Airflow jetting equipment for drying slurry and paste

A technology of jet airflow and drying treatment, which is applied in the direction of drying solid materials, lighting and heating equipment, heating to dry solid materials, etc., can solve the problems of time-consuming, large loss of organic components of sludge, and high energy consumption, etc. The effect of advanced economic indicators, easy large-scale operation, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

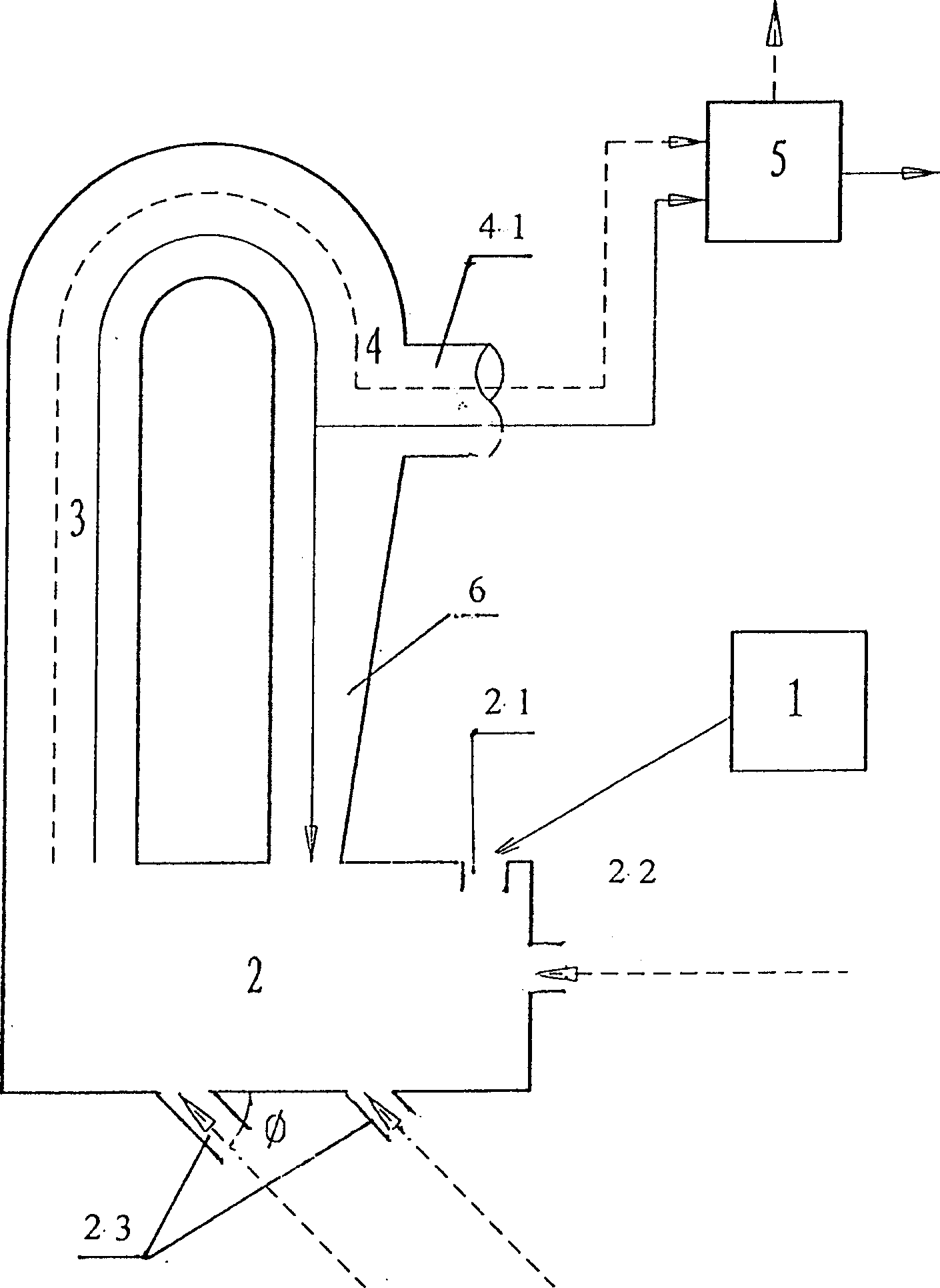

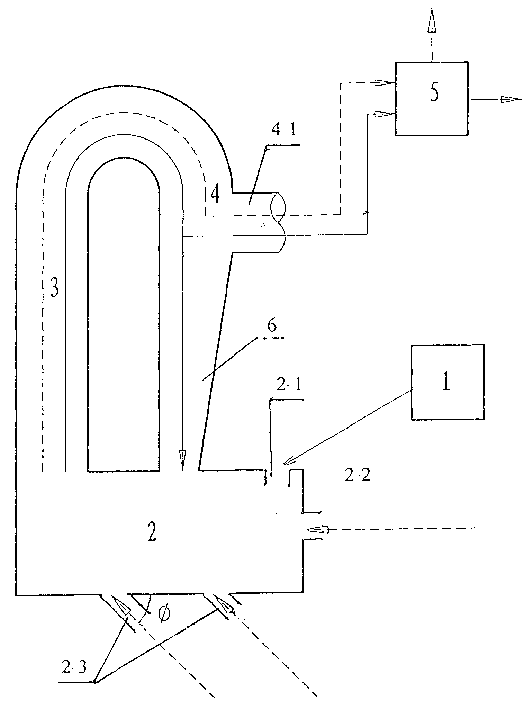

[0020] As shown in Figure 1: the main body of the dryer is composed of a crushing and drying chamber 2, a gas-solid conveying pipeline 3, a gas-solid coarse separator 4, a gas-solid coarse separation outlet 41 and a gas-solid separation system 5 connected thereto. The solid conveying pipe 3 and the gas-solid coarse separator 4 are actually an inverted U-shaped pipe, the lower opening of which communicates with the crushing and drying chamber, the vertical pipe 3 away from the material inlet serves as the gas-solid conveying pipe, and the vertical pipe near the material inlet The pipe is used as a material return port, and its upper end is provided with a gas-solid coarse separation outlet 41 to communicate with the gas-solid separation system. Due to gravity and the direction of the gas-solid coarse separation outlet forms a certain angle with the vertical pipe on the side of the pipe, so that this area A gas-solid rough separator (zone) is formed. The hot air medium introduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com