Heat insulating polyurethane wall and its construction process

A construction method and external thermal insulation technology, applied in thermal insulation, walls, building components, etc., can solve problems such as difficult control of surface flatness, poor adhesion, and easy cracking of the surface layer, and achieve poor adhesion and low thermal conductivity , The effect of easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

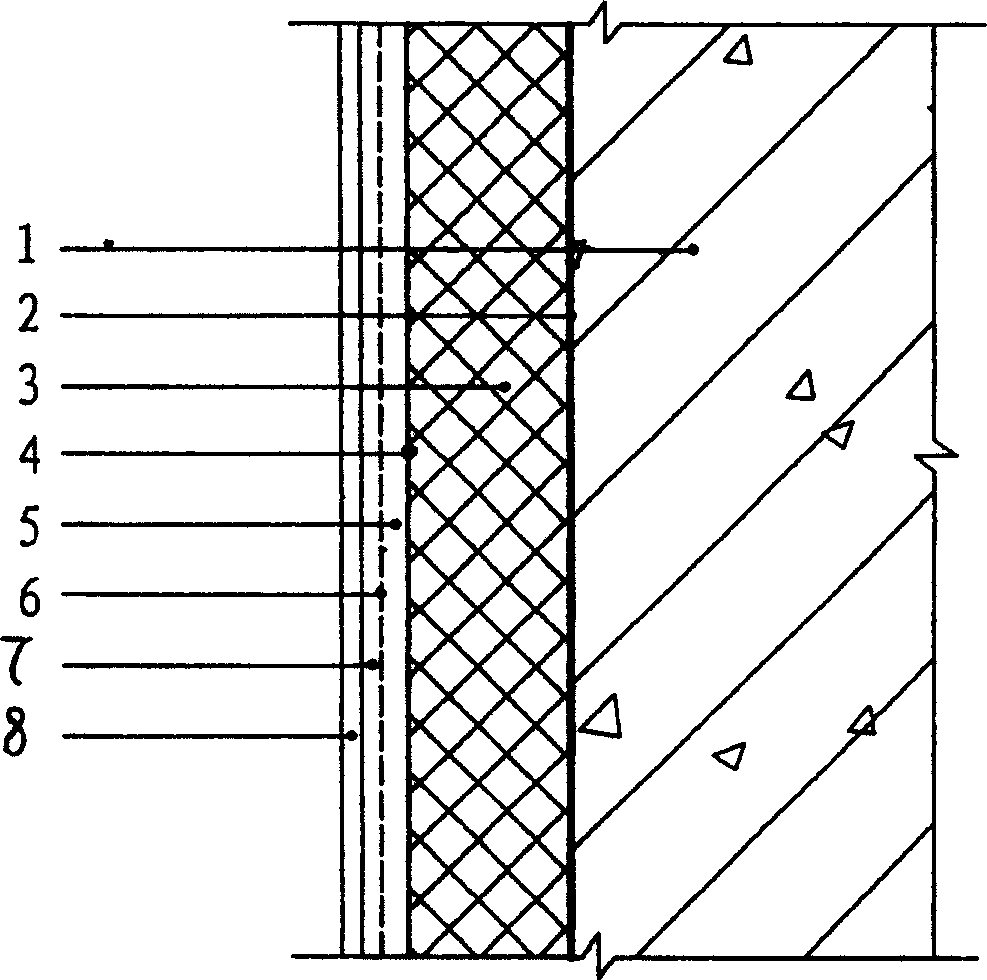

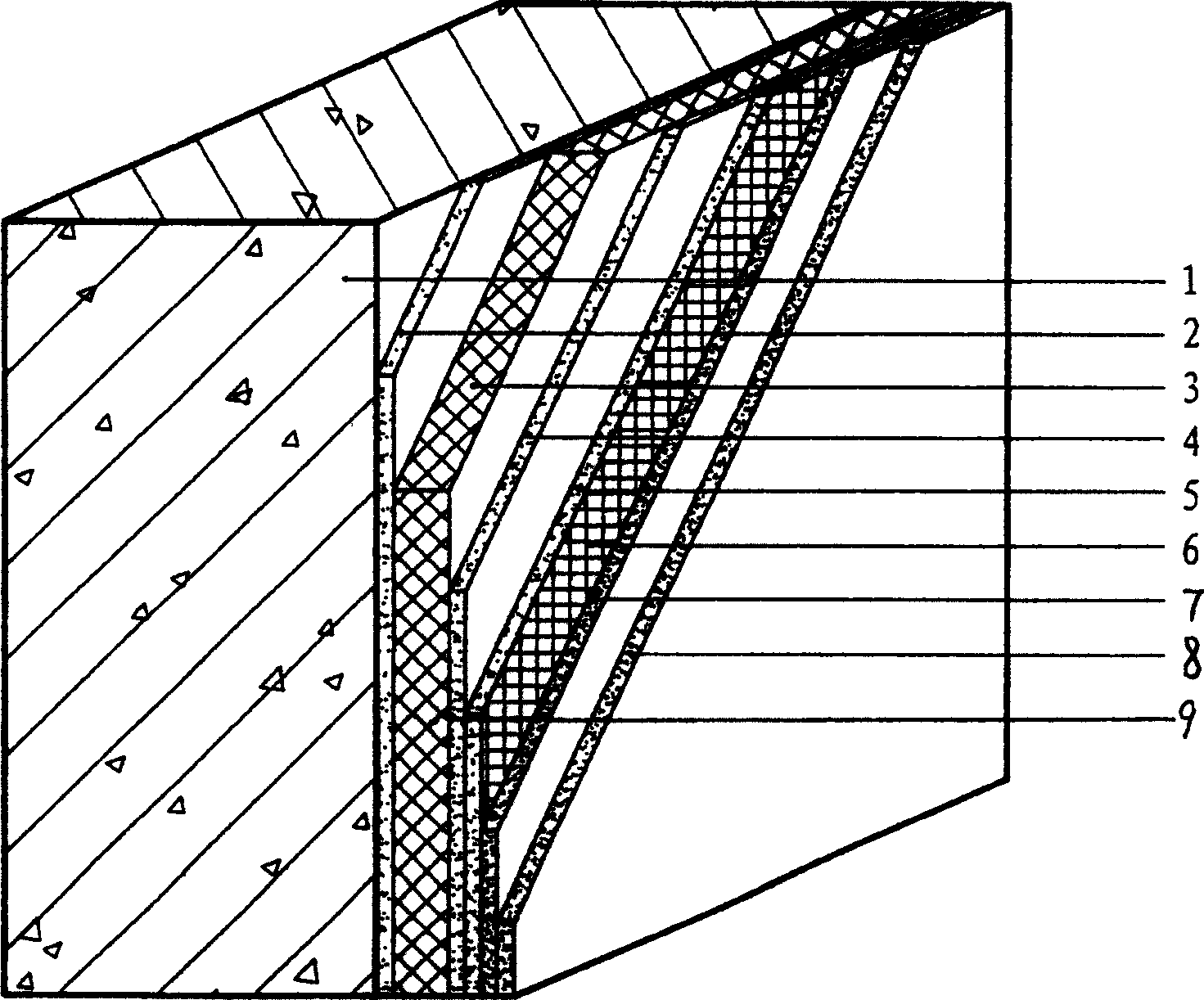

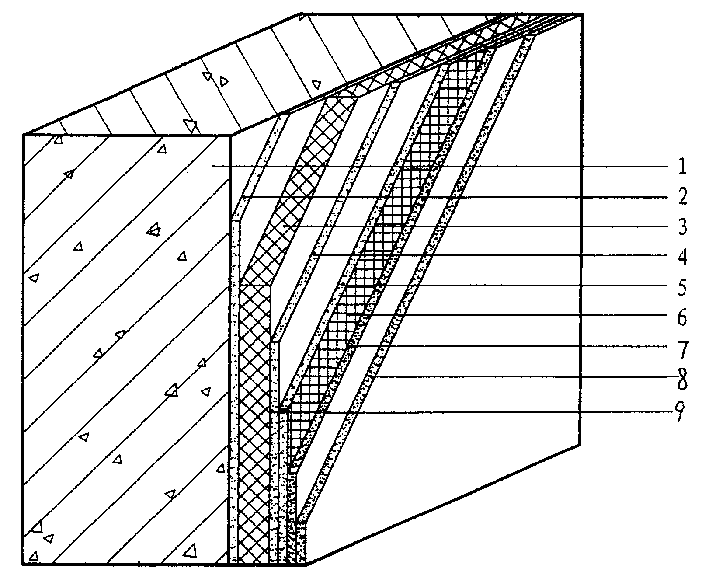

[0028] Example figure 1 , 2 shown. The polyurethane external thermal insulation wall is bonded with a layer of polyurethane primer 2 on the base layer 1, and a layer of longitude and latitude grid lines 9 is hung on the polyurethane primer. The diameter of the external longitude and latitude grid lines is less than 1.0mm. It is equal to the thickness of the insulation layer, and the small square with the longitude and latitude grid line outside is a square or rectangle with a side length less than 1m. Then the polyurethane rigid foam insulation layer 3 sprayed on site, the interface layer 4 is outside the insulation layer, the leveling layer is light plastering mortar 5 leveling, and polymer anti-cracking mortar or light plastering mortar 7 is pressed into alkali-resistant glass fiber Mesh cloth6.

[0029] The thickness of the light-weight plastering mortar layer is 5mm-25mm, preferably 5mm-10mm, and the distance between the alkali-resistant glass fiber mesh cloth and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com