Far-field eddy current probe and method for dissimilar steel weld defect detection

A defect detection and far-field eddy current technology, which is applied to measuring devices, greenhouse gas reduction, instruments, etc., can solve the problems of easy initiation of hazards, insufficient detection efficiency, and narrow detection space, so as to improve the efficiency of defect detection and improve the efficiency of defect detection. Probability, the effect of avoiding signal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

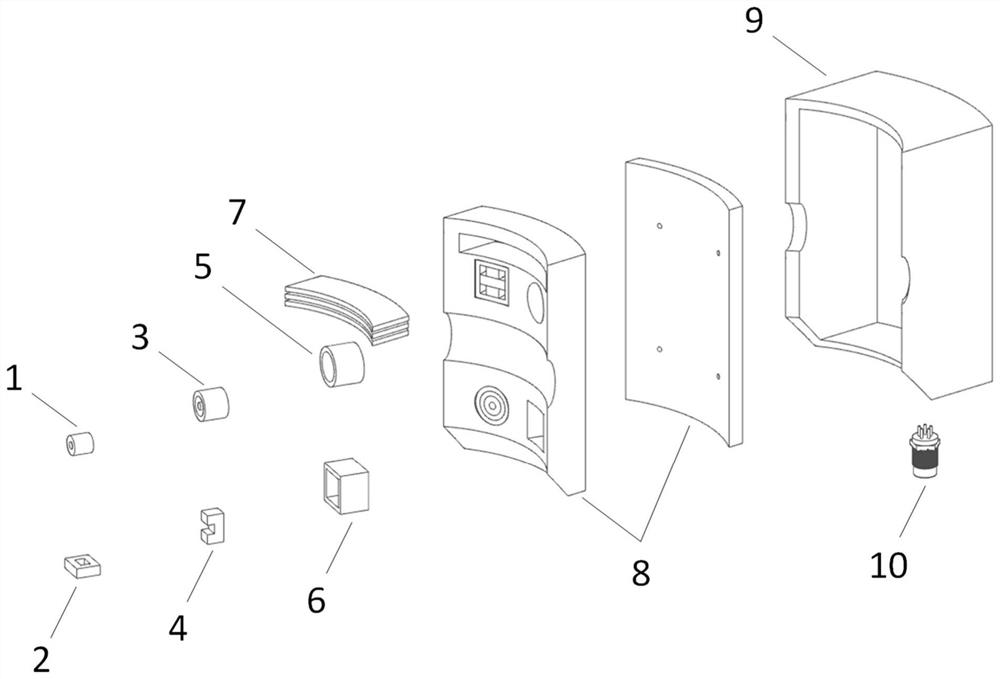

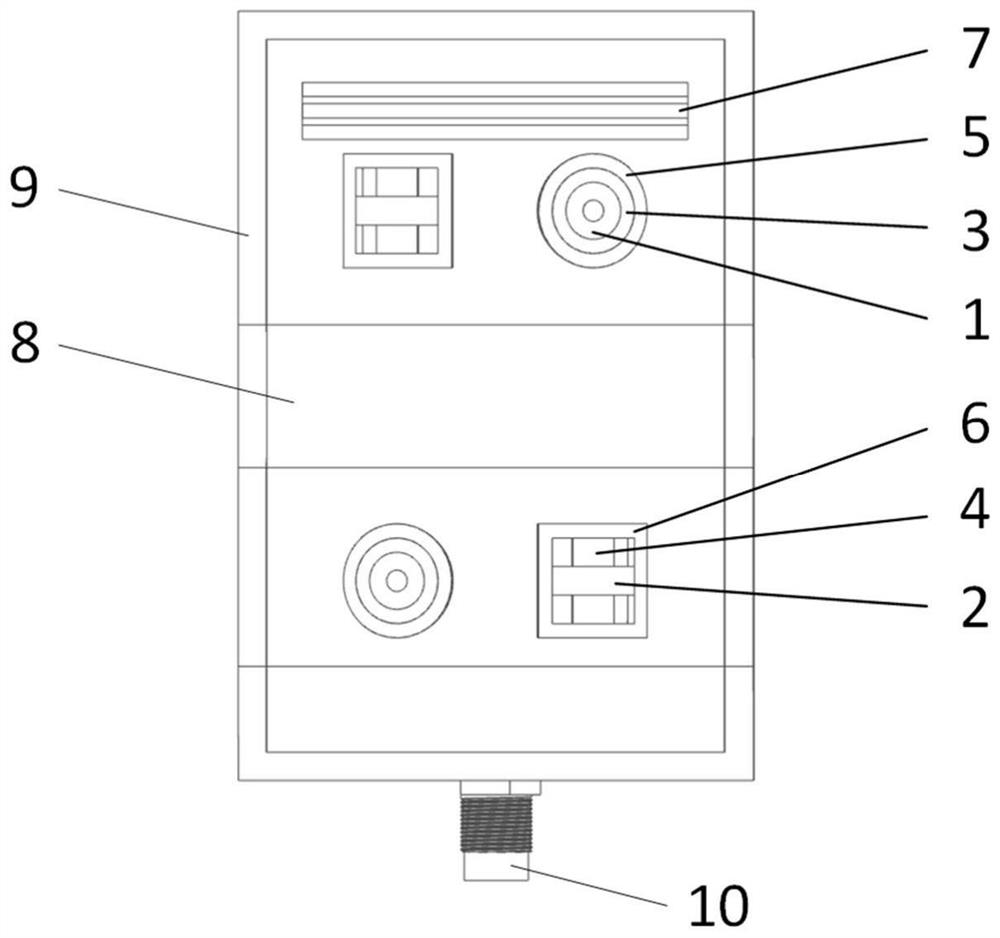

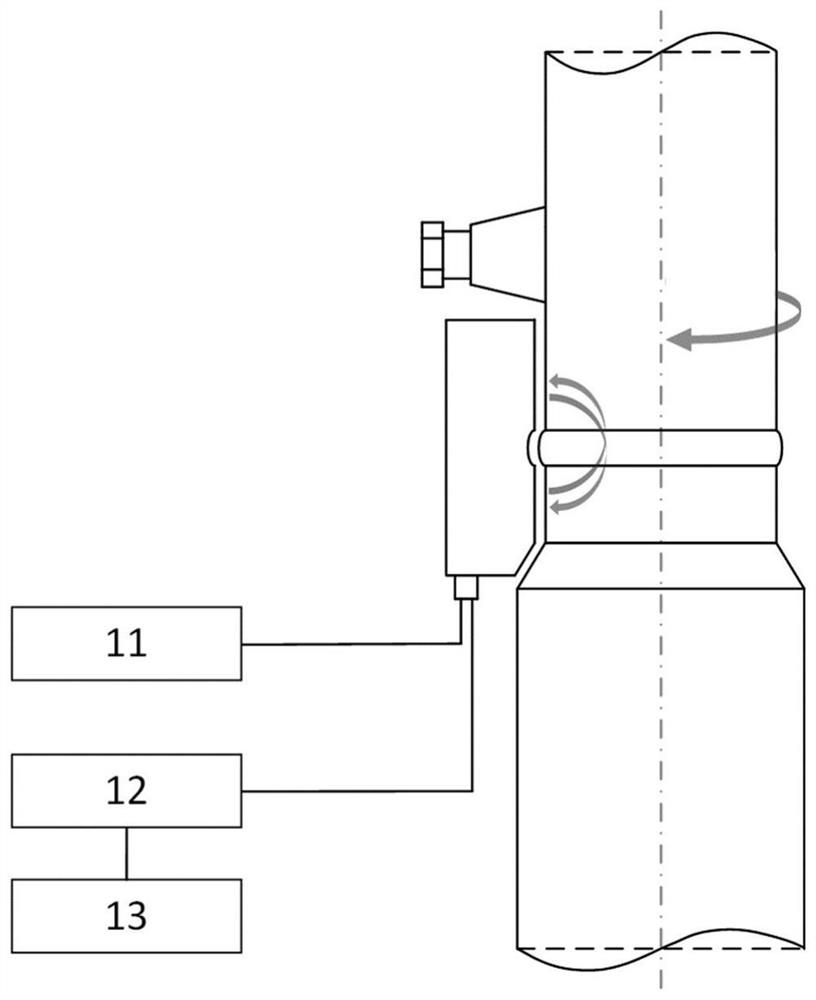

[0052] A far -field vortex probe and method for the detection of a variety of steel weld defects in the present invention are The heterogeneous steel weld is detected. Among them, the weld width is 12mm, the upper part of the material is T91, and the lower part of the material is TP347. There is a thermocouple fixed measurement point at 30mm above the weld. for The variable diameter segment; put the far -field vortex probe on the surface of the inspection pipeline. The arc groove of the center of the probe center is matched with the pipe weld. Rotating and scanning, the welding seam deep -defective vortex impedance plane map is Figure 4 Show.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com