Preparation method of plant-derived amino polypeptide water-soluble fertilizer

An amino acid, water-soluble fertilizer technology, applied in nitrogen fertilizer and other directions, can solve the problems of high salinity, the existence of carcinogens, and many by-products, and achieve the effects of simple and efficient preparation process, reduction of carcinogens, and high biological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

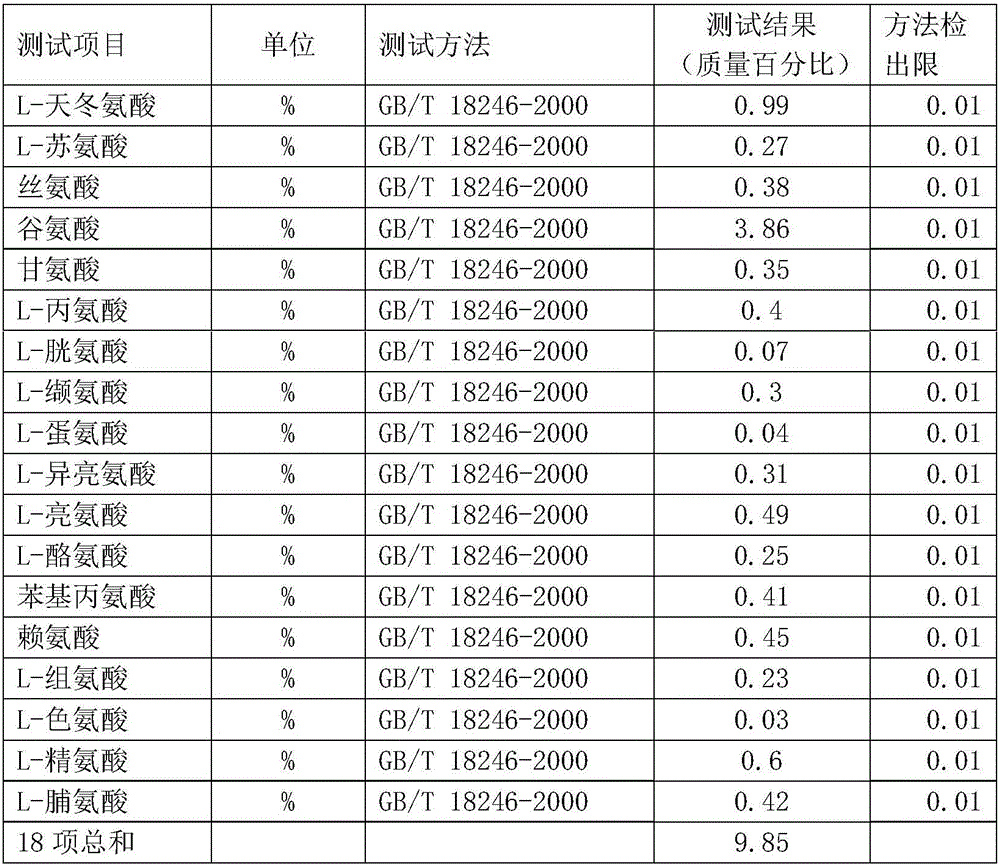

Embodiment 1

[0011] A method for preparing plant-derived amino acid polypeptide water-soluble fertilizer, comprising the following steps:

[0012] A. Weigh the soybean meal and water according to the mass ratio of 1:4, put them into the reaction kettle, stir and mix evenly, grind and beating, sieve through 60 meshes, adjust the pH to 3.0 with hydrochloric acid, and keep the temperature at 45°C for 2 hours to obtain soybean meal slurry;

[0013] B. Add acid pectinase to the soybean pulp obtained in step A, the addition of the acid pectinase is 0.1% of the soybean pulp quality, and after 3 hours at 45°C, adjust the pH of the slurry in the reactor to 4.5 with potassium hydroxide Add phytase, the addition of described phytase is 0.7% of soybean meal pulp quality, 50 ℃ of insulations 1 hour, then boiling water bath 20 minutes, the last temperature is down to 50 ℃ of insulation standby; Add α-amylase, all The addition of the above-mentioned α-amylase is 0.3% of the soybean pulp quality, and acid...

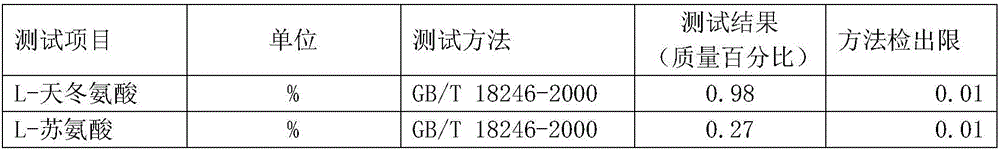

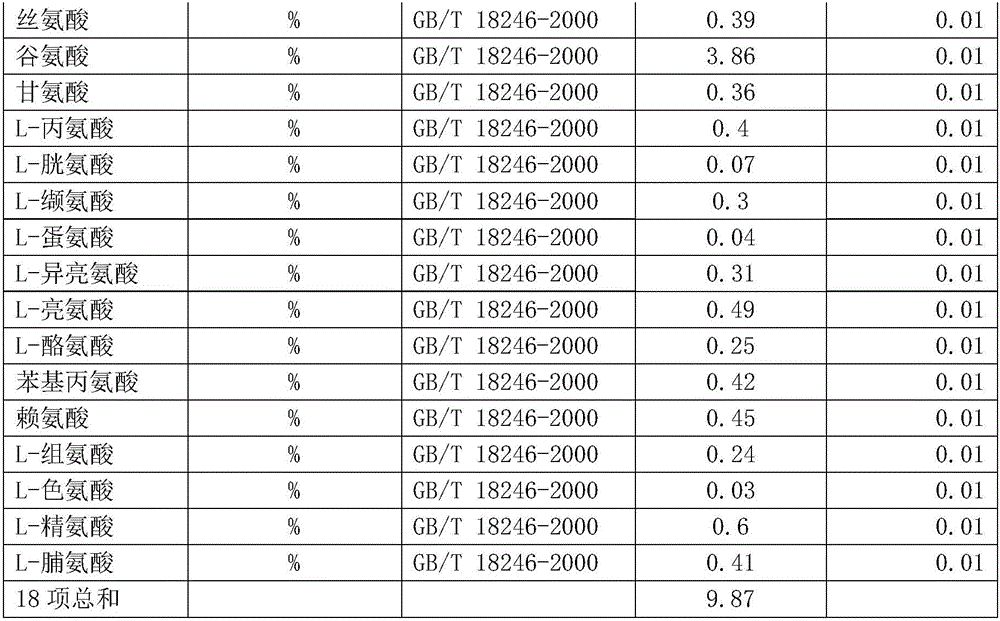

Embodiment 2

[0018] A method for preparing plant-derived amino acid polypeptide water-soluble fertilizer, comprising the following steps:

[0019] A. Weigh the peanut meal and water according to the mass ratio of 1:4, put them into the reaction kettle, stir and mix evenly, grind and beat the pulp, adjust the pH to 3.0 with hydrochloric acid after sieving with 60 mesh, and keep it warm at 45°C for 2 hours to obtain peanut meal pulp;

[0020] B, add acid pectinase in step A gained peanut pulp, the add-on of described acid pectinase is 0.1% of peanut pulp quality, after 45 ℃ of insulations 3 hours, adjust the slurry pH in the reactor with potassium hydroxide To 4.5; add phytase, the addition of said phytase is 0.7% of the mass of peanut pulp, keep warm at 50°C for 1 hour, then boil in water for 20 minutes, and finally drop the temperature to 50°C and keep warm for later use; add α‐starch enzyme, the addition of the α-amylase is 0.3% of the quality of the peanut pulp, and after 1 hour of incub...

Embodiment 3

[0026] A method for preparing plant-derived amino acid polypeptide water-soluble fertilizer, comprising the following steps:

[0027] A. Weigh rapeseed meal and water according to the mass ratio of 1:4, put them into the reaction kettle, stir and mix evenly, grind and beat, sieve through 60 meshes, adjust the pH to 3.0 with hydrochloric acid, and keep warm at 45°C for 2 hours to obtain rapeseed meal pulp ;

[0028] B, add acid pectinase in step A gained rapeseed pulp, the add-on of described acid pectinase is 0.1% of the quality of rapeseed pulp, after 45 ℃ of insulations 3 hours, adjust in the reactor with potassium hydroxide Slurry Ph to 4.5; add phytase, the amount of phytase added is 0.7% of the quality of rapeseed pulp, 50 ° C for 1 hour, then boiled water bath for 20 minutes, and finally the temperature is reduced to 50 ° C for later use; add α-amylase, the addition of said α-amylase is 0.3% of the quality of rapeseed pulp, and acid protease is added after being incubat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com