Prepn of Li and Mn doped composite oxide positive pole material

A technology for composite oxides and positive electrode materials, applied in lithium oxide;/hydroxide, electrode manufacturing, battery electrodes, etc., can solve problems such as high reaction temperature, low synthesis efficiency, uneven product particle size, etc., and achieve reproducible Good performance, stable performance, improved electrochemical performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

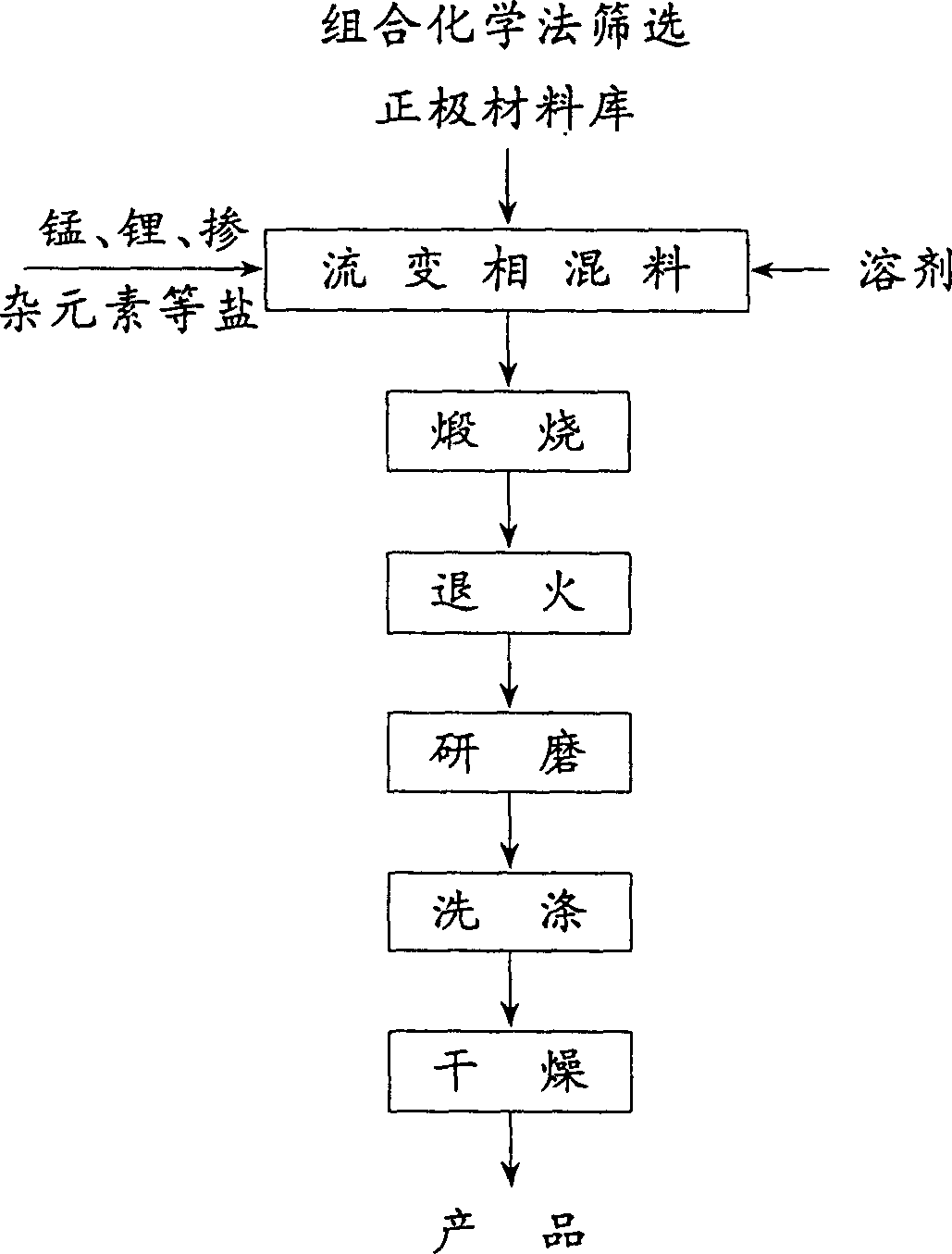

Method used

Image

Examples

Embodiment Construction

[0026] After weighing analytically pure lithium nitrate, electrolytic manganese dioxide treated with 50mol / L nitric acid, and analytically pure impurity salts according to the atomic ratio Li / Mn / M=0.5:0.90:0.10, add a certain amount of alcohol solution , mixed and ground into a paste, and dried at 120°C; then the temperature was raised to 300°C and kept for 10 hours; then the temperature was raised to 450°C and kept for 12 hours; finally, the temperature was raised to 150°C / min Calcined at 720°C for 45 hours; the obtained product was ground, soaked, filtered, washed, dried, and then ground again to finally obtain a black powder positive electrode material. The physical properties of the obtained cathode material: density 3.96g cm -3 , average particle size 9μm, specific surface area 3.5m 2 , the crystal form is spinel.

[0027] The battery made of the above-mentioned positive electrode material, the positive electrode is mixed with 80-85% positive electrode powder, 10-15% ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com