Non-linear infrared inorganic optical crystal and its preparing process

A technology of nonlinear optics and crystal materials, applied to the growth of polycrystalline materials, active dielectric materials, chemical instruments and methods, etc., can solve the problems of small bandwidth of semiconductor materials, laser damage, etc., and achieve good thermal stability and air stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: CsCdBr 3 preparation

[0018] 0.81 g (4 mmol) CsBr and 1.46 g (4 mmol) CdI 2 Mixed in about 3 ml of secondary distilled water, stirred at 100 ° C for 3 hours, cooled to room temperature naturally, and gradually precipitated a large number of colorless rod-shaped crystals. Suction filtration, drying the product under infrared light.

Embodiment 2

[0019] Example 2: CsCdBr 3 single crystal growth

[0020] CsCdBr 3 The aqueous solution was placed in a 35°C incubator. Add transparent small seed crystals without obvious defects. After 1 to 2 months, a hexagonal prism-shaped transparent single crystal with a larger size is the desired crystal material.

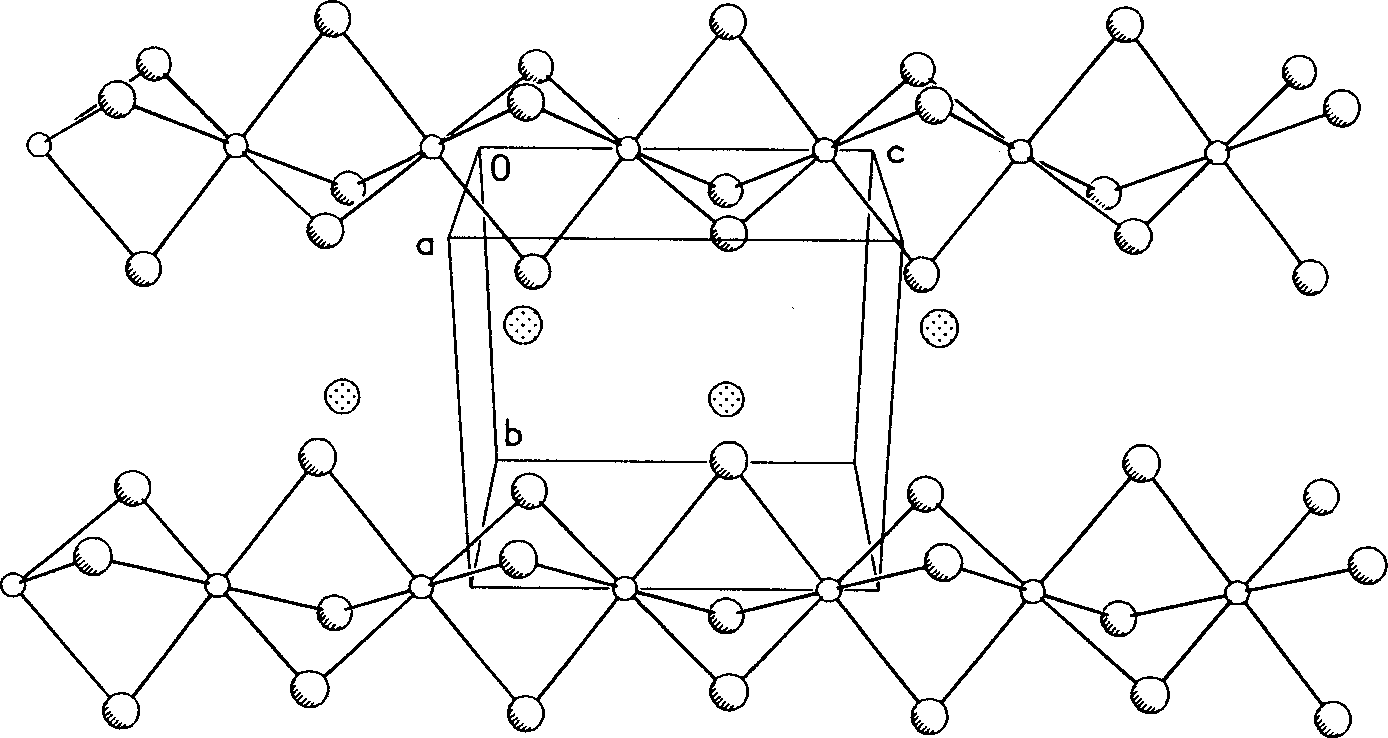

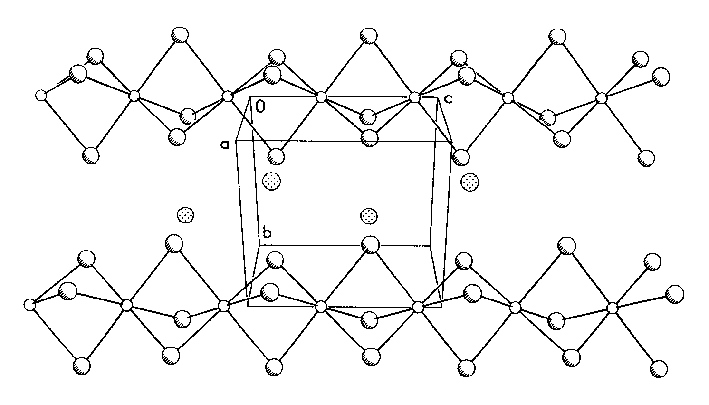

[0021] The obtained compound was determined by X-ray single crystal structure, and its crystal structure arrangement is shown in the accompanying drawing. It can be seen that the anionic groups of this compound have an octahedral configuration and form a one-dimensional chain structure through coplanarity. The bond length analysis shows that the six Cd-Br bond lengths in the octahedron are divided into two groups: 2.774 and 2.804 , with a difference of 0.03 ; and the direction of the distortion is basically the same, which is conducive to the geometric superposition of the microscopic second-order nonlinear optical effects.

Embodiment 3

[0023] CsCdBr 3 Preparation: Mix equimolar amounts of CsBr and CdI 2 Dissolve in double distilled water, reflux until the solution becomes transparent, filter, cool naturally, separate the precipitate and dry to obtain CsCdBr 3 .

[0024] CsCdBr 3 Growth of single crystals: the resulting CsCdBr 3 Put it in a container, add secondary distilled water, heat and dissolve it, put it in a constant temperature bath at 60°C, add transparent small seed crystals without obvious defects, and after 15 days, grow into a larger-sized hexagonal prism-shaped transparent single crystal. required crystal material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com