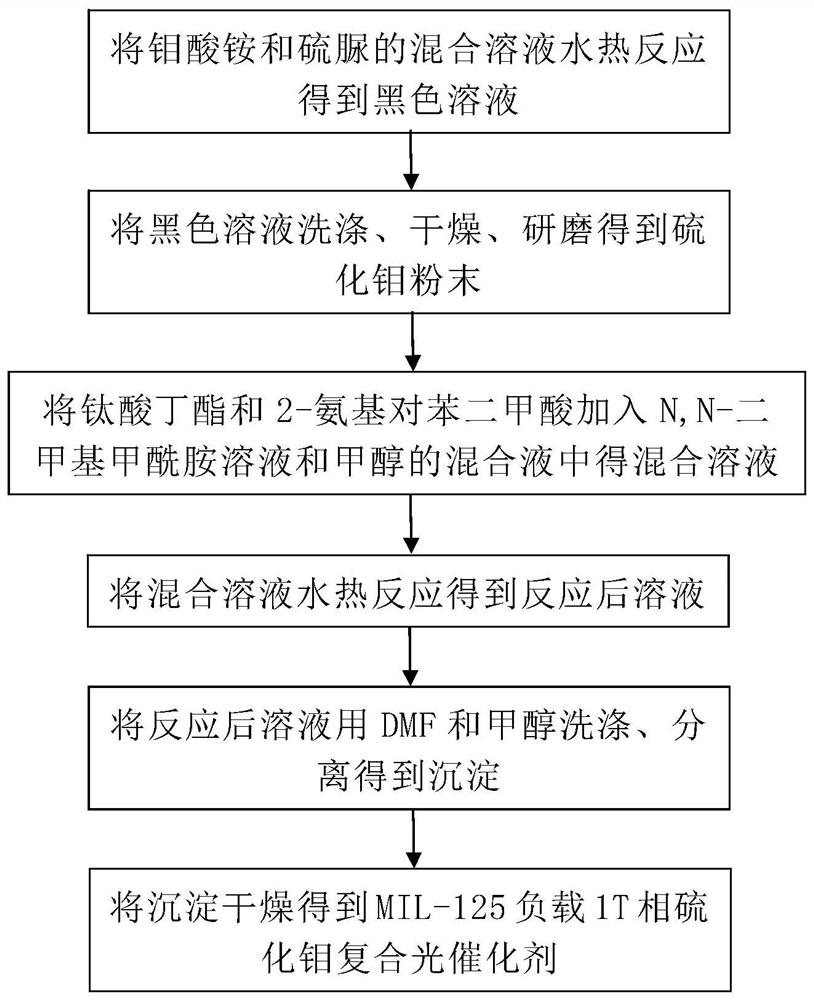

[0029] see figure 1 , a preparation method of a MIL-125 loaded 1T phase molybdenum sulfide composite photocatalyst provided in the embodiment of the present invention comprises the following steps:

[0030] Step 1) Dissolve thiourea and ammonium molybdate in deionized water and fully stir to obtain a mixed solution, then transfer the mixed solution to a reaction kettle and put it into an oven, and perform a hydrothermal reaction to obtain a black solution.

[0031] Wherein, the molar ratio of ammonium molybdate mixed with thiourea is 1:2-1:3, and the stirring temperature of thiourea and ammonium molybdate in deionized water is 15-25°C. The hydrothermal temperature for the hydrothermal reaction of the mixed solution of thiourea and ammonium molybdate is 170-230°C, and the holding time is 18-30h.

[0032] Step 2) Wash the obtained black solution with absolute ethanol to remove impurities, then transfer to a constant temperature oven for drying, and grind the solid obtained by d...

Embodiment 1

[0049] Add thiourea and ammonium molybdate into deionized water, stir and mix thoroughly, transfer the mixed solution to the reaction kettle, set the temperature of the reaction kettle to 200°C, and carry out hydrothermal reaction, and the reaction lasts for 24 hours. Then the reaction kettle was taken out and cooled naturally, and the obtained solution was suction filtered with 200 ml of absolute ethanol. After suction filtration, it was transferred to a constant temperature drying oven at 60°C for drying for 10 hours, and the samples were ground to obtain black 1T phase molybdenum sulfide powder.

Embodiment 2

[0051] 25 ml of DMF and 25 ml of methanol were mixed, and 1.09 g of 2-aminoterephthalic acid and 1.02 g of butyl titanate were added thereto and mixed well. The mixture was transferred to a reactor for hydrothermal reaction, the reaction temperature was 150° C., the reaction continued for 16 hours, and the reaction was naturally cooled after the completion of the reaction. The obtained yellow solution was centrifuged at a high speed at 7000 r / min, the precipitate was taken out after five minutes, and 50 ml of DMF was added for washing for two hours. After washing, centrifuge again to obtain a precipitate, and perform the second DMF washing. The precipitate was obtained by centrifugation again, and 50 ml of methanol was added for washing for two hours. After washing, centrifuge again to obtain a precipitate, which is then washed with methanol for the second time. After the last washing, the precipitate obtained by centrifugation was placed in a constant temperature drying ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com