Non-tempered superhigh carbon steel production

A technology of ultra-high carbon steel and production process, applied in the field of production technology of non-quenched and tempered ultra-high carbon steel, can solve problems such as high cost, and achieve the effect of good ductility and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

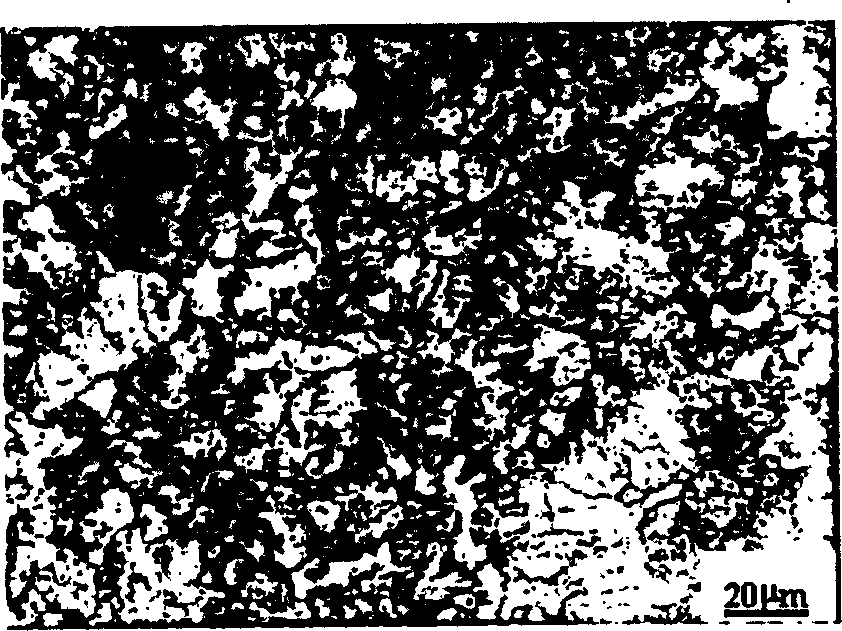

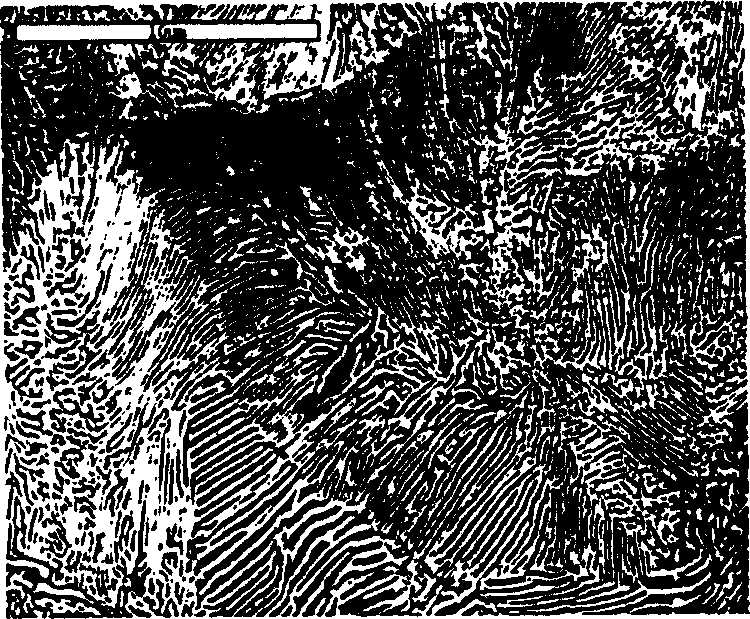

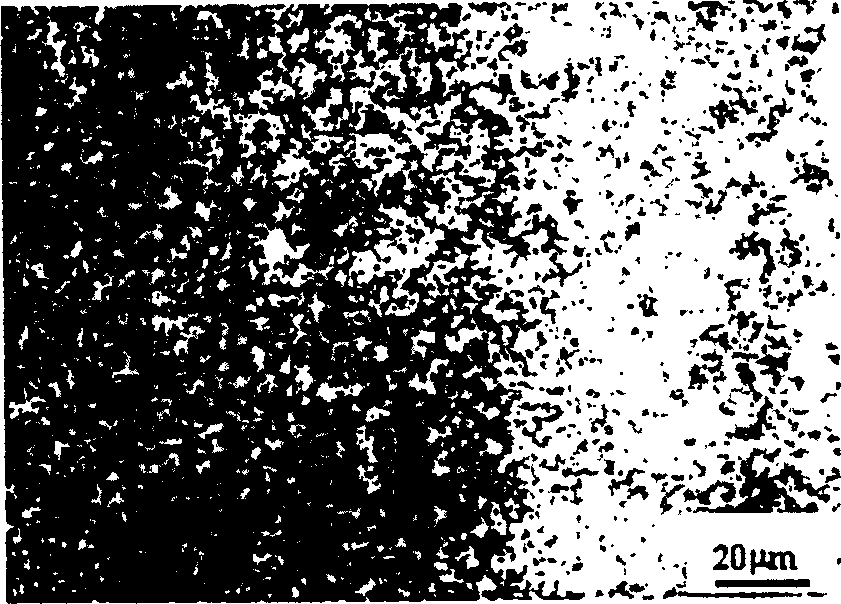

Image

Examples

Embodiment 1

[0061] (1) Alloy composition (chemical analysis results):

[0062] See Table 2;

[0063] (2) Spray forming process

[0064] The specific parameters of the spray forming process: Put the master alloy material into the crucible to melt, the superheat of the melt is about 150°C; the inner diameter of the catheter is 4mm; the pressure of the atomizing gas (nitrogen) is 2.2MPa, the atomization The distance between the device and the substrate is 360mm, the rotation speed of the substrate is 10rpm; the gas / melt flow ratio (G / M) is about 0.30M 3 / kg.

[0065] (3) Isothermal forging

[0066] The billet is taken out after being heated to 850°C for 30 minutes in the furnace; then put into the flat mold of the isothermal forging press that has reached the heat balance of 850°C; after reaching the heat balance again (about 2 minutes), carry out isothermal forging and press 80 tons, which remains unchanged throughout the isothermal forging process; the initial pressure is 185MPa per sq...

Embodiment 2

[0068] (1) Alloy composition (chemical analysis results)

[0069] See Table 2;

[0070] (2) Spray forming process

[0071] Concrete parameters of spray forming process: with embodiment 1

[0072] (3) Isothermal forging

[0073] The billet is taken out after being heated to 870°C for 30 minutes in the furnace; then put into the flat mold of the isothermal forging press that has reached the heat balance of 870°C; after reaching the heat balance again (about 2 minutes), carry out isothermal forging and press 80 tons, which remains unchanged throughout the isothermal forging process; the initial pressure is 200MPa per square centimeter (calculated according to the force-bearing area of the blank), and the strain rate at the initial compression is 6 to 8×10 -3 / S. As the amount of deformation increases, the force area increases, the pressure decreases, and the rate becomes slower. Press from 24mm to 7mm in 15 minutes, the total deformation is 71%, stop forging, the blank is ...

Embodiment 3

[0075] (1) Alloy composition (chemical analysis results)

[0076] See Table 2;

[0077] (2) Injection forming

[0078] Concrete process is with embodiment 1;

[0079] (3) Isothermal forging

[0080] The billet is taken out after being heated to 830°C for 30 minutes in the furnace, and then put into the flat mold of the isothermal forging press that has reached the heat balance of 830°C. After reaching the heat balance again (about 2 minutes), carry out isothermal forging and press 96 tons remain unchanged throughout the isothermal forging process, the initial pressure is 210MPa per square centimeter (calculated according to the force-bearing area of the billet), and the strain rate at the initial compression is 6 to 8×10 -3 / S. As the amount of deformation increases, the force area increases, the pressure decreases, and the rate becomes slower. Press from 23mm to 7mm in 15 minutes, the total deformation is 69%; stop forging, the blank is taken out and air-cooled.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com