Method for manufacturing non-magnetic steel fine powder through water atomization

A non-magnetic steel and manufacturing method technology, applied in the direction of improving process efficiency, etc., can solve the problems of high cost, complex shape and dimensional accuracy of precision casting, and no greater reduction in cost, so as to increase shipments and reduce Production cost and the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for manufacturing a water atomized non-magnetic steel fine powder, comprising the steps of:

[0033] Step 1: Market research, first analyze the market prospect, determine the necessity of market research, analyze the current market demand space, analyze the current production situation, conduct research on the same type of product manufacturers, organize and analyze Research data and write research reports;

[0034] Step 2: According to the research report written by the market research results, design the production scale, including the selection of the address, the establishment of an independent assembly line and the formulation of the production shift system;

[0035] Step 3: Formulate production standards for products;

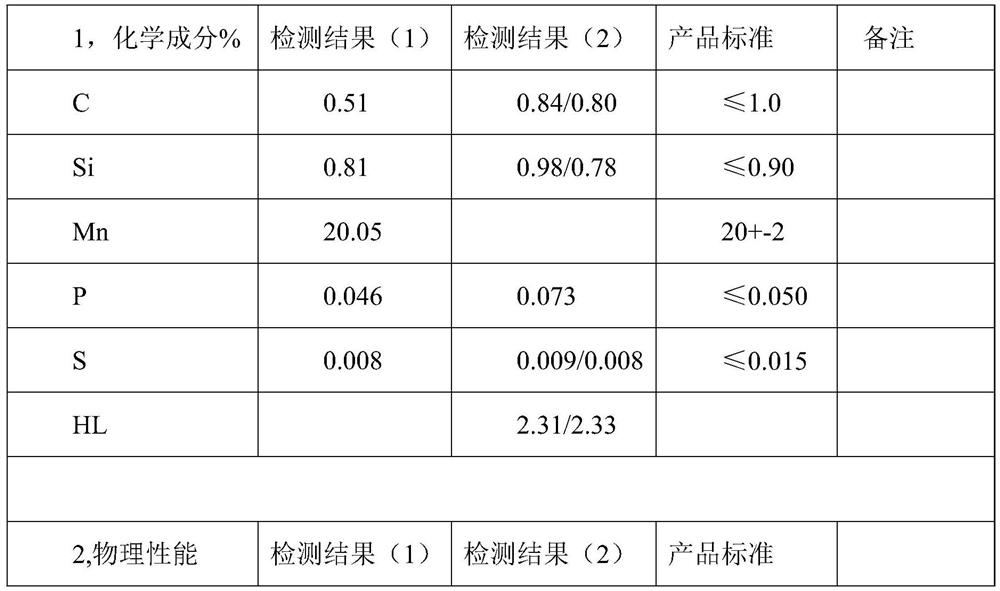

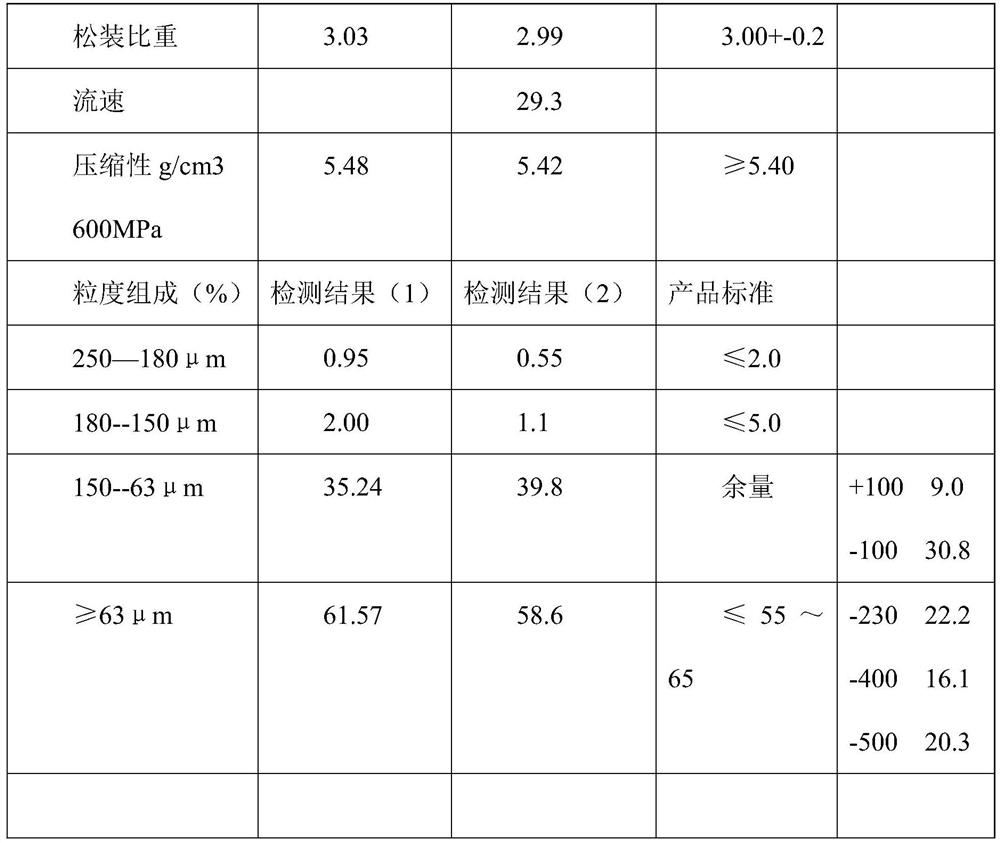

[0036] Table 1 High manganese non-magnetic steel fine powder standards

[0037]

[0038]

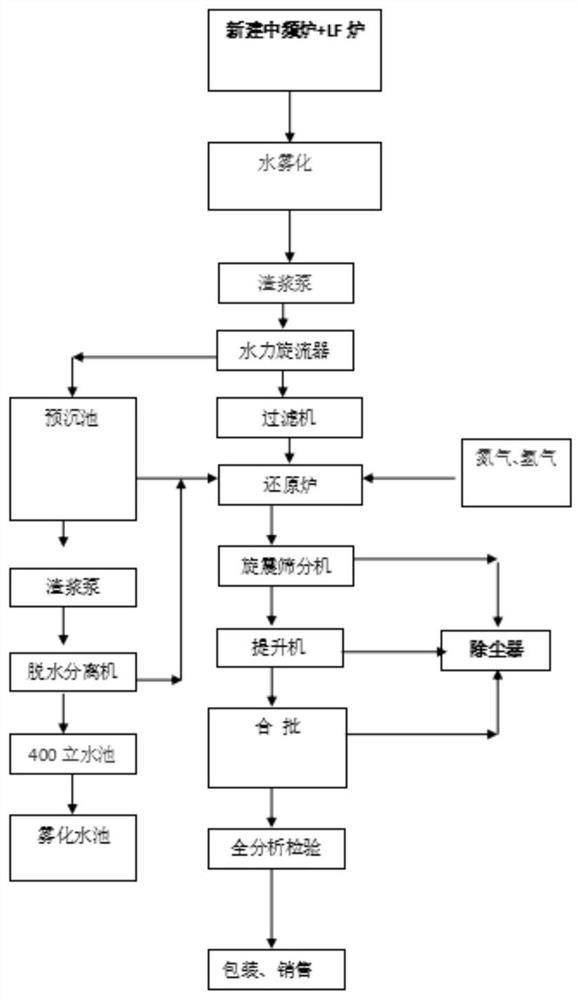

[0039] Step 4: Production process design, including smelting, atomization, dehydration, drying, crushing and screening, and storage and stor...

Embodiment 2

[0048] Example 1

[0049] A method for manufacturing a water atomized non-magnetic steel fine powder, comprising the following steps:

[0050] Step 1: Market research, first analyze the market prospect, determine the necessity of market research, analyze the current market demand space, analyze the current production situation, conduct research on the same type of product manufacturers, organize and analyze Research data and write research reports;

[0051] Step 2: According to the research report written by the market research results, design the production scale, including the selection of the address, the establishment of an independent assembly line and the formulation of the production shift system;

[0052] Step 3: Formulate production standards for products;

[0053] Table 1 High manganese non-magnetic steel fine powder standards

[0054]

[0055] Step 4: Production process design, including smelting, atomization, dehydration, drying, crushing and screening, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com