Grinding machine with safety protection function

A technology of safety protection and function, which is applied in the direction of grinding machines, grinding/polishing safety devices, manufacturing tools, etc., can solve problems such as grinding disc bursting, safety accidents, and insufficient safety in the cooling process, so as to protect the service life, save resources, and reduce grinding wheels. Dangerous effect of bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

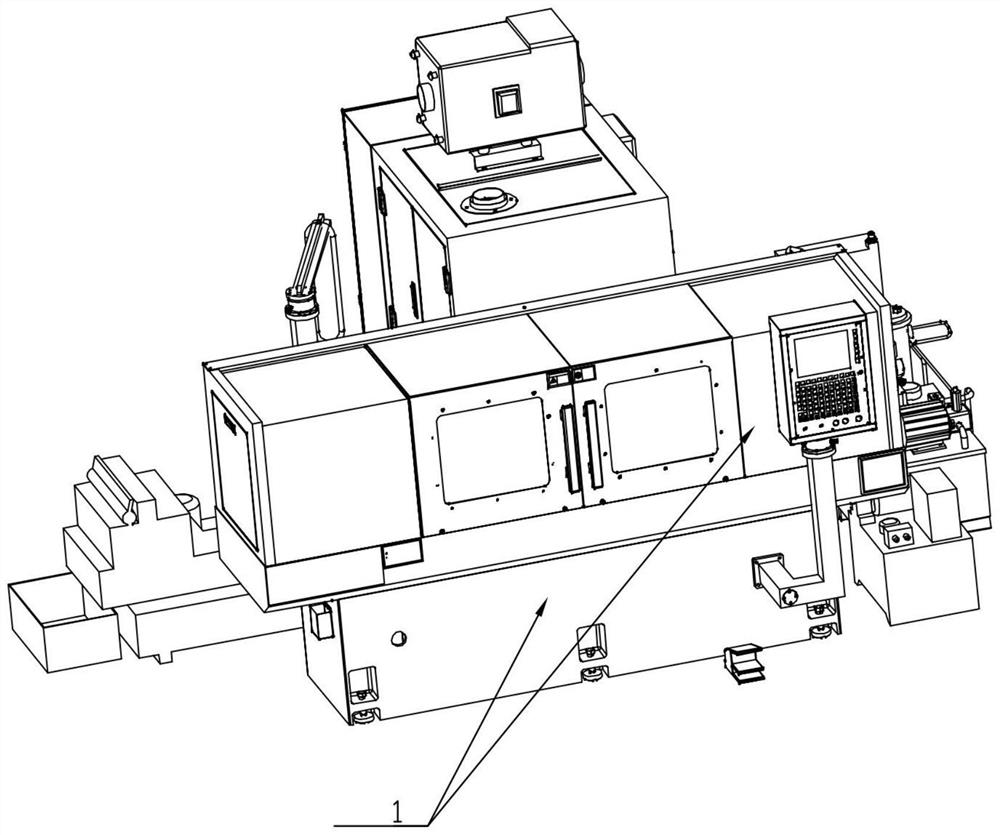

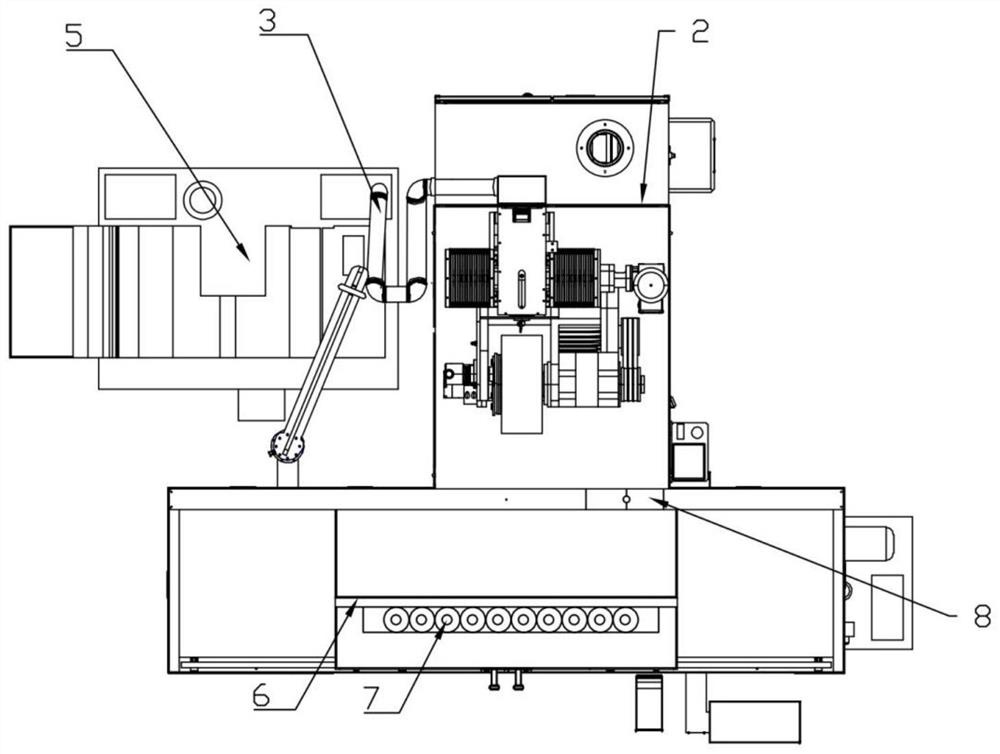

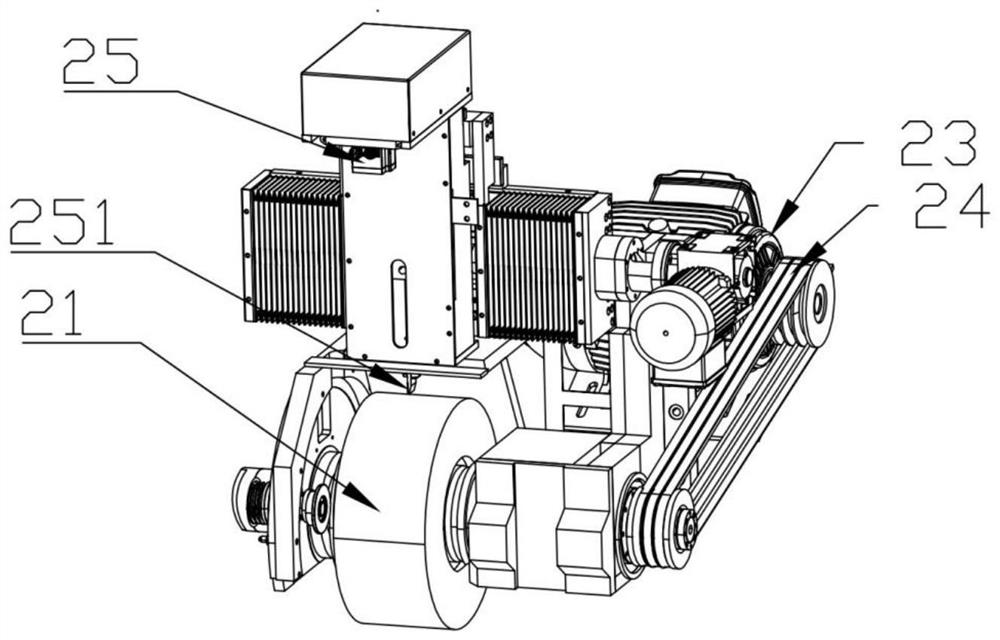

[0025] as attached figure 1 and attached figure 2 As shown, the grinding machine with safety protection function includes a body 1. The body 1 has two upper and lower layers, the upper layer is the work area, the grinding wheel 21 for grinding is installed in the work area, and the lower layer is the support area. The electric wiring of the 12000 is hidden inside the body 1, that is, to prevent safety accidents caused by exposed lines, and the overall appearance is relatively simple, giving people a good feeling experience. The semiconductor cold and hot box is a new type of cooling and heating method that uses the cold end and the hot end of the semiconductor refrigeration sheet to form a thermocouple pair, exchange heat, and can realize direct current cooling or heating. As long as the temperature of the object to be cooled is higher than the cold end face of the semiconductor refrigeration sheet, the heat will be absorbed from the cold end face and transferred to the hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com