Controlled conversion of metal oxyfluorides into superconducting oxides

A technology of oxyfluoride and oxide, applied in the manufacture/processing of superconductor devices, superconducting devices, superconducting/high-conducting conductors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

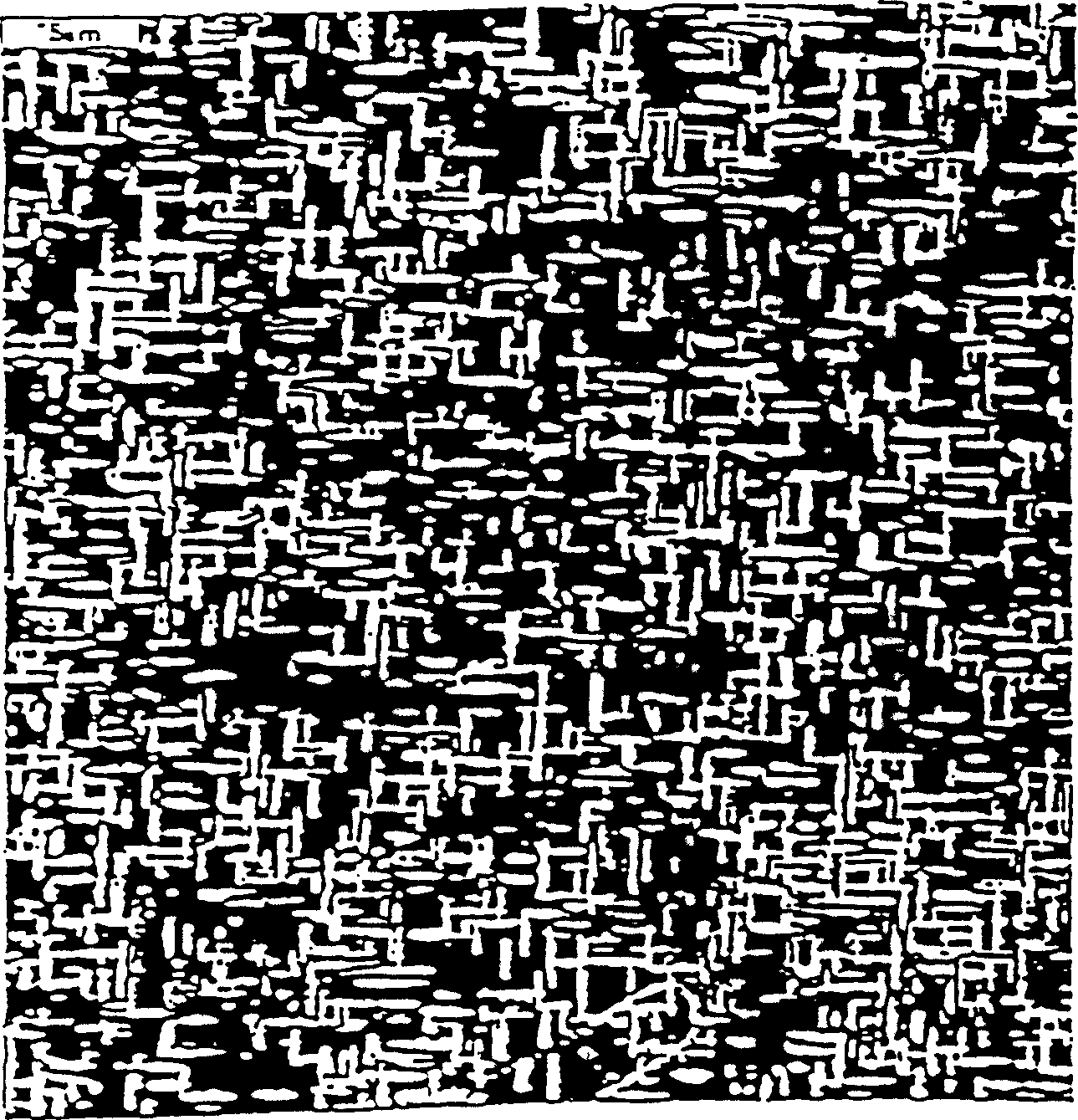

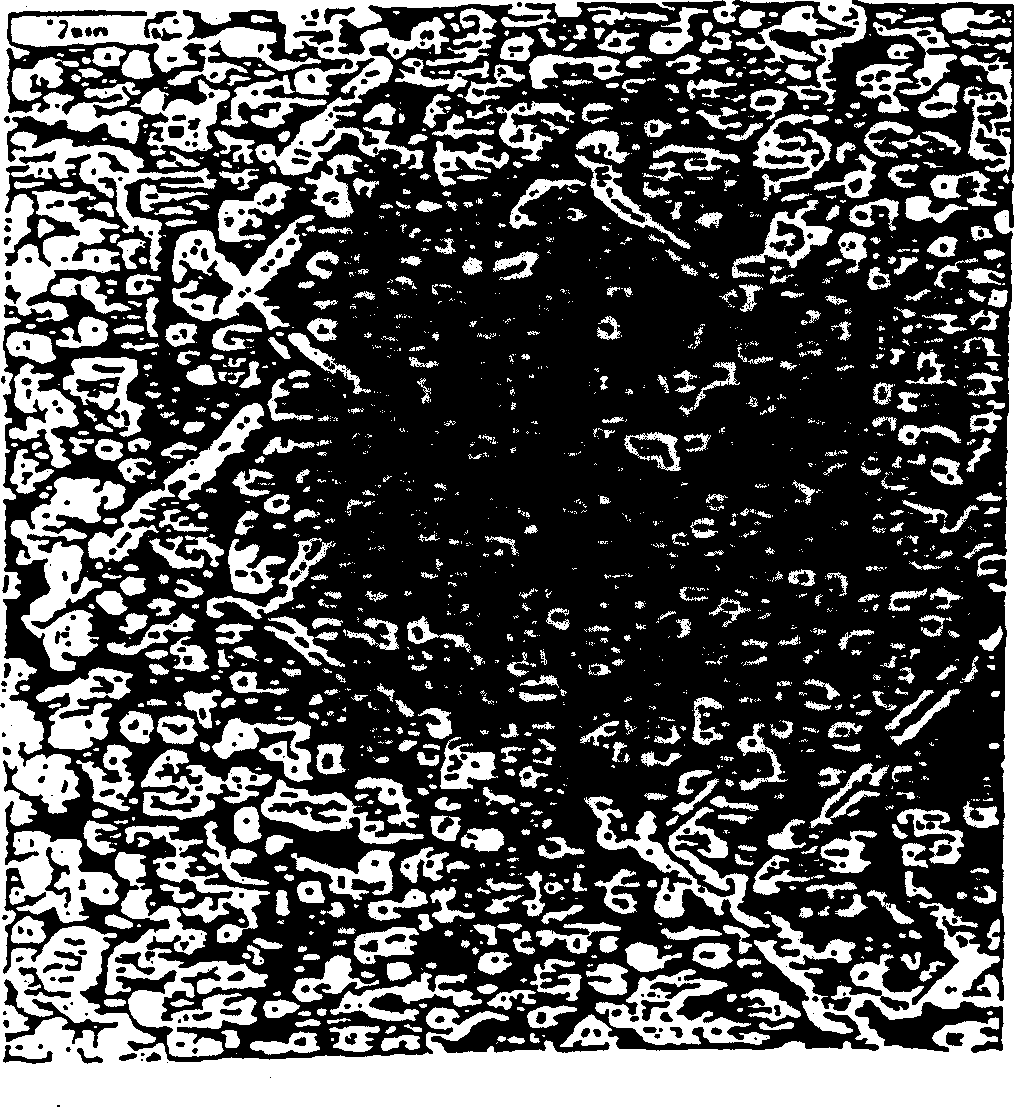

Image

Examples

preparation example Construction

[0094] Said solution for spin coating is prepared by reacting acetate salts of metals (Ba, Y, Cu) and trifluoroacetic acid in water, and drying the obtained product to a semi-solid state (glassy) , and then redissolved the product in methanol. Using the stoichiometric amounts of metal acetate and trifluoroacetic acid, the final solution of the obtained mixed metal trifluoroacetate in methanol was set, wherein the ratio of metals Ba:Y:Cu was 2:1:3.

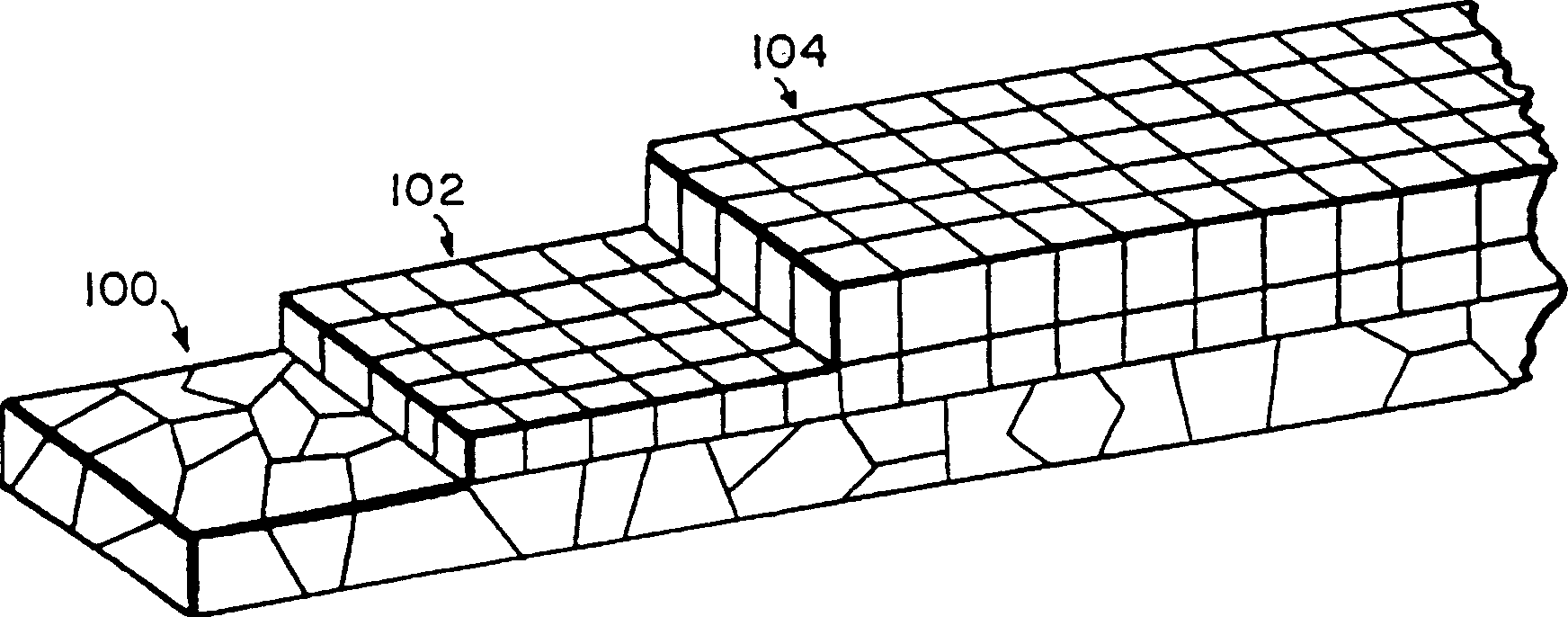

[0095] The larger LaAlO3 single crystal was cut with a diamond wire saw to obtain the substrate. The thickness of the substrate is 0.020 inch and its typical dimensions are about 1 / 4 inch by 1 / 4 inch, although any size substrate can be used, even long wire or ribbon substrates can benefit from the method of the present invention.

[0096] The substrate is chemically and mechanically cleaned prior to spin coating. Ultrasonic cleaning was performed in chloroform, acetone, and methanol, respectively, and then wiped with low-hardness...

Embodiment 1

[0109] This example prepares thicker YBCO oxide superconducting thin films from TFA precursors at relatively low annealing temperatures.

[0110] During this heat treatment (see Figure 10 ), within the first 3 minutes of the initial ramp, 0.01% dry O 2 The mixed gas is injected into the process environment. Due to the time difference between the heating of the furnace equipment and the heating of the heating element of the heating furnace, the temperature of the sample at this moment is still approximately room temperature. Subsequently, the input gas was switched to high humidity (roughly in the range of 95-100% RH at room temperature) 0.01% O 2 mixed composition. During the rest of the warming, the humid low P O2 Ambient gas is passed through the sample and the elevated temperature is maintained until the last 10 minutes of the elevated temperature. The holding temperature was about 700°C (about 10°C fluctuation range, with an initial temperature overshoot of about 10°...

Embodiment 2

[0113] In this example, YBCO oxide superconducting thin films were prepared from TFA precursors by annealing at relatively low humidity. The low-humidity gas is obtained by mixing the high-humidity gas with the dry gas at the very last moment before injection into the processing environment using a manually operated high precision flow meter.

[0114] Sample preparation and furnace equipment were as described in Example 1, with the following changes. At the annealing temperature, from the beginning of the heat treatment until the last 10 minutes, inject low humidity 0.1% O 2 mixed composition. At this point inject dry 0.1% O 2 mixed composition. The humidity of the wet mixed gas used was 1.2% RH at room temperature. The annealing temperature was 785°C (approximately 5°C fluctuation range with essentially no temperature overshoot). The heat treatment of this example is as Figure 11 shown. The critical current density of the treated film is 1.1 × 10 6 A / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com