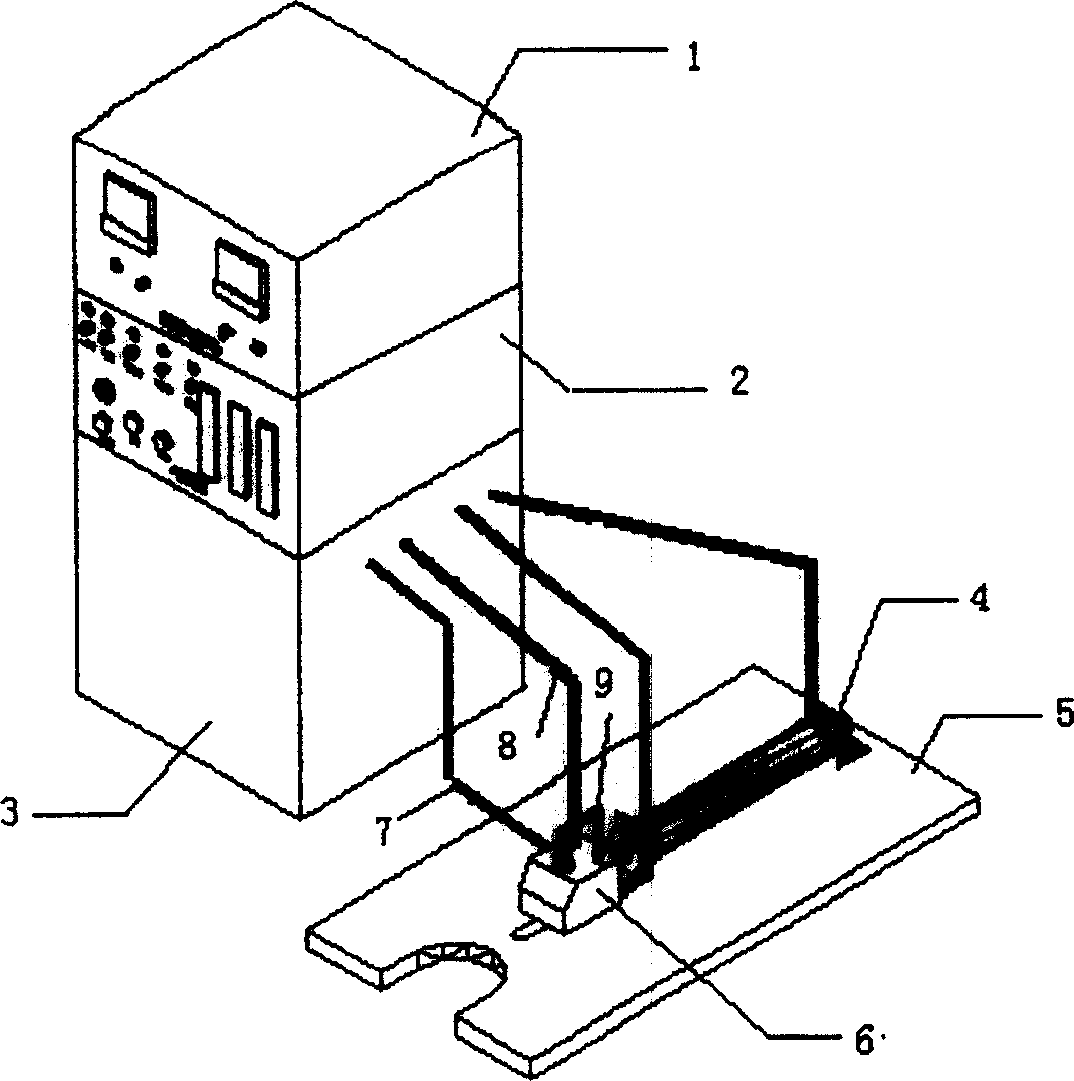

Powder metallurgy static mould wall lubricating device

A mold wall lubrication and powder metallurgy technology, applied in the field of powder metallurgy, can solve the problems of use, high cost, limited selection of lubricating powder, etc., and achieve the effect of great flexibility and easier maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

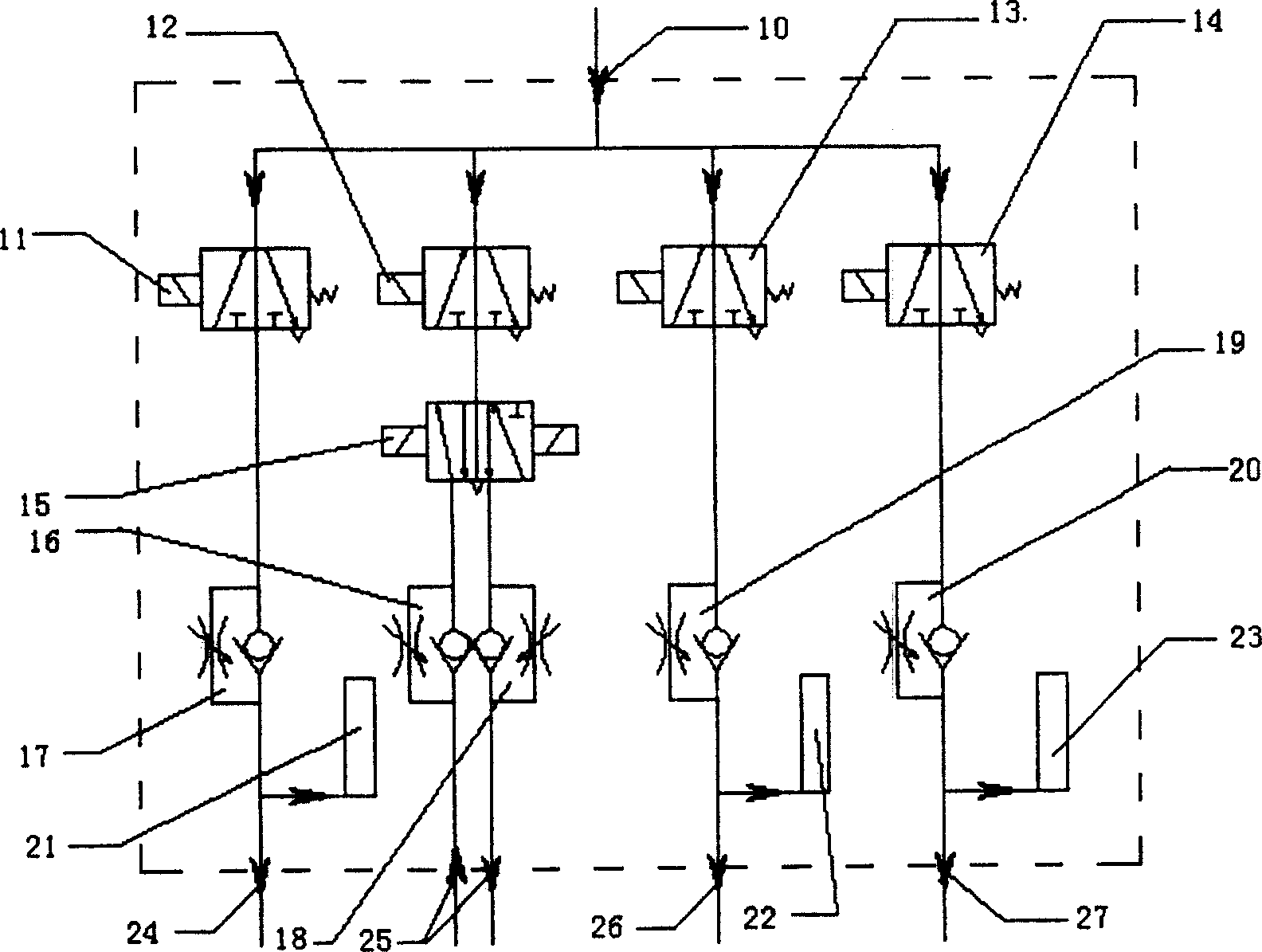

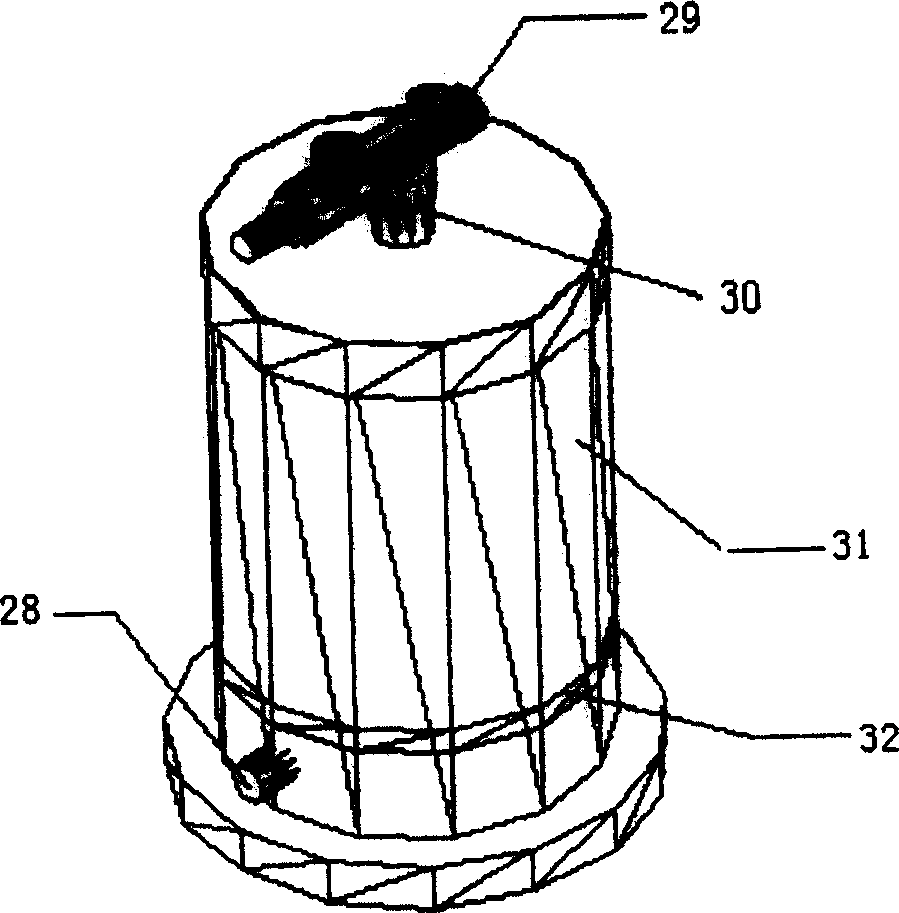

Method used

Image

Examples

example 1

[0046] Example 1: Determination of the required amount of charge that the new electrostatic mold wall lubrication device can bring to each lubricating powder by means of corona discharge. Set the device with a voltage of 12KV as an example, each spraying time does not exceed 1 second, the powder spraying wind pressure is about 0.6MPa, and the length of the powder delivery hose is 1m. Use an electronic analytical balance (accuracy: 0.0001g) to measure the mass of the lubricating powder, and calculate the charge-to-mass ratio of the lubricating powder. The results are shown in the table below:

[0047]

lubricant powder

EBS wax

w-special

the wax

compound run

powder one

compound run

slippery powder two

compound run

slip powder three

compound run

Slippery powder four

compound run

Slippery five

charge to mass ratio

(μc / g)

0.166

...

example 2

[0050] Example 2: Spray lubricating powder on the inner wall of the mold with this new type of electrostatic mold wall lubrication equipment, and press 316L stainless steel powder (fineness: ≤74μm) by using external lubrication or a combination of internal and external lubrication under room / temperature pressure. At 680MPa, measure the green compact density with the micrometer method. The results of each experiment are shown in the table below:

[0051] to lubricate

Way

Internal lubrication

0.2% W-special wax

0.2% EBS wax

none

External lubrication

Compound lubricant powder six

Compound Lubricating Powder II

EBS wax

EBS wax

EBS wax

Pressed powder heating temperature

(℃)

120

120

120

120

120

120

120

110

mold heating temperature

(℃)

1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com