Modular electrostatic spinning device

An electrospinning and modular technology, applied in textiles and papermaking, filament/thread forming, textile/flexible product manufacturing, etc., can solve the problems of restricted application fields, low production efficiency, application restrictions, etc., and achieve improved Product added value, improved production efficiency, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

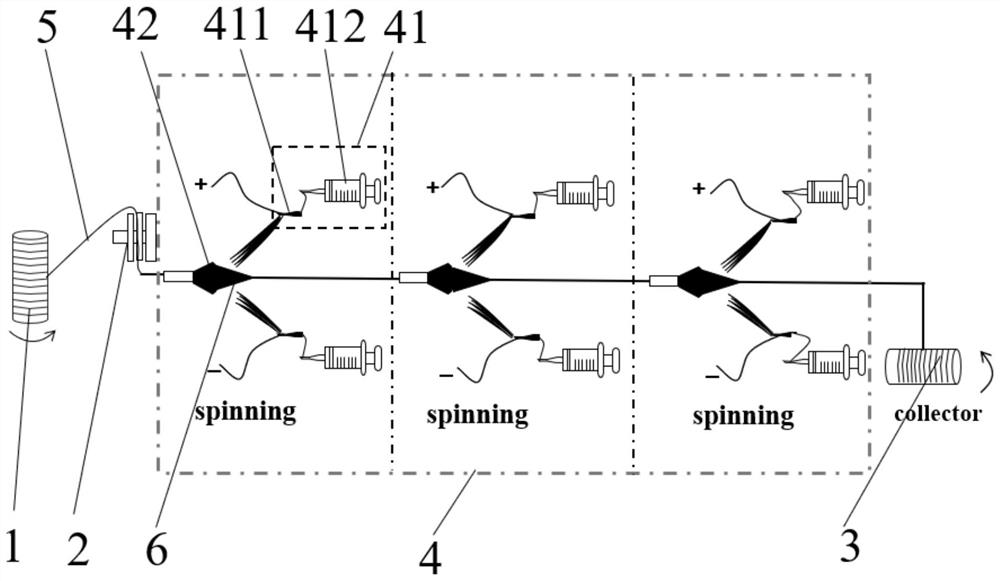

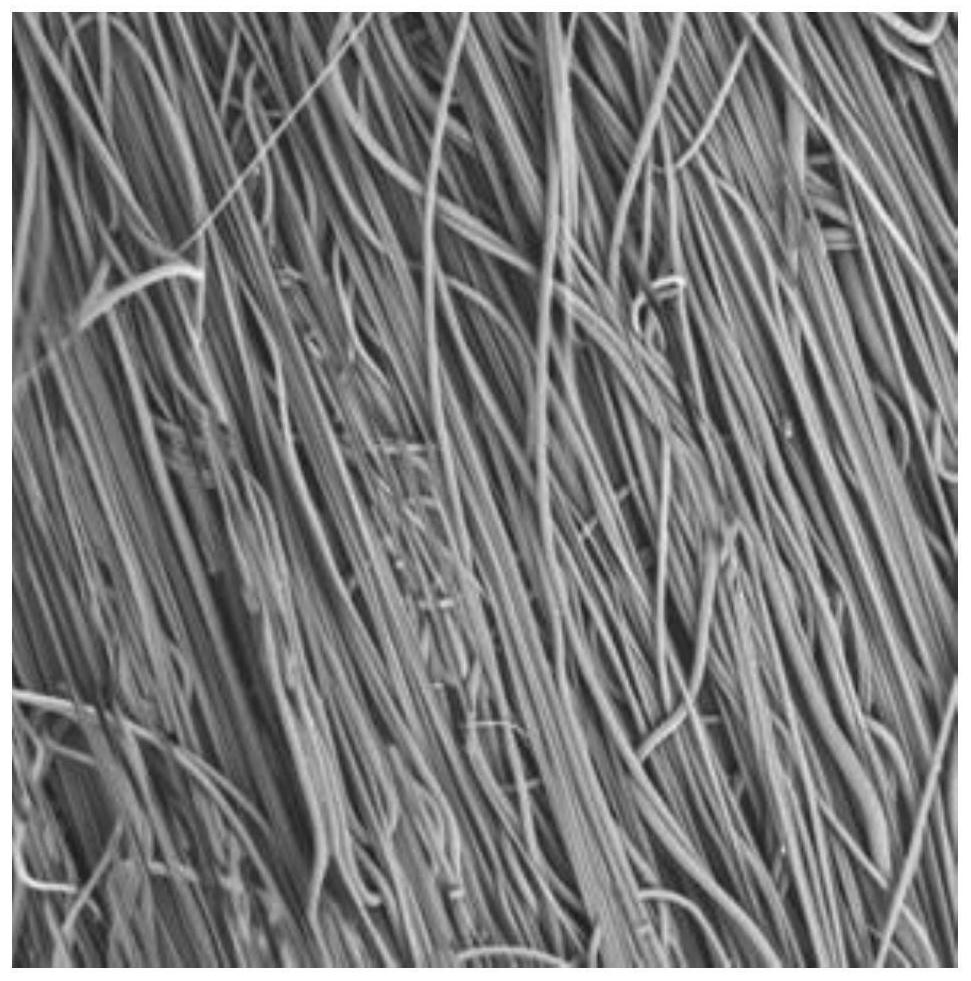

[0038] Step 1. Prepare a composite yarn with piezoelectric properties. The core yarn 5 is made of silver-plated nylon yarn with conductive properties. The skin layer adopts three gradients, that is, three layers of skin layers, all of which are PVDF. wire module 4;

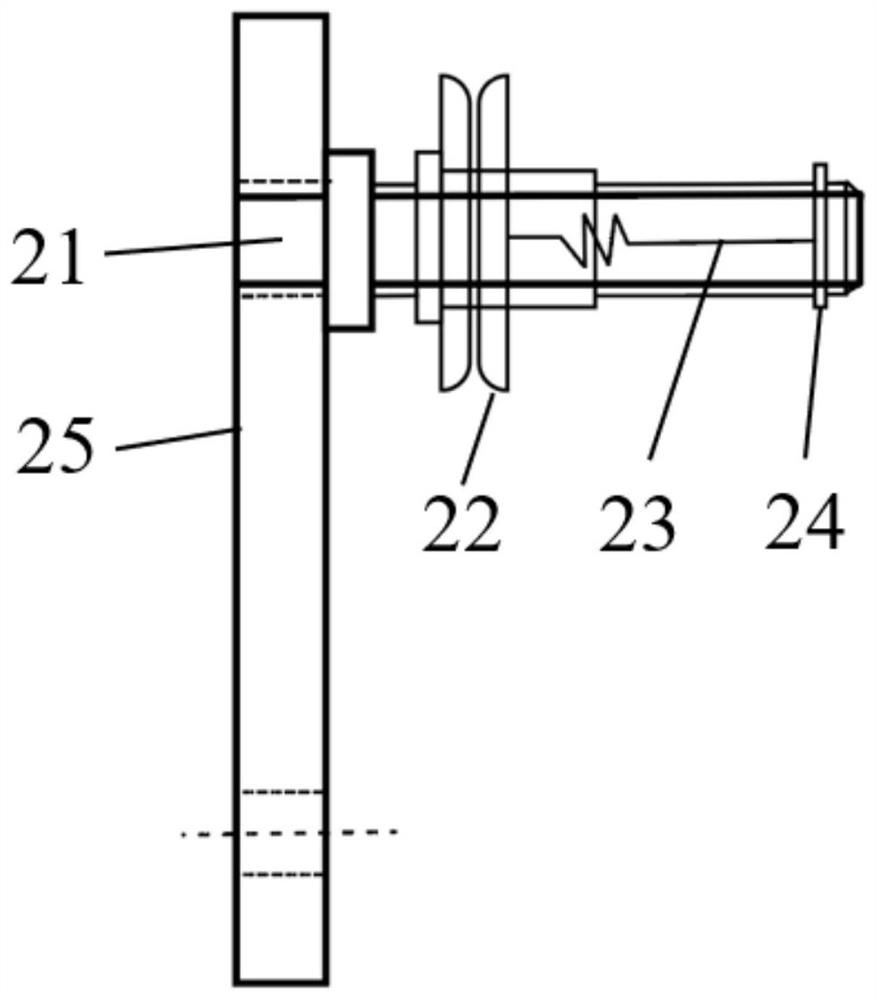

[0039] Step 2. Configure a PVDF solution with a concentration of 10 wt% as the spinning solution, and then use all the syringes 412 in the three spinning modules 4 to inhale the spinning solution. After fixing the syringes 412, install the spinning needle 411 on the syringe 412. On, the two spinning needles 411 of the same spinning module 4 are respectively connected to the positive and negative electrodes of the DC power supply; the core yarn 5 is released from the unwinding device 1, and passes through the entire modular spinning assembly via the tensioning device 2, And fixed on the collection device 3;

[0040] Step 3. Set the moving speed of the core yarn 5 to 0.2mm / s, the feed rate of the spinning solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com