Flexible film electrode and preparation method and application thereof

A flexible film and electrode technology, applied in the field of environmental water pollution control and utilization research, can solve the problems of limited practical application, loss of activity, poor stability, etc., and achieve the effect of superior mechanical flexibility, strong stability, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

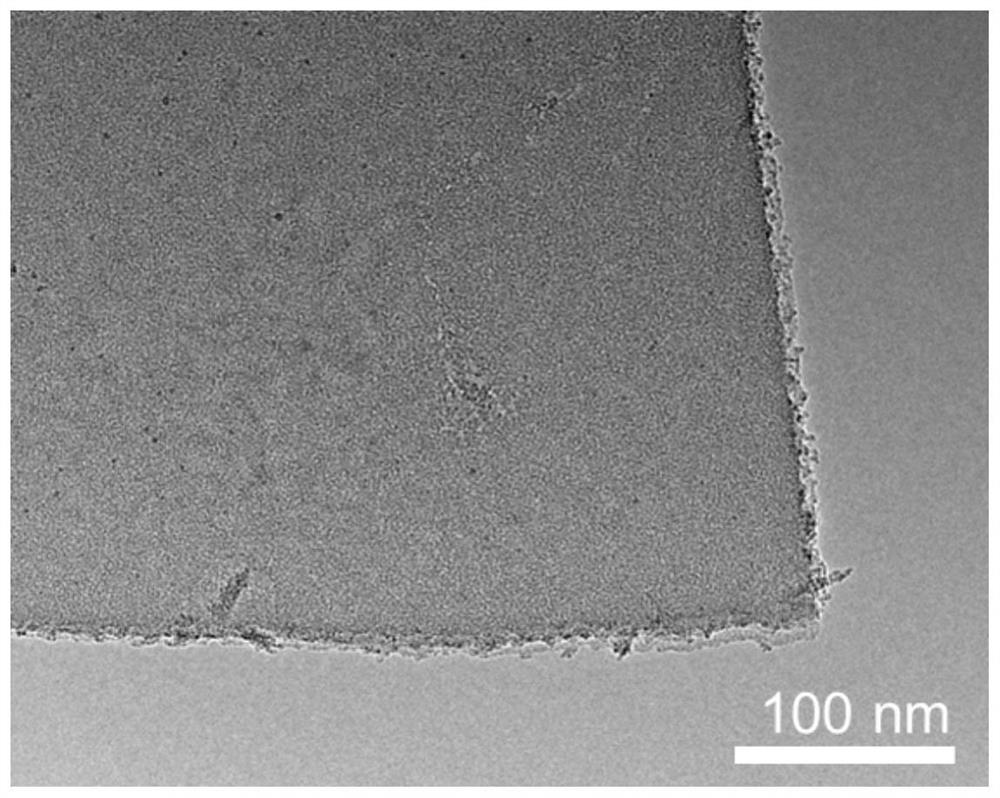

[0042] A two-dimensional flexible CuBDC@Ti 3 C 2 T x Electrode Fabrication Method Seamlessly Coating CuBDC on Electronegative Ti 3 C 2 T x Fabrication of 2D flexible CuBDC@Ti on nanosheets 3 C 2 T x electrode, the specific steps are as follows:

[0043] (1) 1-30g of 1,4-phthalic acid (H 2 BDC) mixed in 100-1000mL of DMF and 50-500mL of CH 3 CN as the bottom layer.

[0044] (2) On this solution, 50-500mL of DMF and 50-500mL of CH 3 CN is added slowly and carefully as an intermediate or spacer layer.

[0045] (3) Finally, in 50-500mL of DMF and 100-1000mL of CH 3 Add 1-10 g of Ti to CN mixture 3 C 2 T x Nanosheets and 3-30g Cu(NO 3 ) 2 ·3H 2 O, slowly add to the tube as the top layer. The solution in the tube was left undisturbed at room temperature for 24 hours to allow the reaction to occur.

Embodiment 1

[0048] 1. Two-dimensional flexible CuBDC@Ti 3 C 2 T x The specific steps for electrode preparation are as follows:

[0049] 10g of 1,4-phthalic acid (H 2 BDC) mixed in 200 mL of DMF and 100 mL of CH 3 CN as the bottom layer.

[0050] On this solution, 100mL of DMF and 100mL of CH 3 CN is added slowly and carefully as an intermediate or spacer layer.

[0051] Finally, in 100mL of DMF and 200mL of CH 3 Add 5 g of Ti to the CN mixture 3 C 2 T x Nanosheets and 10g Cu(NO 3 ) 2 ·3H 2 O, slowly add to the tube as the top layer. The solution in the tube was left undisturbed at room temperature for 24 hours to allow the reaction to occur.

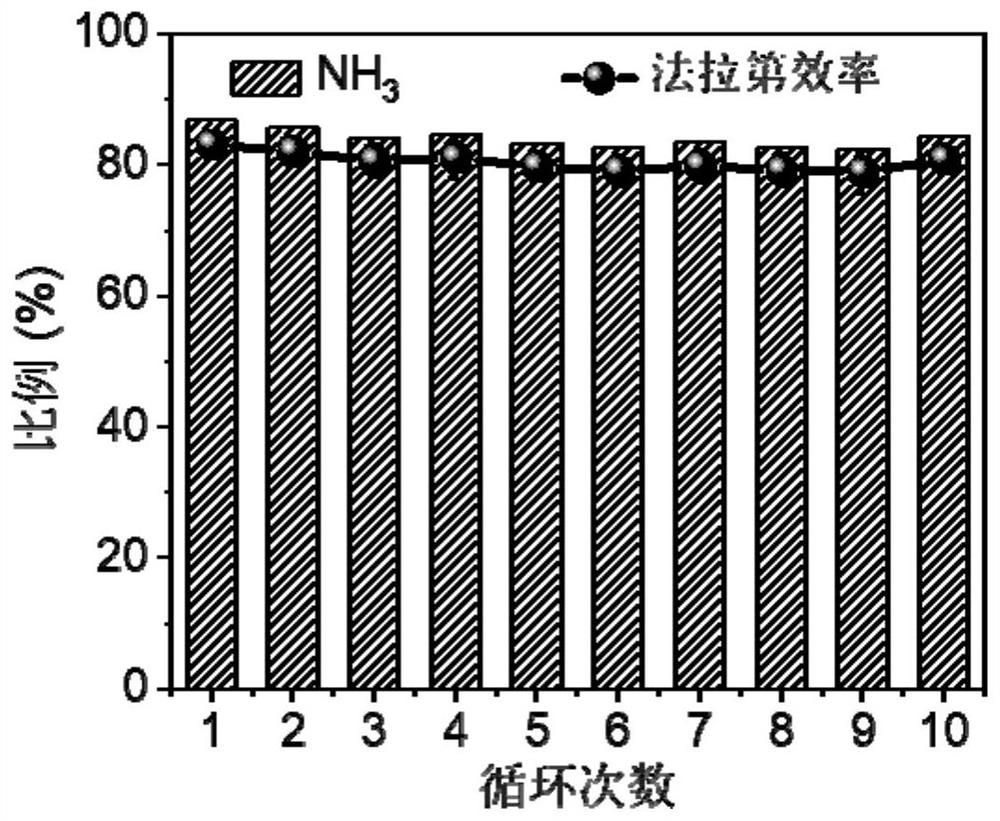

[0052] 2. The obtained 2D flexible CuBDC@Ti 3 C 2 T x Electrodes for ENRA

[0053] 2D Flexible CuBDC@Ti 3 C 2 T x The electrode can be directly used as a working electrode, with platinum electrode as counter electrode and Ag / AgCl electrode as reference electrode to form a three-electrode system; the three-electrode system is pla...

Embodiment 2

[0059] 2D Flexible CuBDC@Ti 3 C 2 T x The preparation of electrodes and the method for catalytic reduction of nitrate are as in Example 1, except that CuBDC@Ti is prepared 3 C 2 T x without adding Ti 3 C 2 T x Nanosheets.

[0060] from Figure 4 It can be seen that the obtained CuBDC electrode still maintains the nanosheet structure with thicker thickness, possibly with partial stacking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com