High-voltage electric pulse ignition type electronic detonator

A high-voltage electric pulse and electronic detonator technology, which is used in offensive equipment, fuzes, weapon accessories, etc., can solve problems such as long drying time, component volume constraints, and explosion resistance, achieve energy saving and consumption reduction in work sites, and improve product quality. Reliability, the effect of reducing production risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

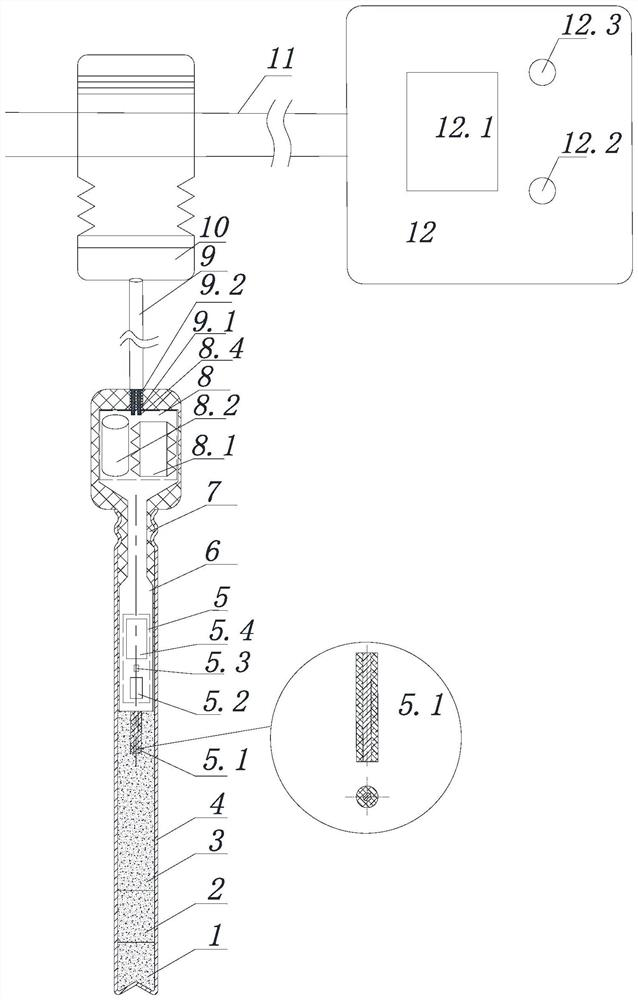

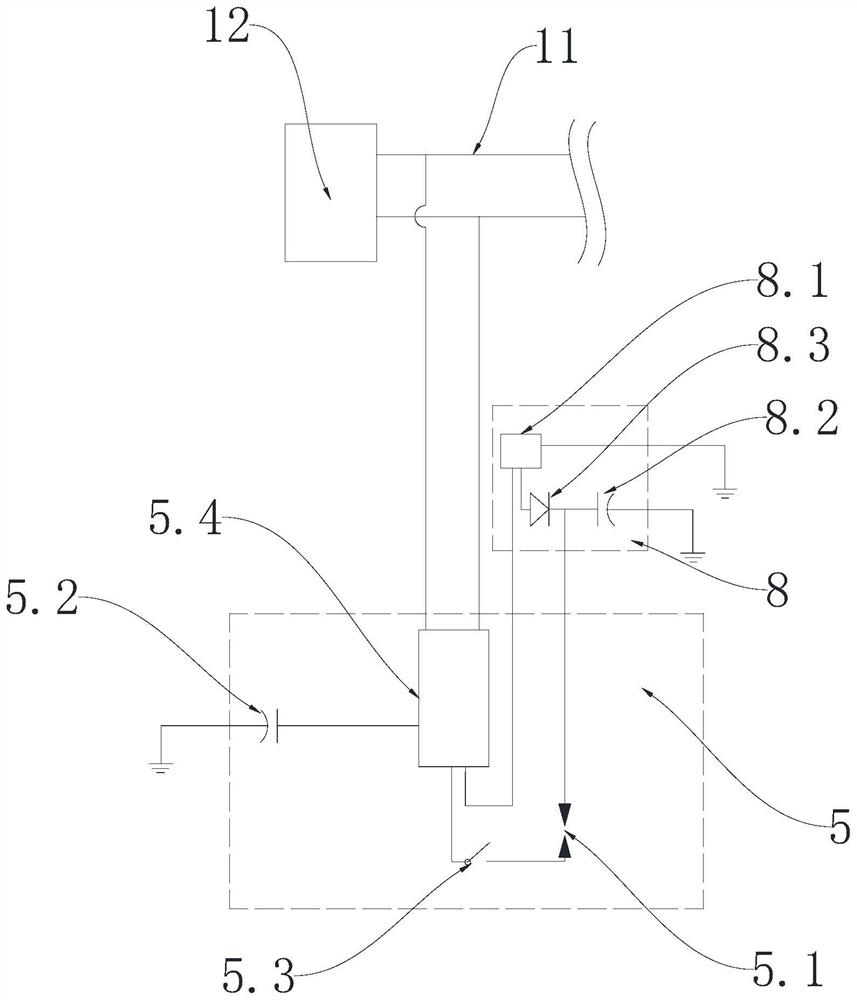

[0033] like figure 1 As shown, a high-voltage electric pulse ignition type electronic detonator mainly includes several parts, such as a basic detonator, an energy storage communication module 8, an electronic control module 5, a general control system 12, and a handheld device. The basic detonator includes a detonator tube shell 4, one end of the detonator tube shell 4 is closed, and the other end is provided with an opening, and the closed end of the detonator tube shell 4 is filled with a primary charge 1, a secondary charge 2, and a priming charge 3 in turn, or A reinforcing cap is added to the detonator, an electronic control module 5 is also arranged inside the detonator casing 4, and an energy storage communication module 8 and a general control system 12 are arranged outside the detonator casing 4; the electronic control module 5 includes an ignition needle. 5.1. Working capacitor 5.2, ignition switch 5.3 and microcontroller 5.4, the ignition needle 5.1 is in direct co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com