Zeolite deiodination adsorbent with high silver carrying amount and its prepn process

An adsorbent, zeolite technology, applied in chemical instruments and methods, other chemical processes, silicates, etc., can solve the problems of reduced total iodine content, no description, and high price, and achieves simple methods, mild preparation conditions, and reduced costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] STI mineral raw powder is exchanged and modified according to the following steps:

[0043] 1. Add the original STI powder to 1.0mol / L ammonium chloride solution, the solid-to-liquid ratio is 1:10, heat to 95-103°C and reflux for 2 hours, exchange four times, wash and dry with water.

[0044] 2. The ammonium chloride-exchanged STI powder is roasted at 500°C for 3 hours to convert it into a hydrogen-type zeolite.

[0045] 3. Add the calcined hydrogen-type zeolite to 0.5mol / L acetic acid with a solid-to-liquid ratio of 1:10, heat to 95-100°C and reflux for 2 hours, wash and dry with water. Obtain H-STI-I samples.

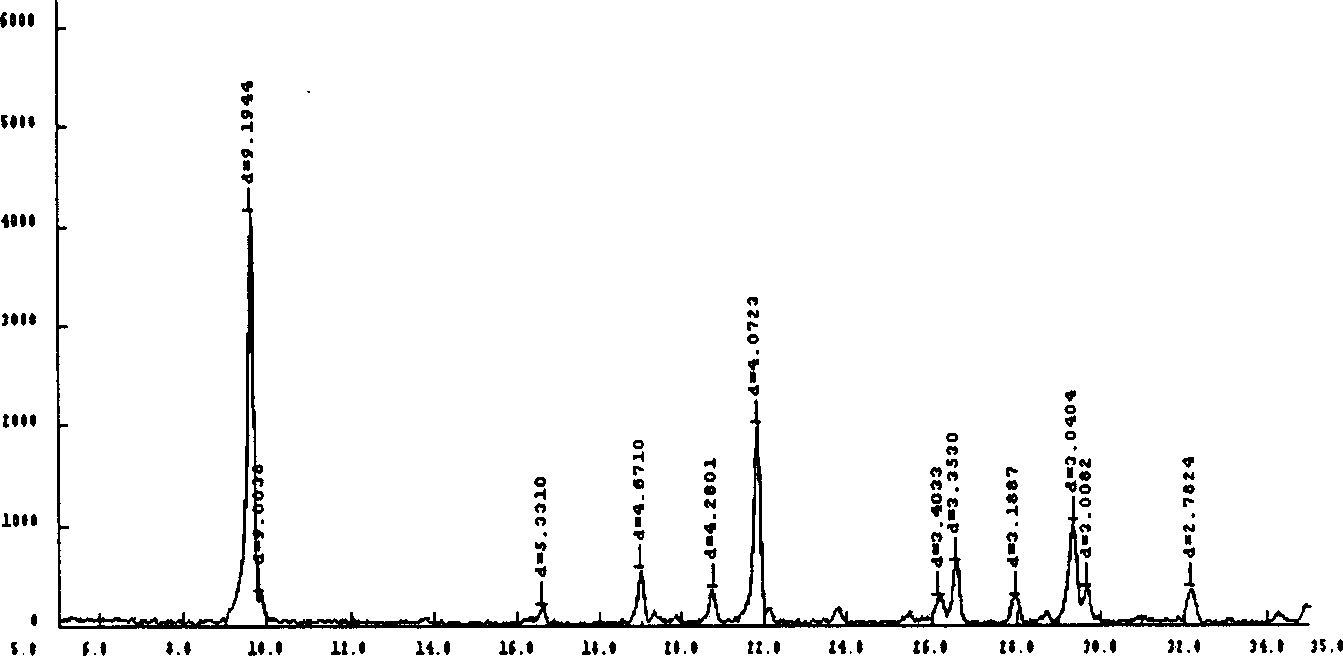

[0046] STI zeolite was exchanged with ammonium chloride, calcined at 500°C for 3 hours, and then treated with acetic acid, its structure remained stable. XRD spectrum see figure 2 (Online is before processing).

Embodiment 2

[0048] STI raw powder is modified according to the following steps

[0049] 1. Add STI raw powder into 1.5mol / L ammonium nitrate solution, the solid-to-liquid ratio is 1:15, heat to 105-115°C and reflux for 5 hours, exchange four times, wash and dry.

[0050] 2. Add the ammonium-exchanged STI to 1.0mol / L acetic acid, the solid-to-liquid ratio is 1:10, heat to 80-90°C and reflux for 1 hour, exchange twice, wash and dry with water. That is, H-STI-II was obtained.

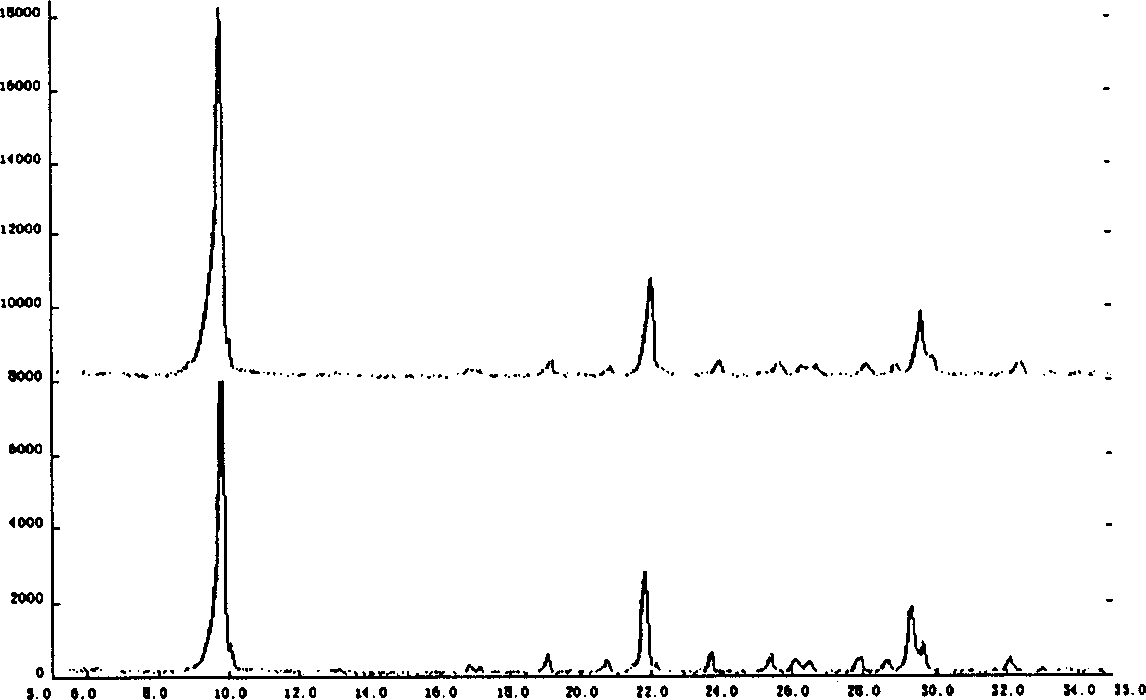

[0051] Apparently after being treated with ammonium nitrate and then treated with acetic acid, the obtained H-STI-II still has high crystallinity and structural stability. The powder XRD spectrum of H-STI-II calcined at different temperatures is shown in image 3 . From top to bottom are the sample powder XRD spectra of uncalcined H-STI-II, calcined at 300°C for 4 hours, and calcined at 500°C for 1.0 hour.

Embodiment 3

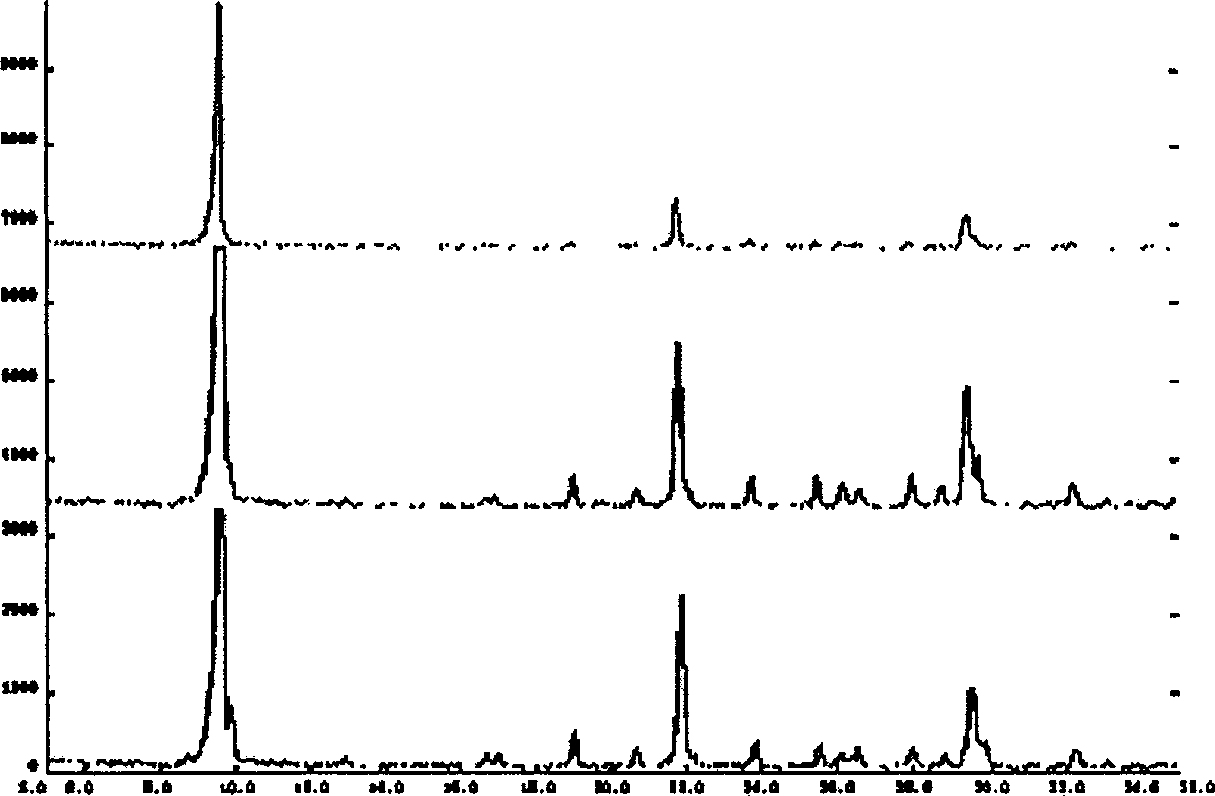

[0053] H-STI-I powder uses 0.05 mol / l silver nitrate as the exchange liquid, liquid / solid = 15 / 1, carries out silver ion exchange under the condition of stirring at room temperature for 12 hours. After the sample was filtered, washed, and dried, it was analyzed by EDX to have a silver content of 5.6%. The powder XRD spectrum of the obtained Ag-STI is shown in Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com