Process for preparing creep-resistant atactic polypropylene copolymer

A technology of random polypropylene and copolymer, applied in the field of preparation of random polypropylene copolymer material, can solve the problems of diffusion of comonomer, complicated difficulty, sticking to kettle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

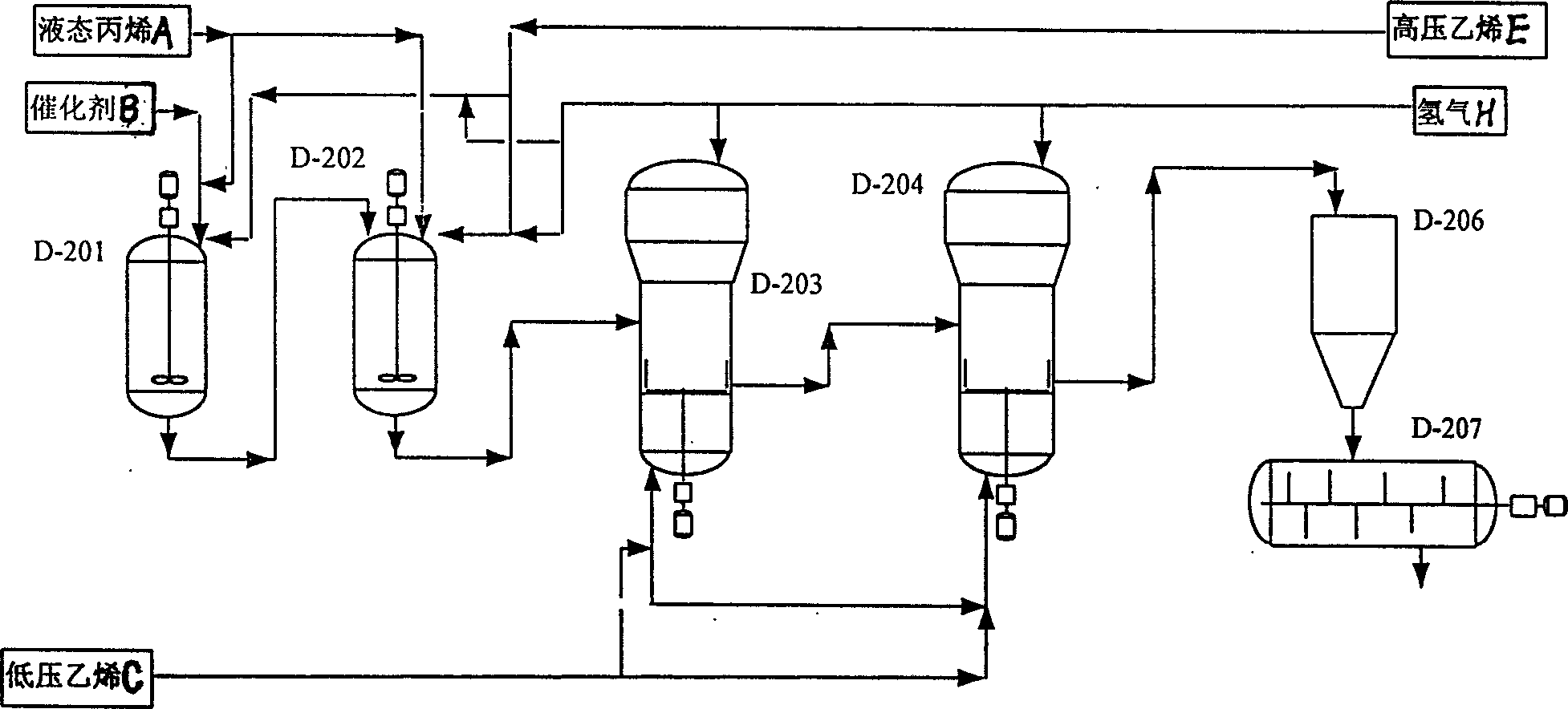

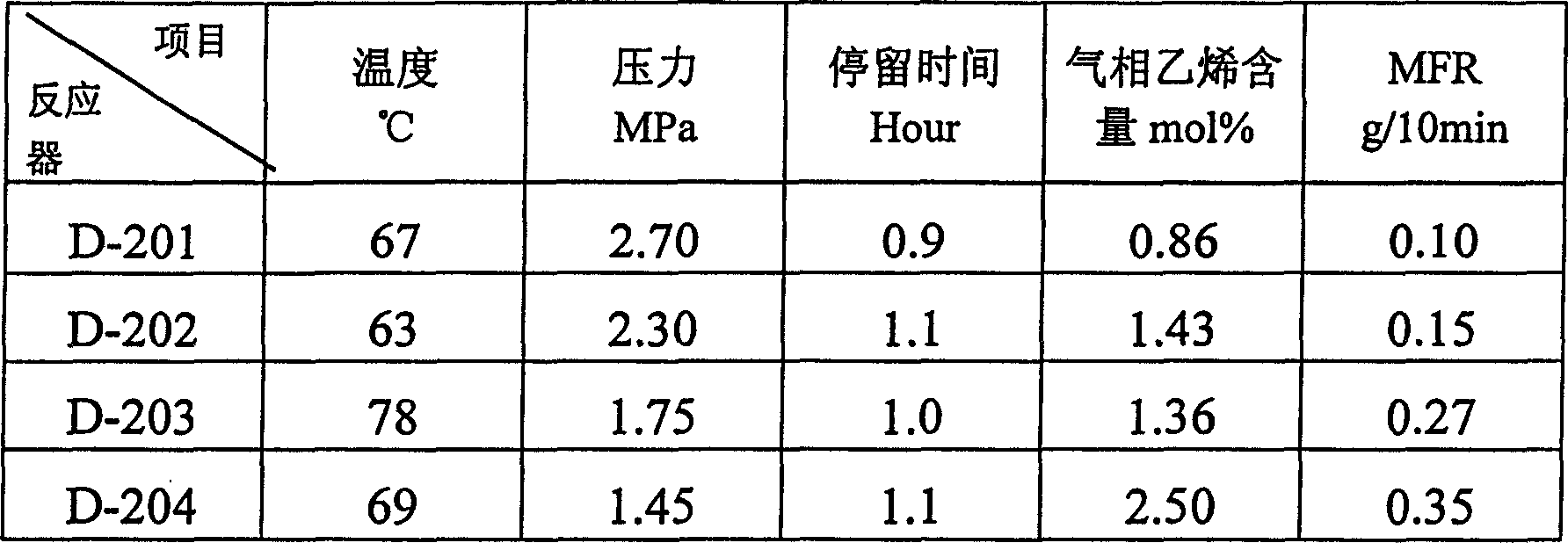

[0016] The main catalyst is pre-polymerized, and then enters the first liquid phase reactor D-201 to contact with propylene to carry out liquid phase polymerization reaction. A small amount of hydrogen is introduced to control the melt flow rate (MFR) of the polymer, and an appropriate amount of ethylene is introduced to carry out Copolymerization reaction; then the reactants in the first liquid phase reactor D-201 continuously enter the second liquid phase reactor D-202, continue the copolymerization reaction under the action of hydrogen, propylene, and ethylene, and the formed slurry then enters The first gas phase reactor D-203, where it carries out gas phase copolymerization reaction with gas phase propylene, hydrogen, and ethylene, and then enters the second gas phase reactor D-204 for gas phase copolymerization reaction with gas phase propylene, hydrogen, and ethylene, and then enters separator D -206 dryer D-207 separates and dries to form the final product polypropylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com