Metal organic chemical vapor deposition apparatus and deposition method

A metal-organic chemistry and vapor deposition technology, which is applied in chemical instruments and methods, post-processing devices, gaseous chemical plating, etc., can solve problems such as film difficulties, blocked film delivery pipelines, and unstable reactants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

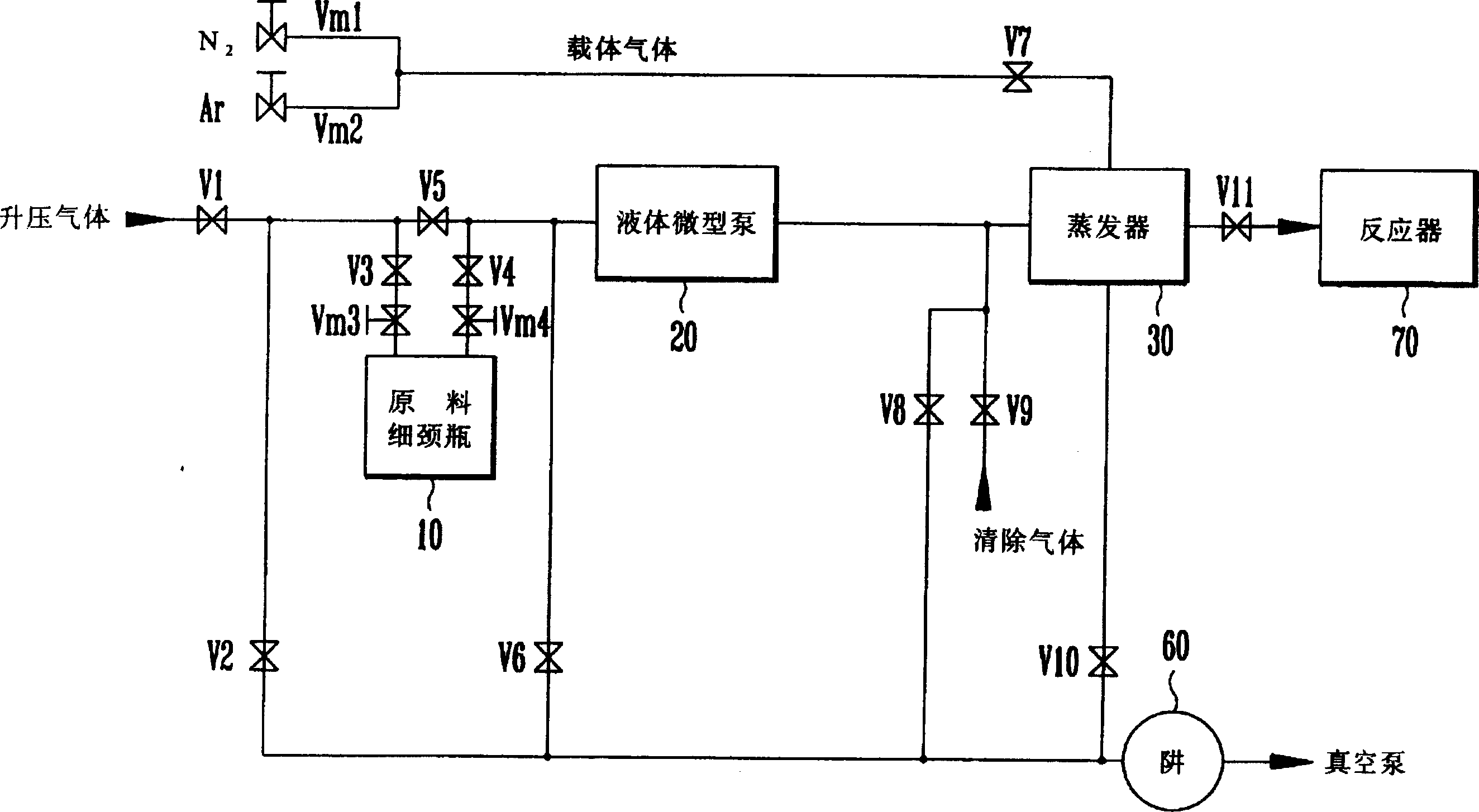

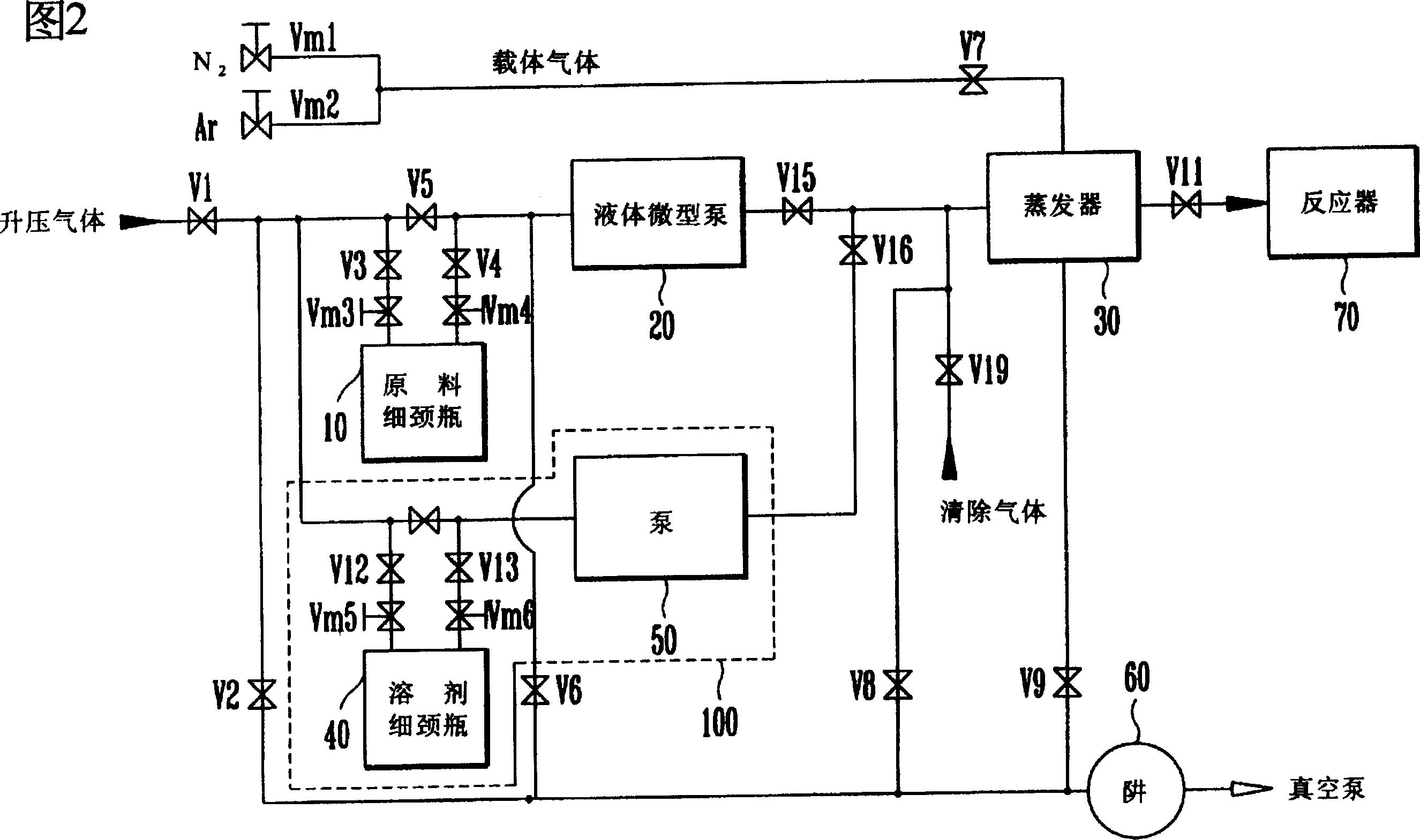

[0018] The preferred embodiments of the present invention can be better understood with reference to the accompanying drawings.

[0019] Referring to Fig. 2, it shows the MOCVD apparatus of the present invention. As shown in the figure, the MOCVD device of the present invention is the same as the conventional device in that it includes a raw material ampoule 10, a liquid micropump 20, and an evaporator for evaporating the liquid reactant that are dissolved in a solvent. 30. A reactor 70 for depositing reactants on a semiconductor substrate, a trap 60 for sealing harmful gases by cooling, and a vacuum pump, the difference is that the evaporator 30 is further equipped with a solvent supply device 100, which includes a solvent flask 40 and pump 50.

[0020] The process of forming a high dielectric film will be described below based on this diagram.

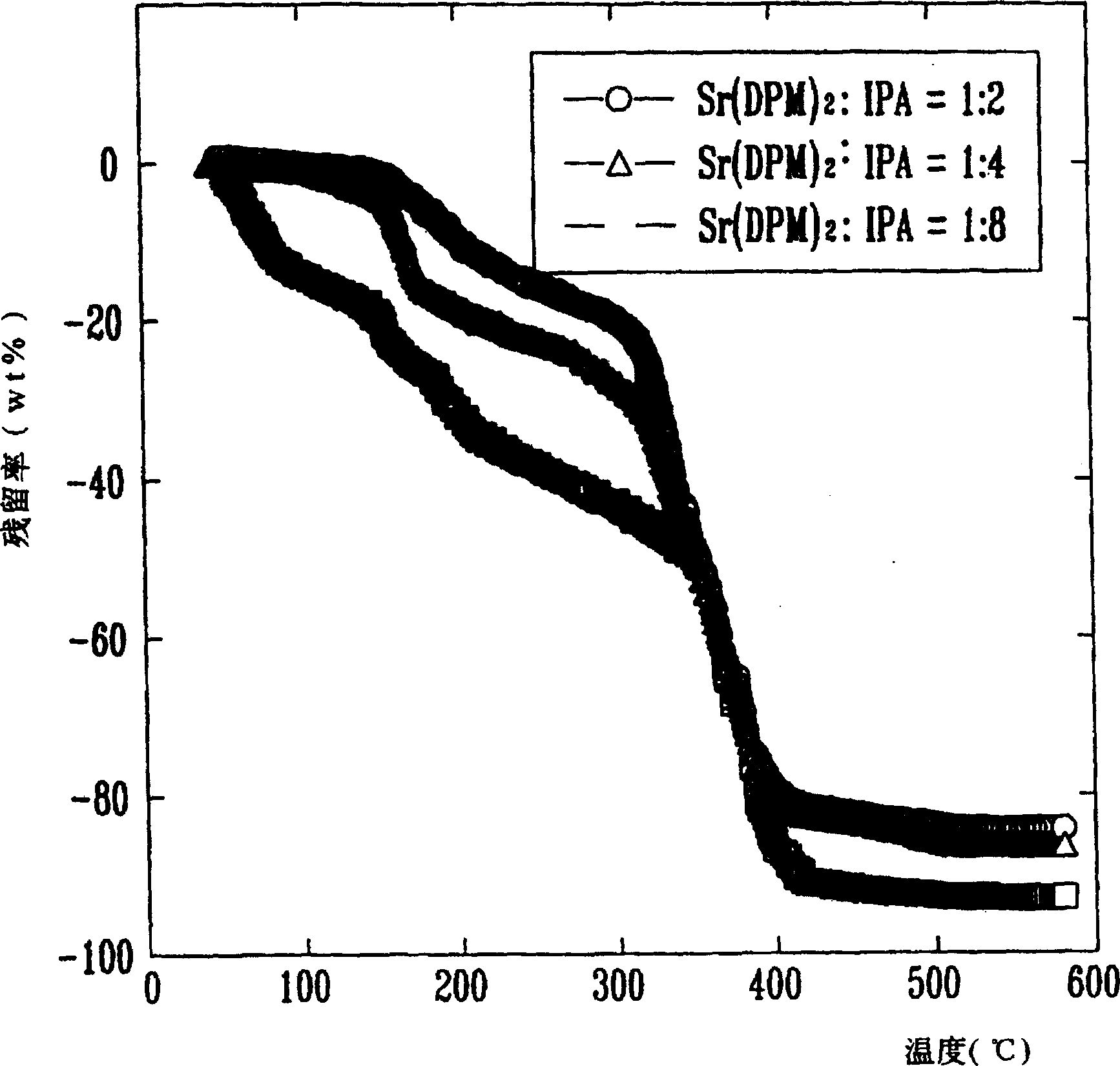

[0021] The reactant can use Ba(DPM) 2 , Sr(DPM) 2 and Ti(OC 3 h 7 ) 4 or Ti[OCH(CH 3 ) 2 ] 2 (DPM) 2 (DPM is dipivaloylm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com