Artificial particle board adhesive and production method thereof

A production method and technology of artificial particles, applied in adhesive types, aldehyde/ketone condensation polymer adhesives, adhesives, etc., can solve the problem of reduced service life of artificial particle boards, difficult discharge of urea-formaldehyde glue, and easy erosion by moths and other problems, to achieve the effect of increasing anti-moth ability, strong cleaning ability, and reducing cost and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An artificial particle board adhesive and a production method thereof, according to the weight parts ratio of 600-700 parts of formaldehyde, 35-45 parts of melamine, 6-14 parts of camphor oil, 200-220 parts of urea, 600 parts by weight Preparation of ~650 caustic soda solution, 200-300 ammonium chloride solution, 3-7 parts of sodium cellulose, 3-7 parts of ammonia water and 3-7 parts of polyvinyl alcohol;

[0036] The production method consists of the following steps:

[0037] S1, the formaldehyde of 600~700 parts is added in stirring tank 5, add the polyvinyl alcohol that is weighed, control heating mechanism 6 heating by electric control box 9, when the formaldehyde temperature in stirring tank 5 reaches 25 ℃~35 ℃, Adjust the pH of the formaldehyde to 7.4-7.9 with 200-210% of caustic soda solution, and then add 3-7 parts of sodium cellulose;

[0038] S2, continue to be heated to when the formaldehyde temperature in stirring tank 5 reaches 36 ℃~40 ℃, be 120~130 parts ...

Embodiment 2

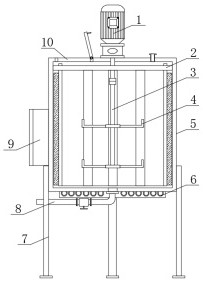

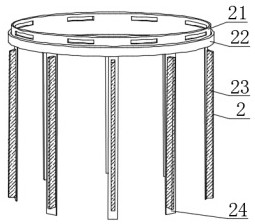

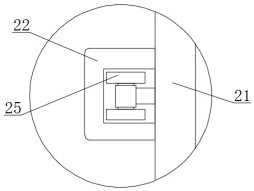

[0044] like Figure 1-3 As shown, a kind of equipment for the production method of artificial particle board adhesive, the stirring tank 5 includes a gear motor 1, an auxiliary scraping device 2, a transmission shaft 3, a stirring blade 4, a heating mechanism 6, a support frame 7, and a discharge pipe 8 , the electric control box 9 and the feeding port 10, the middle of the upper end of the stirring tank 5 is fixed with a geared motor 1, and the lower end of the geared motor 1 is located inside the stirring tank 5 and is connected with a transmission shaft 3 through a rotating shaft, and the lower end of the transmission shaft 3 is fixed with a The stirring blade 4, the lower left of the geared motor 1, is located at the upper left side of the stirring tank 5, and is provided with a feeding port 10. The lower side of the left end of the stirring tank 5 is fixed with an electric control box 9, and the outer side of the lower end of the stirring tank 5 is fixed with a support fra...

Embodiment 3

[0047] like Figure 1-3 As shown, a kind of equipment for the production method of artificial particle board adhesive, the stirring tank 5 includes a gear motor 1, an auxiliary scraping device 2, a transmission shaft 3, a stirring blade 4, a heating mechanism 6, a support frame 7, and a discharge pipe 8 , the electric control box 9 and the feeding port 10, the middle of the upper end of the stirring tank 5 is fixed with a geared motor 1, and the lower end of the geared motor 1 is located inside the stirring tank 5 and is connected with a transmission shaft 3 through a rotating shaft, and the lower end of the transmission shaft 3 is fixed with a The stirring blade 4, the lower left of the geared motor 1, is located at the upper left side of the stirring tank 5, and is provided with a feeding port 10. The lower side of the left end of the stirring tank 5 is fixed with an electric control box 9, and the outer side of the lower end of the stirring tank 5 is fixed with a support fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com