Composite wall plate with waste textile fibre reinforced concrete side surface and its producing method

A technology of textile fibers and reinforced concrete, which is applied in the direction of layered products, building structures, building components, etc., can solve the problems of poor flexural strength of the two side panels, loss of flexural strength, easy corrosion of metal keels, etc., and achieves manufacturing costs. Low, lower material cost, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

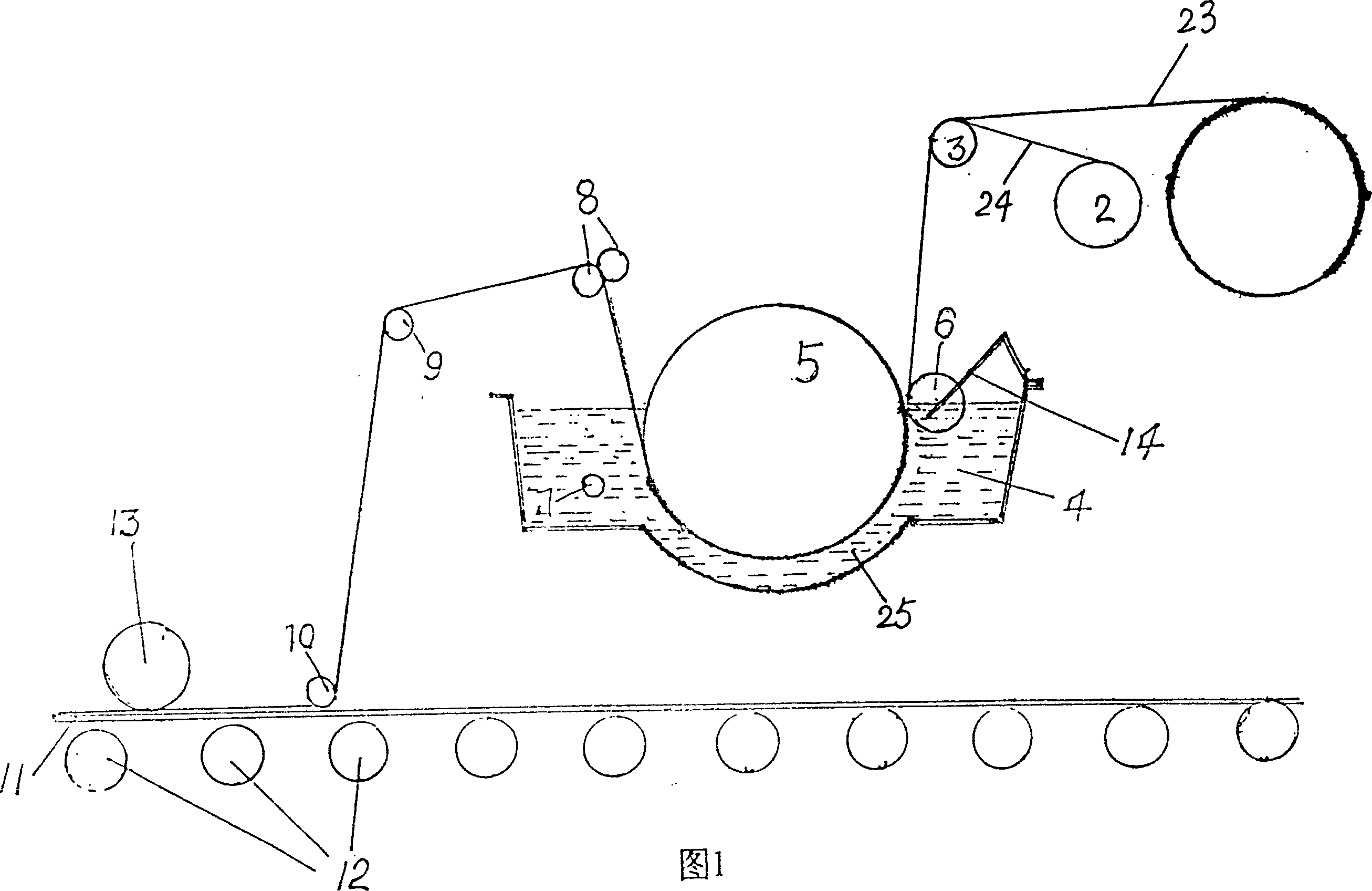

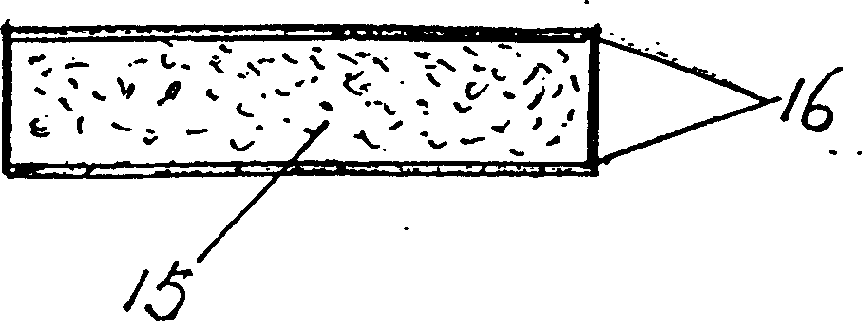

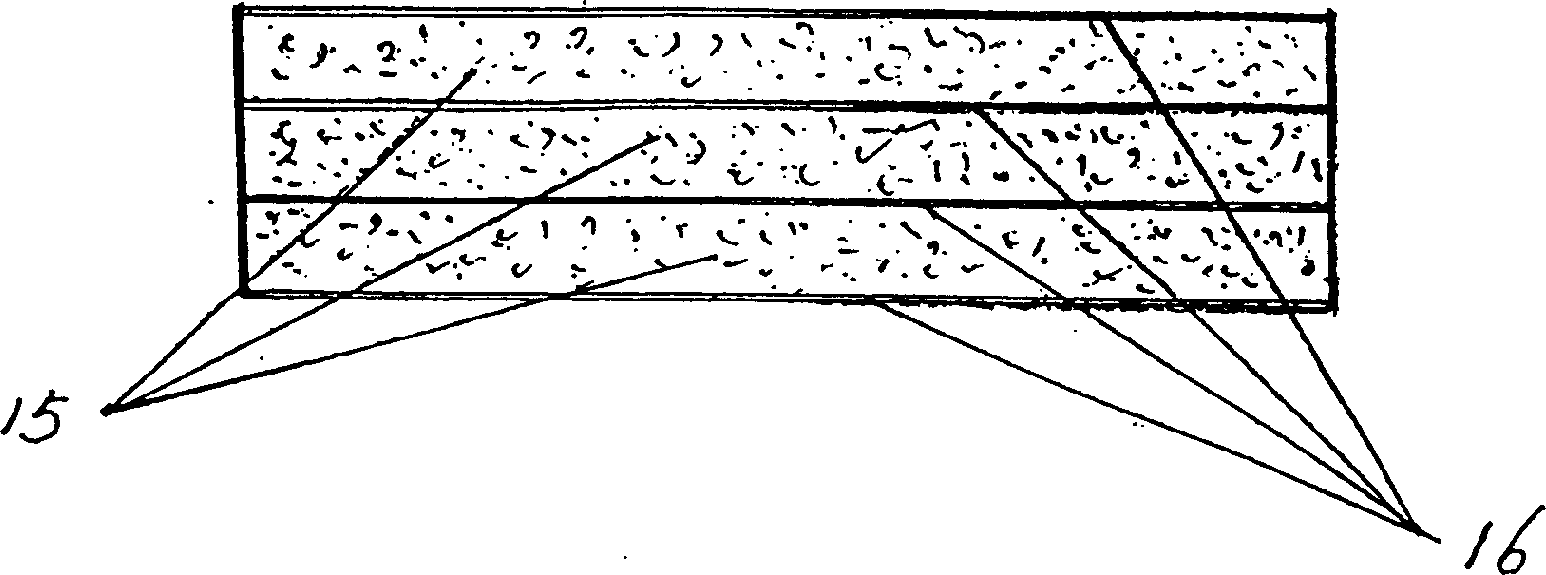

[0025] See Figure 1, figure 2 , the composite wallboard of the concrete side reinforced with waste textile fiber of the present invention, its middle layer 15 is the prior art porous plastics, mineral wool, foamed concrete or honeycomb structure (but material and manufacturing method are different, will be described in detail below ) thermal insulation material. The combination of the concrete side 16 and the middle layer 15 is through (bottom surface) vibration and (surface) rolling to make the two firmly bonded. The feature of the present invention is: the two concrete sides 16 of wallboard are made of felt 23 made of waste textile fibers and at least one layer of alkali-resistant grid glass fiber cloth 24 on its outer surface impregnated with cement slurry 25 and form. Wherein alkali-resistant glass fiber grid cloth (fiberglass c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com