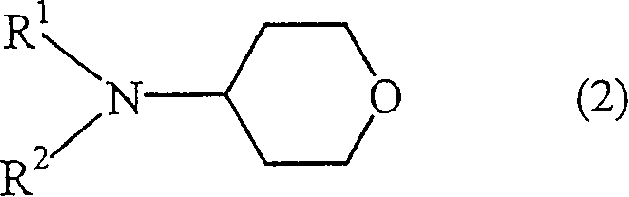

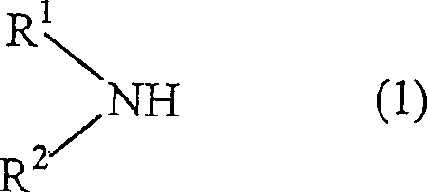

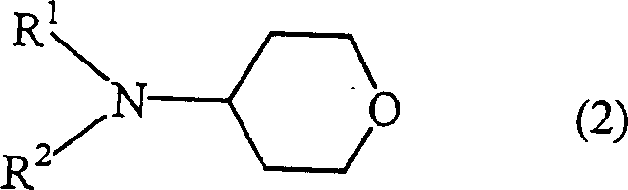

Processes for producing tetrahydropyranyl-4 sulfonate and 4-amino tetrapyran compound

A technology of aminotetrahydropyran compound and tetrahydropyranyl, which is applied in the field of producing 4-aminotetrahydropyran compound and producing tetrahydropyranyl-4-sulfonate, and can solve the problem of tetrahydropyran compound Problems such as low yield, low yield, and difficult synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1.00 g (13.9 mmol) of 3-buten-1-ol and 1.35 g (16.6 mmol) of 37% by weight aqueous formaldehyde (from Wako Junyaku Co. obtained), under a nitrogen atmosphere, 2.66 g (27.7 mmol) of methanesulfonic acid was added dropwise with stirring, and the resulting mixture was reacted at 25° C. for 3 hours. When the reaction was completed, the resulting reaction mixture was analyzed by high-performance liquid chromatography, and it was found that 1.65 g (yield: 66%) of tetrahydropyranyl-4-methanesulfonate had been formed.

Embodiment 2

[0050] In a reaction apparatus similar to Example 1, 1.00 g (13.9 mmol) of 3-buten-1-ol, 0.50 g (15.3 mmol) of 92% by weight paraformaldehyde (obtained from Mitsui Toatsu Chemical Co.) and 5ml of toluene, under a nitrogen atmosphere, 3.99g (41.5mmol) of methanesulfonic acid was added dropwise with stirring, and the resulting mixture was reacted at 25°C for 3 hours. When the reaction was completed, the resulting reaction mixture was analyzed by high-performance liquid chromatography to find that 2.15 g (yield: 86%) of tetrahydropyranyl-4-methanesulfonate had been formed.

Embodiment 3

[0052] Add 1.00g (13.9mmol) 3-buten-1-ol, 0.50g (5.6mmol, calculated as formaldehyde, it is equivalent to 16.8mmol) trioxane and 5ml Toluene, under a nitrogen atmosphere, 2.66 g (27.7 mmol) of methanesulfonic acid was added dropwise with stirring, and the resulting mixture was reacted at 25° C. for 3 hours. When the reaction was completed, the resulting reaction mixture was analyzed by high performance liquid chromatography to find that 2.13 g (yield: 85%) of tetrahydropyranyl-4-methanesulfonate had been produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com