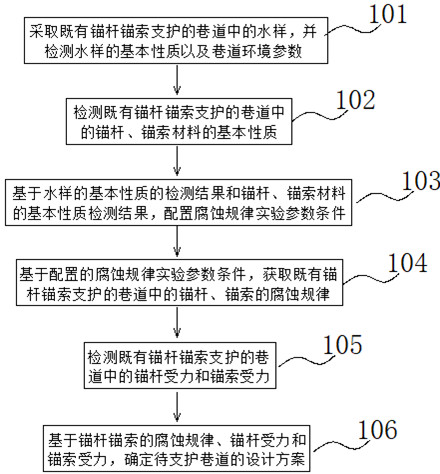

Roadway anchor rod and anchor cable support design method in corrosive mine environment

A technology of anchor cable support and design method, which is applied in mining equipment, design optimization/simulation, tunnels, etc. It can solve the problems of deteriorating the working state of bolts, aggravating corrosion, damage and fracture of rods, etc., so as to ensure long-term stability and reduce corrosion Probability of failure, effect of improving reliability and long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

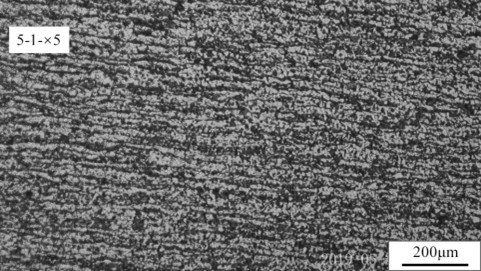

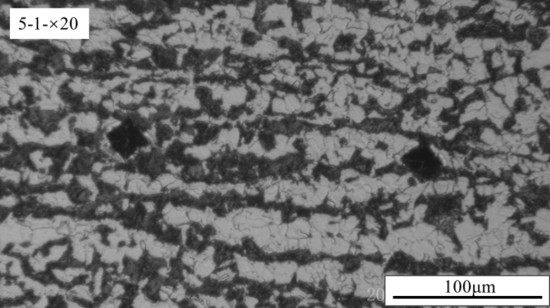

Embodiment 1

[0091] Take a mine in the northwest as an example to further illustrate the technical solution of the present invention:

[0092] The roadway numbered F (mining roadway, serviced for 3 years) in a mine in the northwest that is supported by existing bolts and cables, the roof is exposed to water during the entire service process, the ambient humidity is high, and the roadway is supported by bolts, cables and Pallet, metal mesh and other components have obvious corrosion phenomenon. In the roadway of the coal pillar retaining roadway, under the influence of strong mining, part of the bolts and bolts in the roadway are broken, and the roadway is greatly deformed. Carry out bolt bolt and cable support design for the roadway to be constructed with similar environment to roadway F;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com