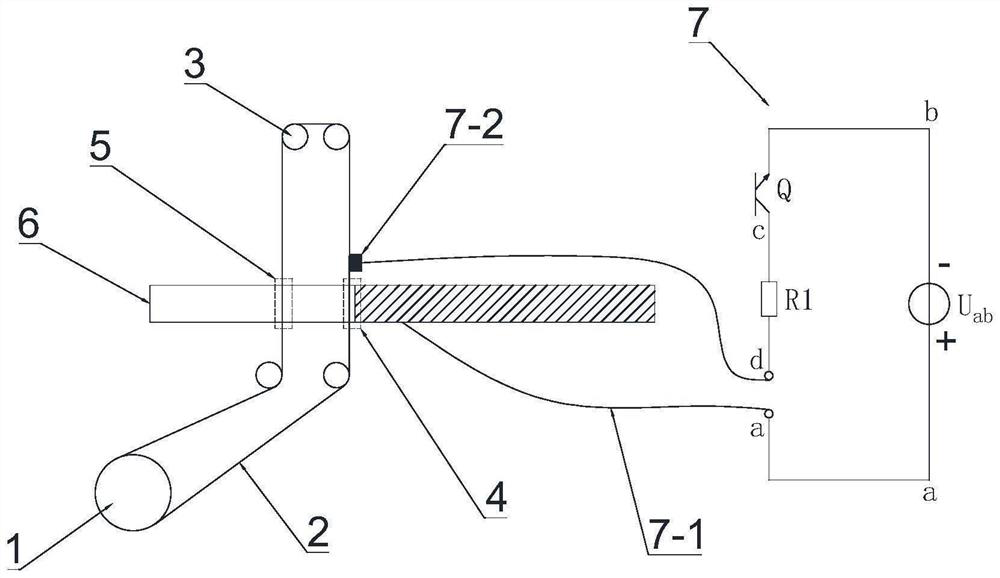

Wire cut electrical discharge machining device and method capable of conducting rough machining and finish machining synchronously

A technology of electric discharge wire and cutting device, which is applied in the direction of accessory devices, metal processing equipment, electric processing equipment, etc., can solve the problems of large processing error, low processing efficiency, and limitation of processing efficiency, so as to reduce processing current and improve The effect of improving processing efficiency and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

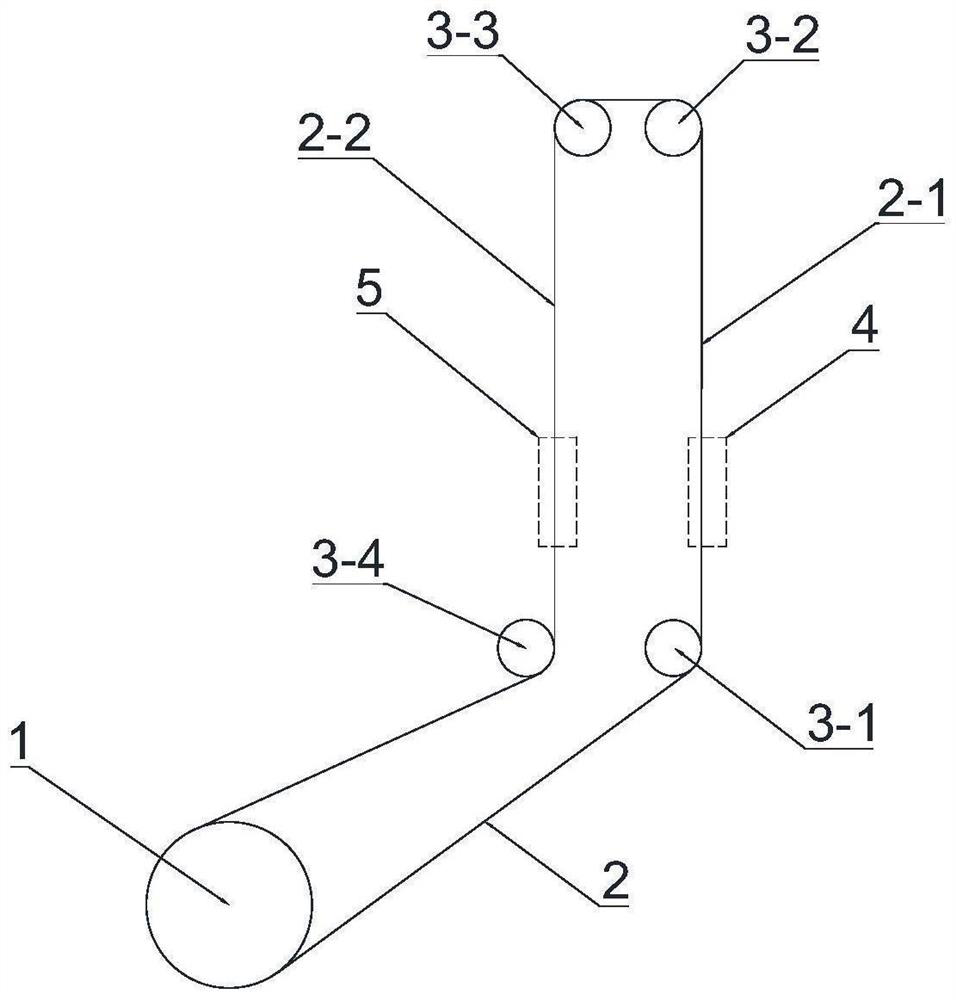

Embodiment 2

[0058] Other specific structures in this embodiment are the same as those in Embodiment 1, the difference is that the number of the electrode wire segments is three segments and other numbers. When the number is three segments, the electrode wire with the largest passing current is Section 2-1 is the rough machining electrode wire section, and the remaining two electrode wire sections with smaller passing current are the finishing wire section 2-2. The smaller the passing current, the higher the machining accuracy; the farther the electrode wire section is from the DC power supply Negative U ab , the smaller the passing current. By adopting the above structure, the processing method of "cutting one and repairing two" can be realized. The second finishing current will also be smaller than the first finishing current. The size of the processing current is the same as the length of the electrode wire 2 (resistance) between the parallel electrode wire segments. value) related.

Embodiment 3

[0060] see Figure 7, the other specific structures in this embodiment are the same as those in Embodiment 1, the difference is that the guide wheel assembly 3 further includes a godet wheel 3-5, the The electrode wire 2 passes through the first threading wheel 3-1, the first capstan 3-2, the godet 3-5, the second capstan 3-3 and the second capstan in sequence. The wire wheel 3-4 is finally rewound to the wire drum 1; by setting the wire godet 3-5, the electrode wire 2 between the parallel electrode wire segments can be ensured to have sufficient length; at the same time, the guide wheel assembly 3 can be become more compact.

Embodiment 4

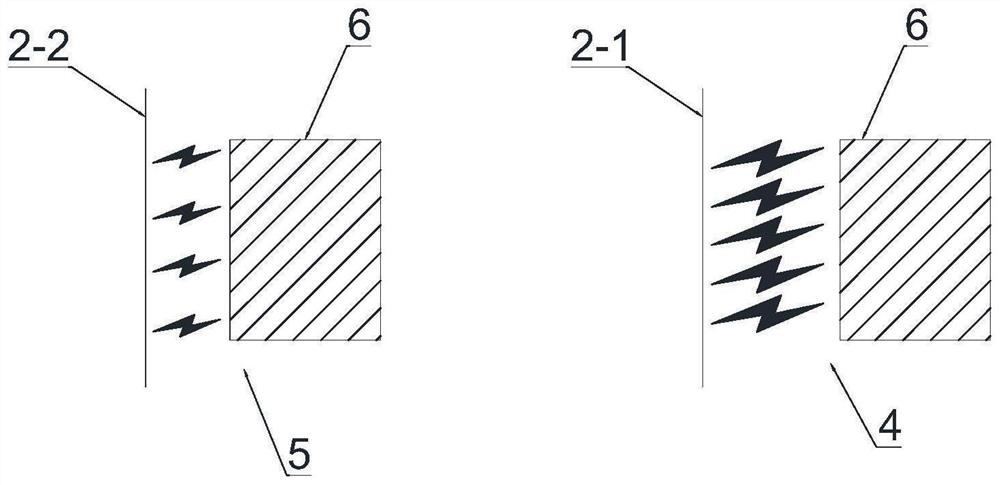

[0062] Other specific structures in this embodiment are the same as those in Embodiment 1, except that a constant value resistor can be connected between the rough machining wire electrode segment 2-1 and the finishing wire electrode wire segment 2-2, thereby changing the The current size of the finishing wire electrode segment 2-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com