Integrated continuous harmful refuse processing method and device of cracking furnace and incinerating furnace

A treatment device and treatment method technology, applied in the direction of incinerators, combustion methods, lighting and heating equipment, etc., can solve the problems of high treatment cost, difficult treatment, simultaneous occurrence, etc., achieve high standard discharge quality, reduce load, and reduce concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

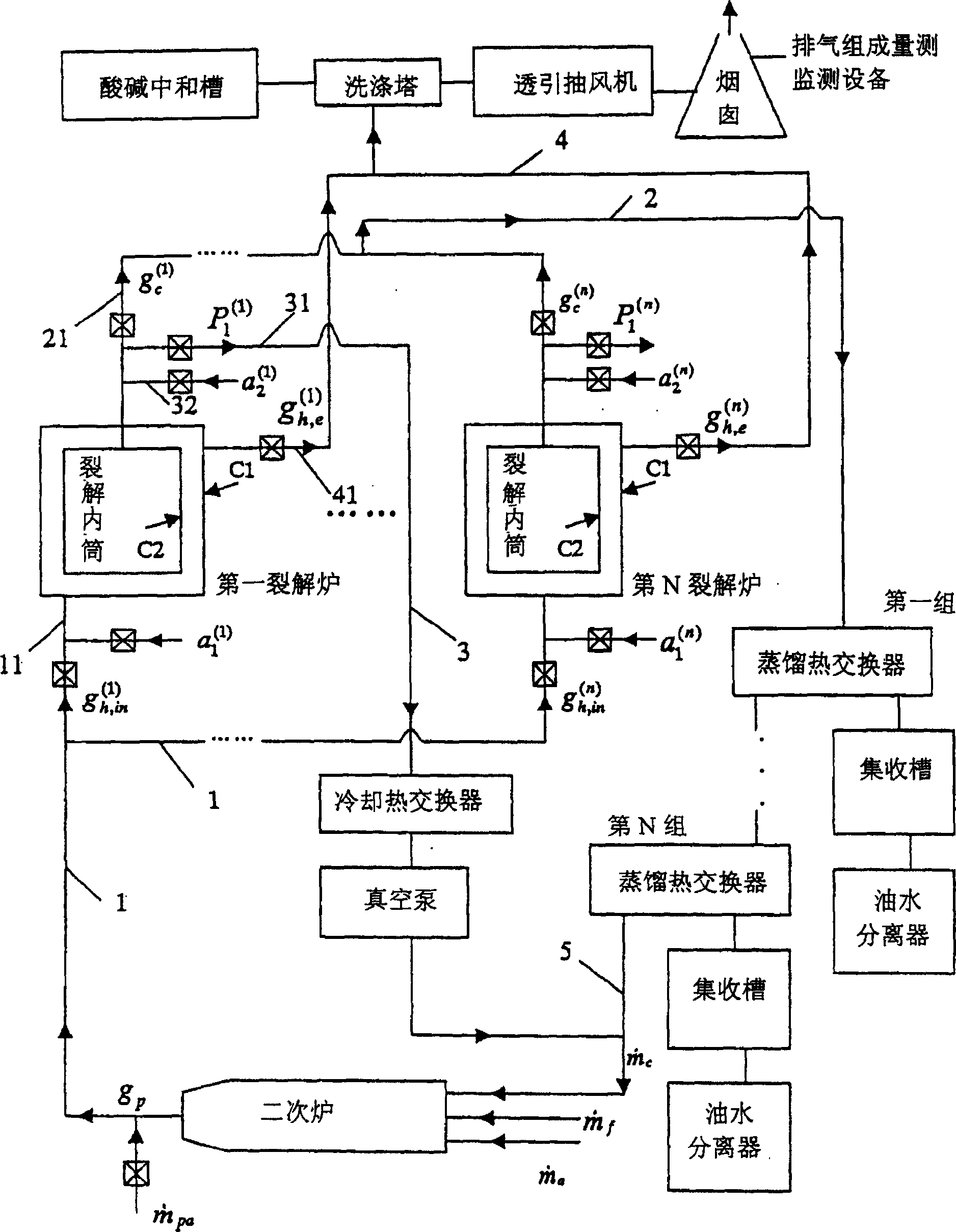

[0028] see figure 1 As shown, the present invention is composed of a secondary furnace, multiple cracking furnaces, multiple sets of distillation heat exchangers, multiple collection tanks, multiple oil-water separators, cooling heat exchangers, vacuum pumps and air pollution treatment equipment, etc. in:

[0029] The secondary furnace is connected with air and fuel flow control valves to control the proper flow of fuel and air Make it mixed and combusted in an appropriate ratio, and the hot combustion oxygen generated after combustion will first pass through a temperature control valve g p , which can be calculated to know the temperature of the hot gas required by the cracking furnace, and adjust the temperature control valve g p cold air flow In order to change the temperature of the hot gas, it is connected to the branch pipe 11 of each cracking furnace through the parallel connection of the supply pipeline 1, and each is provided with a heat supply valve g that can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com