Circular suspension type semi-dry fume purifier

A flue gas purification and semi-dry technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems such as the inability to be popularized and applied on a large scale, the high price of desulfurization devices, and the inability to build and operate. Achieve the effect of eliminating the phenomenon of scaling and clogging, easy treatment and economical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

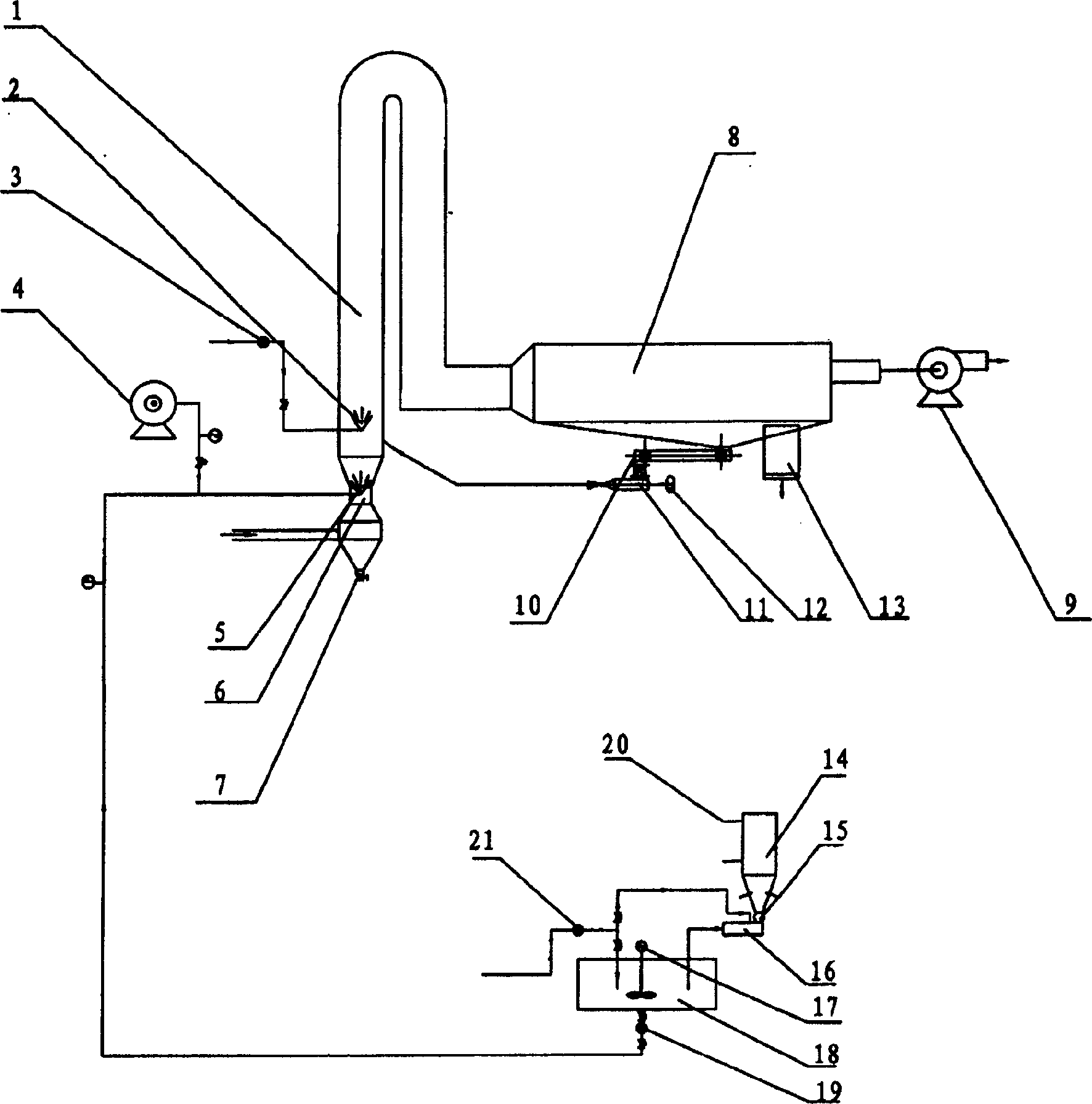

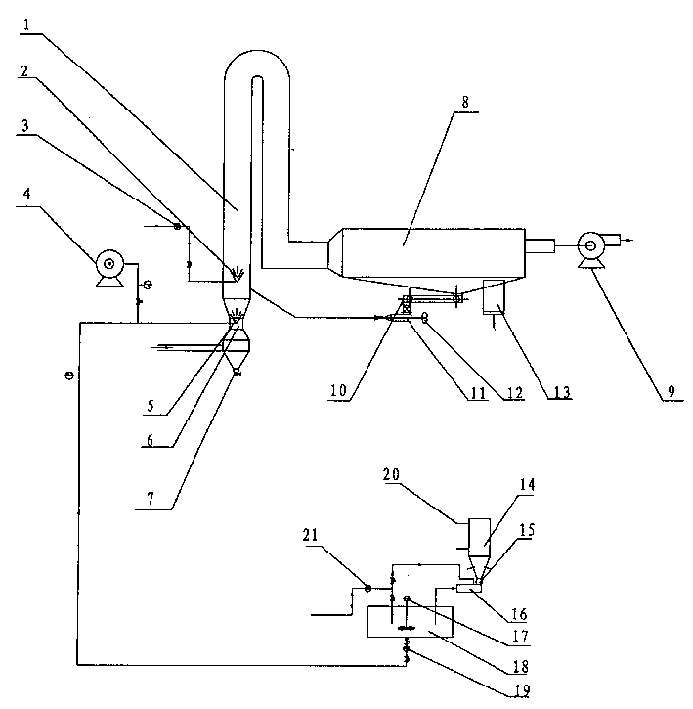

[0018] The circulating suspension semi-dry flue gas purification device has an inverted U-shaped spray drying desulfurization tower 1, and the lower part of one end of the desulfurization tower is equipped with a water two-fluid atomization nozzle 2, a slurry two-fluid atomization nozzle 5, and a Venturi cloth in sequence from top to bottom. Wind device 6, ash valve 7, the other end of the desulfurization tower is connected to one end of the dust collector 8, the other end of the dust collector is connected to the induced draft fan 9, the bottom outlet of the dust collector is connected to one end of the chain conveyor 10, and the other end of the chain conveyor is connected to the fan 12 and feed injection pump 11, and connected with the lower part of the water two-fluid atomizing nozzle at the lower part of the desulfurization tower, the bottom of the dust collector is also provided with a waste discharge port 13, and the water two-fluid atomizing nozzle is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com