Nano-carbon based film field-emission pressure sensor

A nano-carbon-based thin film and pressure sensor technology, which is applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., to achieve the effects of stable temperature characteristics, overall structure and preparation process simplification, and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

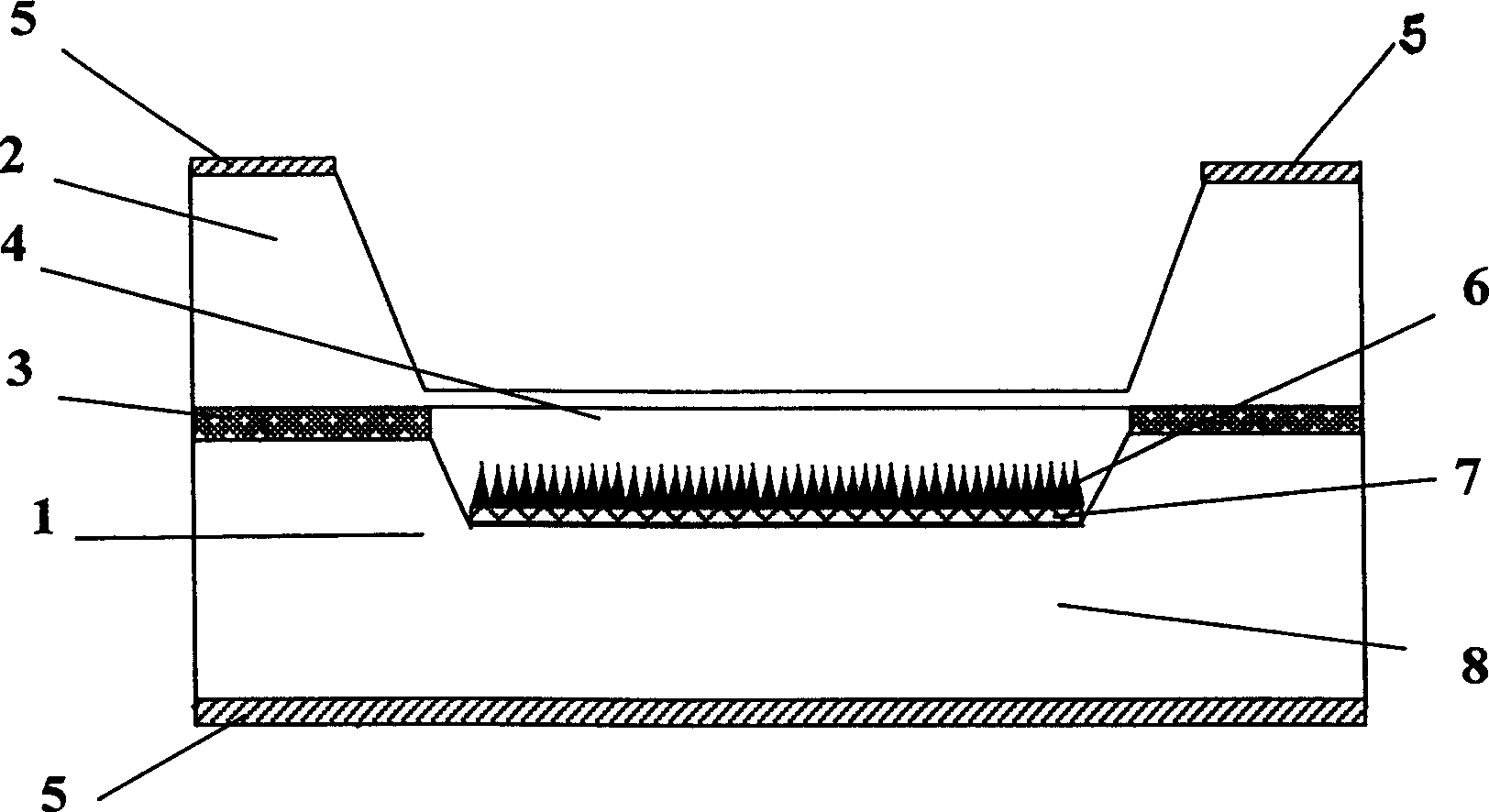

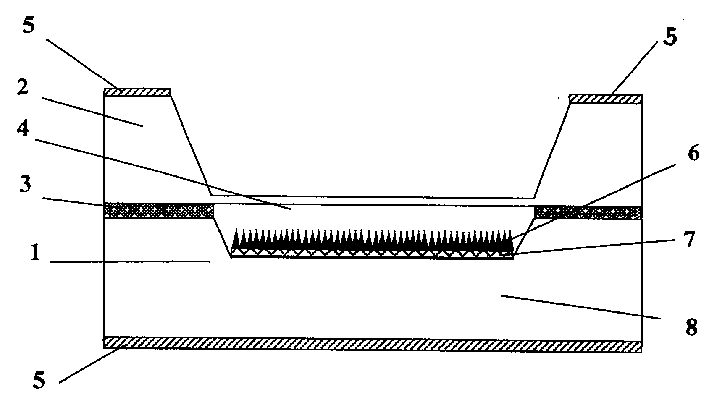

[0012] Such as figure 1 As shown, the present invention mainly includes: electron emission cathode 1, anode 2, insulating isolation layer 3, emission cavity 4 and electrode lead 5, the material of electron emission cathode 1 adopts nano-carbon-based film, and electron emission cathode 1 and anode 2 are insulated The isolation layers 3 are connected, bonded and packaged in a high vacuum environment, and a field emission cavity 4 is formed between the electron emission cathode 1 and the anode 2, and electrode leads 5 are led out from the backs of the electron emission cathode 1 and the anode 2 respectively.

[0013] The electron emission cathode 1 includes: an electron emission material 6, a thin film metal electrode 7 and a silicon substrate 8. Micromachining technology is used to etch the silicon substrate 8 to form a concave structure, and a thin film metal electrode 7 is deposited on the bottom of the concave. The thin film metal electrode The material 7 can be metals such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com