Production process of heating decorative gypsum board

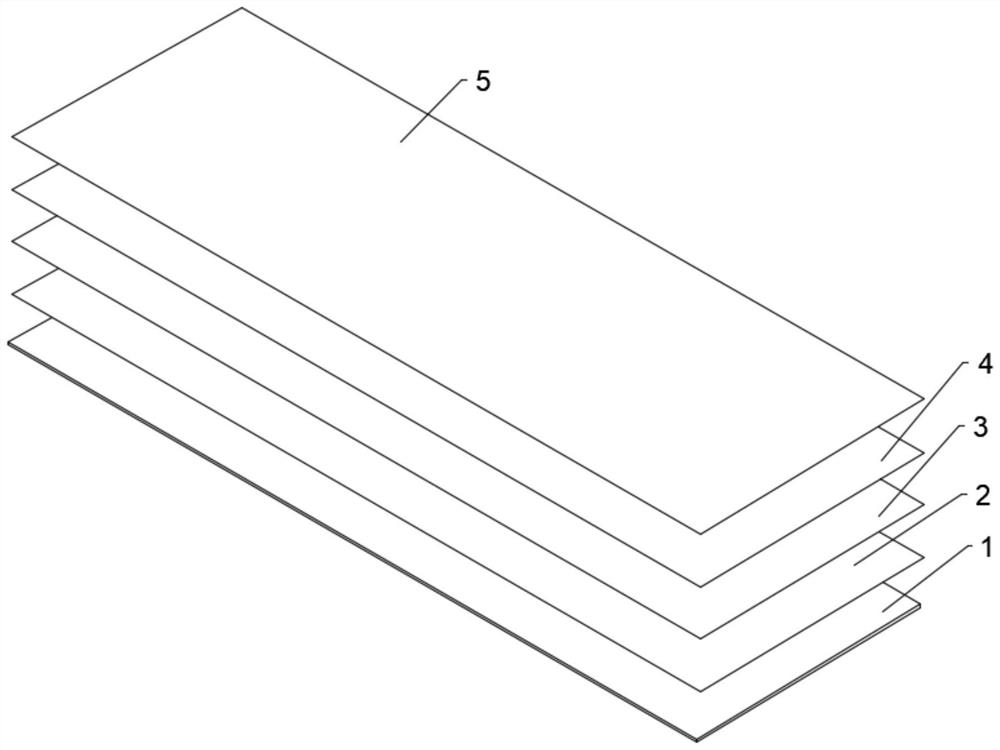

A production process and gypsum board technology, applied in lamination devices, layered products, lamination auxiliary operations, etc., can solve the problems of central heating and high use costs, and achieve the effects of low energy consumption, improved thermal insulation capacity, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Taking cm as the length unit of the paper-faced gypsum substrate, the process of the invention is described in detail:

[0072] 1. Primary sawing treatment

[0073] (1) cutting and sawing the paper gypsum substrate into a plate-like structure with a length of 300 cm, a width of 100 cm and a thickness of 1.2 cm;

[0074] (2) Chamfer the long side of the paper-faced gypsum substrate, and the chamfering angle is 4*45°;

[0075] (3) Punch the peripheral edge of the paper gypsum substrate, the through hole is located at the peripheral edge of the paper gypsum substrate, the diameter of this through hole is 1.6cm, and the center of the nearest through hole is from the nearest paper gypsum substrate. The long side is 3.5cm, and the short side of the nearest gypsum board is 30cm;

[0076] (4) After the drilling is completed, clean the dust and burrs on the surface to obtain a pretreated substrate.

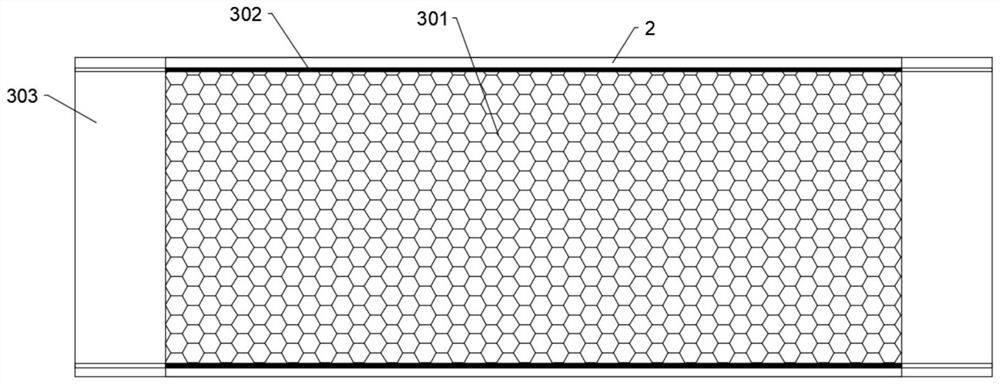

[0077] 2. Lamination of reflective film

[0078] (1) Glue spraying process:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com