Preparation method of lithium battery positive plate, positive plate and lithium ion battery

A positive electrode sheet and lithium battery technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of fracture and brittle cracks of the positive electrode sheet, and achieve the goal of improving flexibility and solving the problem of brittle fracture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

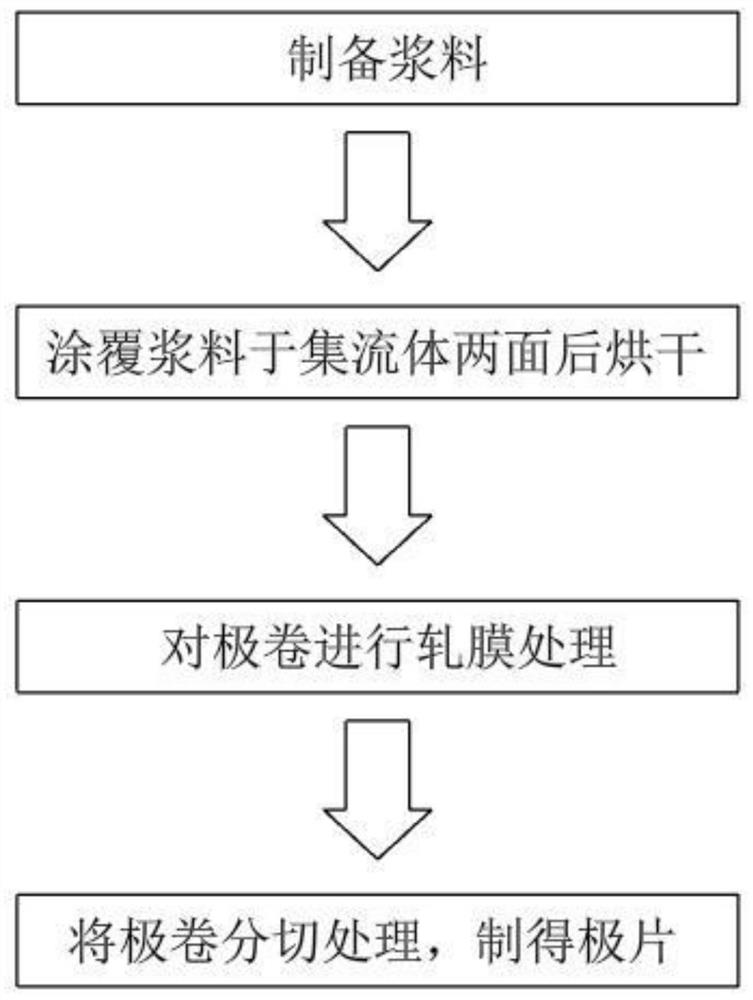

[0032] Based on the above ideas, one of the objectives of the present invention is to provide a method for preparing a positive electrode sheet for a lithium battery, comprising the following steps:

[0033] (1) Mix the active material with the conductive agent, the binder and the solvent according to a certain proportion, and make a slurry after stirring;

[0034] (2) drying the slurry evenly on the surface of the current collector, and then winding to obtain a pole roll;

[0035] (3) Roll film processing on the pole roll;

[0036] (4) slitting and slicing the pole roll to obtain a positive electrode sheet;

[0037] The relative humidity of one or more of the steps (2) to (4) is 25% to 100%.

[0038] By controlling the relative humidity of the environment in one or more steps of (2) to (4) from 25% to 100%, the aqueous binder in the positive electrode sheet absorbs moisture in the air, so that the polymer segment of the aqueous binder can be obtained. Fully stretch, improv...

Embodiment 1

[0050] A method for preparing a positive electrode sheet for a lithium battery, comprising the following steps:

[0051] (1) Mix the active material with the conductive agent, the binder and the solvent according to a certain proportion, and make a slurry after stirring;

[0052] (2) drying the slurry evenly on the surface of the current collector, and then winding to obtain a pole roll;

[0053] (3) Roll film processing on the pole roll;

[0054] (4) slitting the pole roll to obtain the positive electrode sheet 1;

[0055] The relative humidity of one or more of the steps (2) to (4) is 25% to 100%.

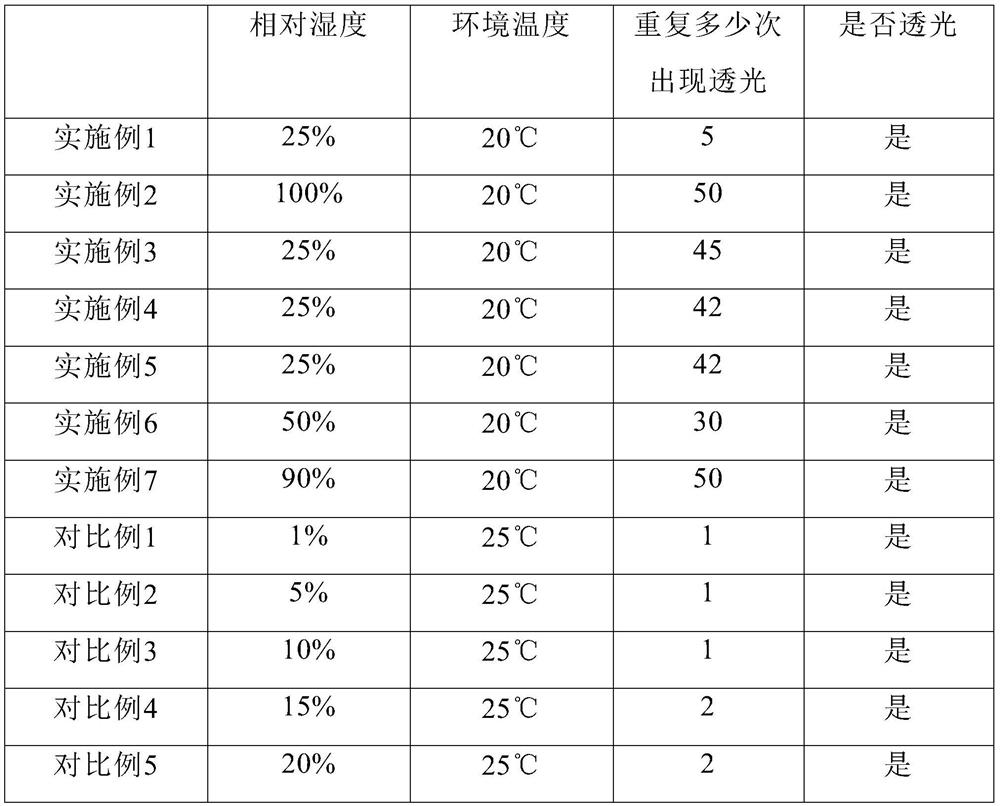

[0056] Flexibility performance (or brittle fracture performance) test: Take a positive electrode sheet 1 with a width of 15mm, 2.30g / ~2.35g / cm3, water content of 1000~1500ppm, and under the environment of relative humidity within 1%, fold the positive electrode sheet 180 degrees in half, and then Roll a 5kg solid steel rod, flatten the positive electrode sheet, observe whether...

Embodiment 2

[0058] The preparation method is the same as in Example 1. The difference is: in step (2), the relative humidity is 100%, and the positive electrode sheet 2 is prepared.

[0059] Flexibility performance (or brittle fracture performance) test: Take positive electrode sheet 2 with a width of 15mm, 2.30g / ~2.35g / cm3, water content of 1000~1500ppm, and under the environment of relative humidity within 1%, fold the positive electrode sheet in half at 180 degrees, and then Roll the 5kg solid steel rod, flatten the positive electrode sheet, observe whether the positive electrode sheet is light-transmitting, fold the positive electrode sheet in half at 180 degrees, and then roll it with a 5kg solid steel rod, flatten the positive electrode sheet, observe whether the positive electrode sheet is light-transmitting, record Repeat the number of times to determine whether the positive electrode sheet begins to crack.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com