Heat exchanger

A heat and heat dissipation unit technology, applied in the field of heat exchangers, can solve the problems of complex structure, difficult lightweight structure, complex heat exchanger structure, etc., and achieve the effects of low manufacturing cost and high bending rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

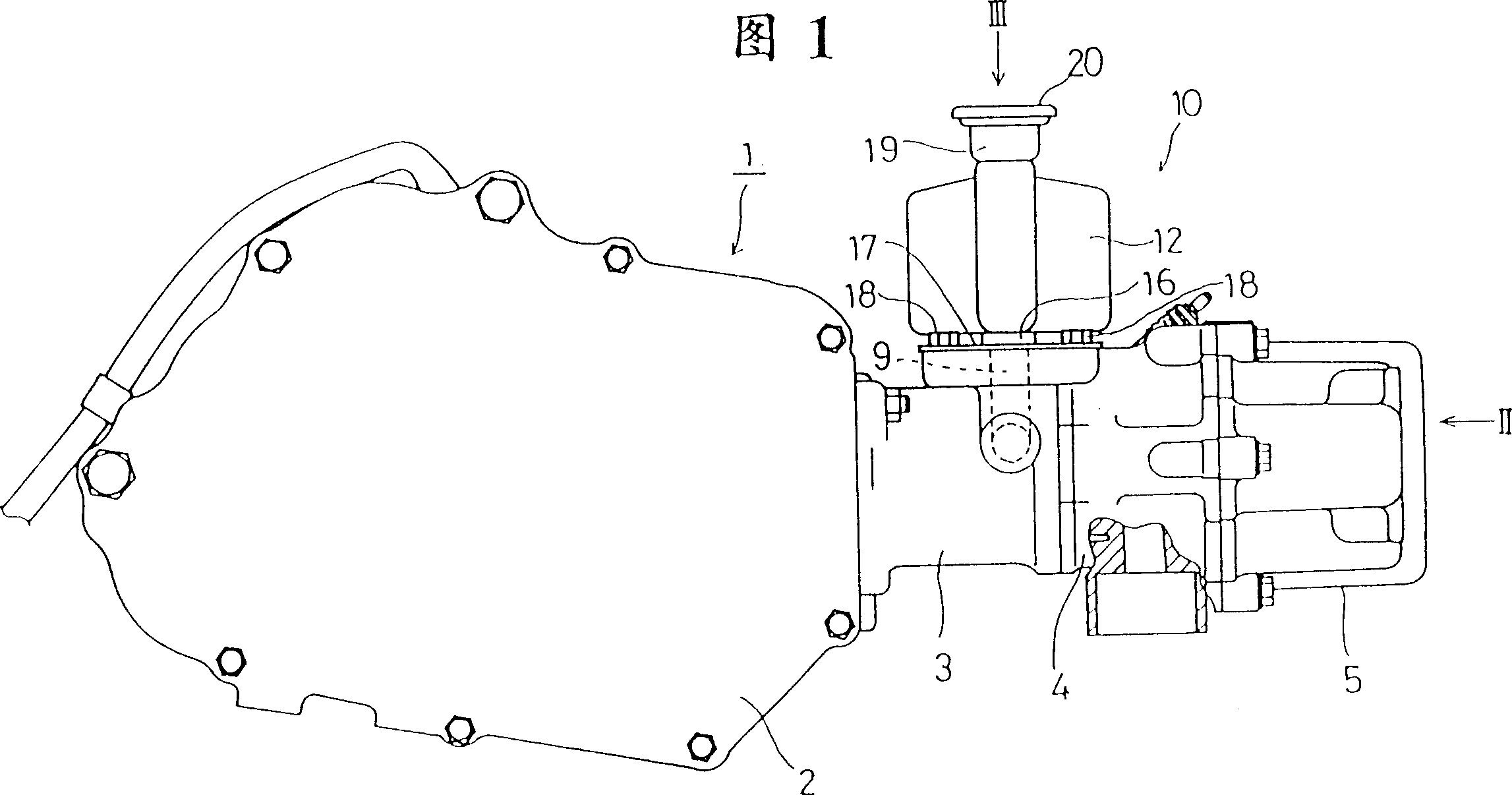

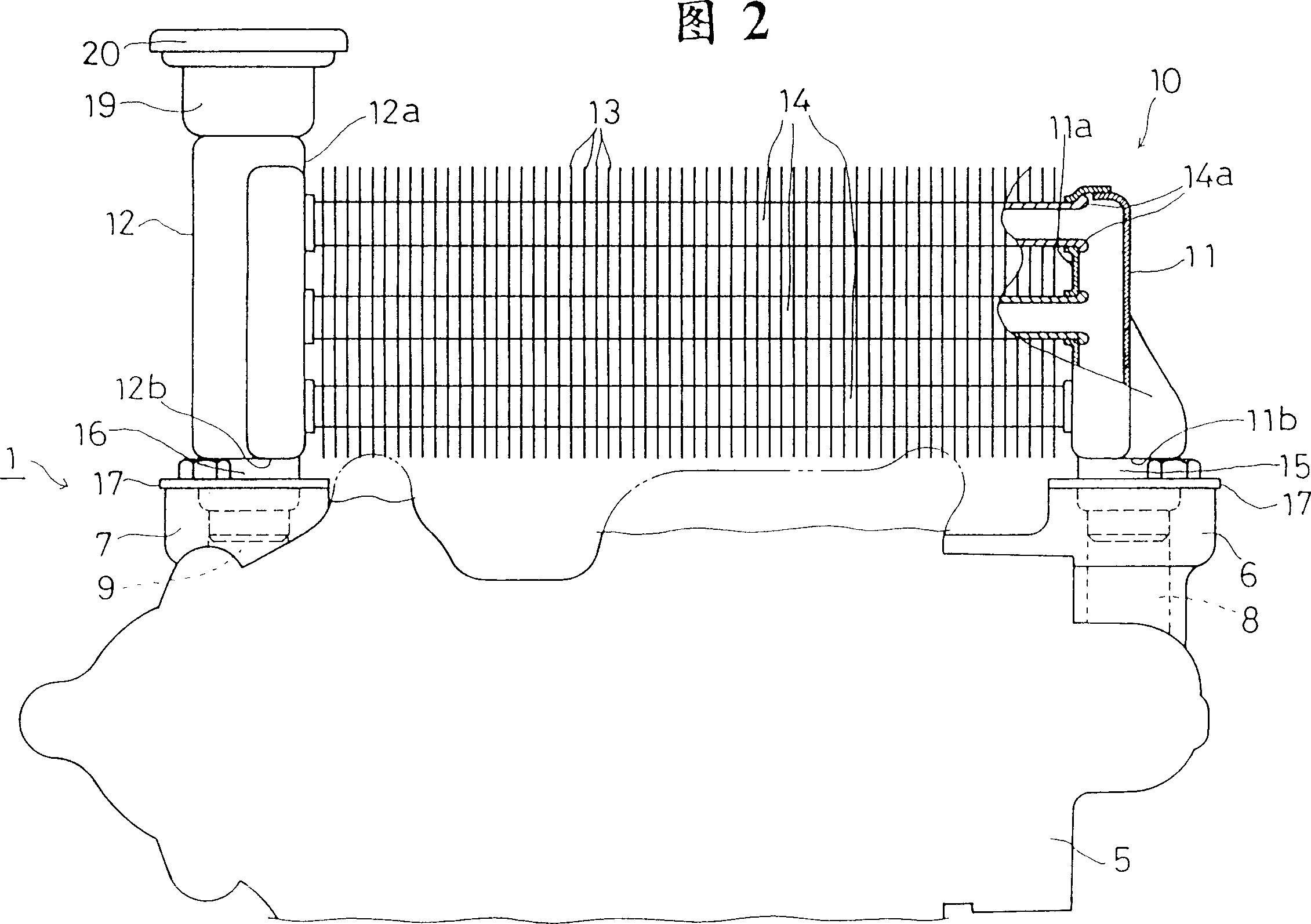

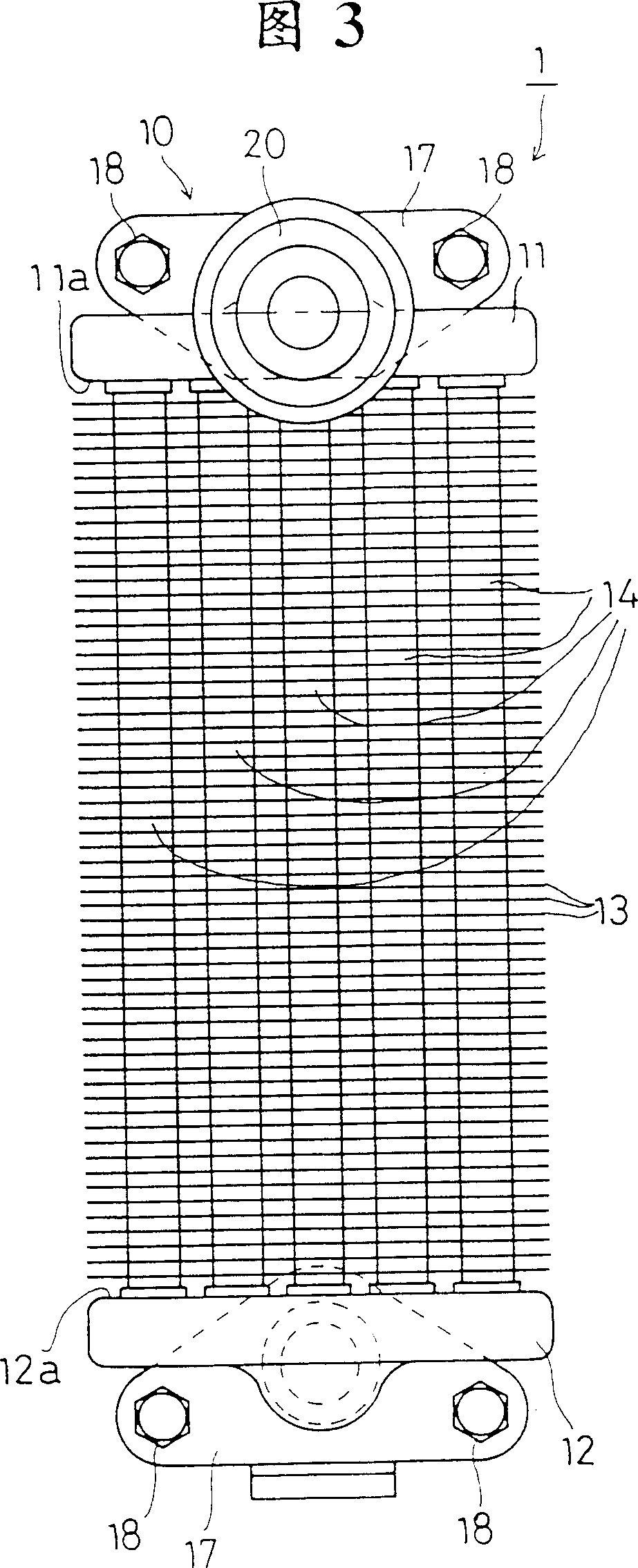

[0017] A heat exchanger according to a first embodiment of the present invention will now be described with reference to FIGS. 1 to 3. FIG. A four-stroke cycle, single-cylinder water-cooled internal combustion engine (hereinafter referred to simply as "water-cooled internal combustion engine") 1 is mounted on a small motorcycle including two wheels, three wheels or four wheels for uneven land. The water-cooled internal combustion engine 1 has a split crankcase 2 , a cylinder block 3 , a cylinder head 4 and a cylinder head cover 5 . A cylinder block 3 is attached to the front end of the crankcase 2, the central axis of a cylinder hole (not shown) made in the cylinder block 3 extends longitudinally substantially horizontally, and the cylinder head 4 and the cylinder head cover 5 are assembled in this order. Placed on the front end of the cylinder block 3, the cylinder block 3, the cylinder head 4 and the cylinder head cover 5 are all fastened on the crankcase 2. The cylinder bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com