Cathode ray tube comprising cathode of composite material

A cathode ray tube, cathode metal technology, applied in the direction of cathode ray tube/electron beam tube, discharge tube solid thermionic cathode, discharge tube, etc., can solve problems such as instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

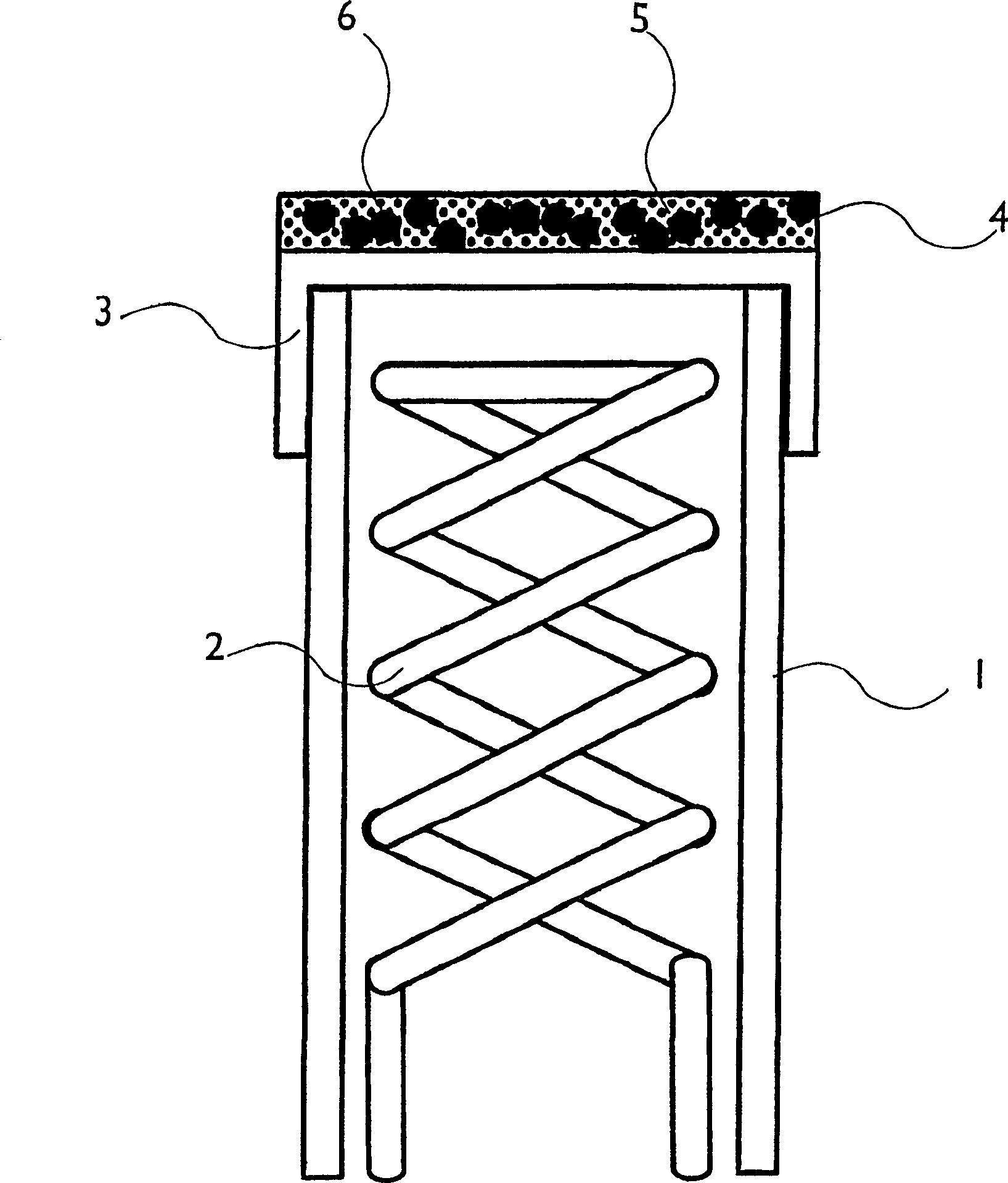

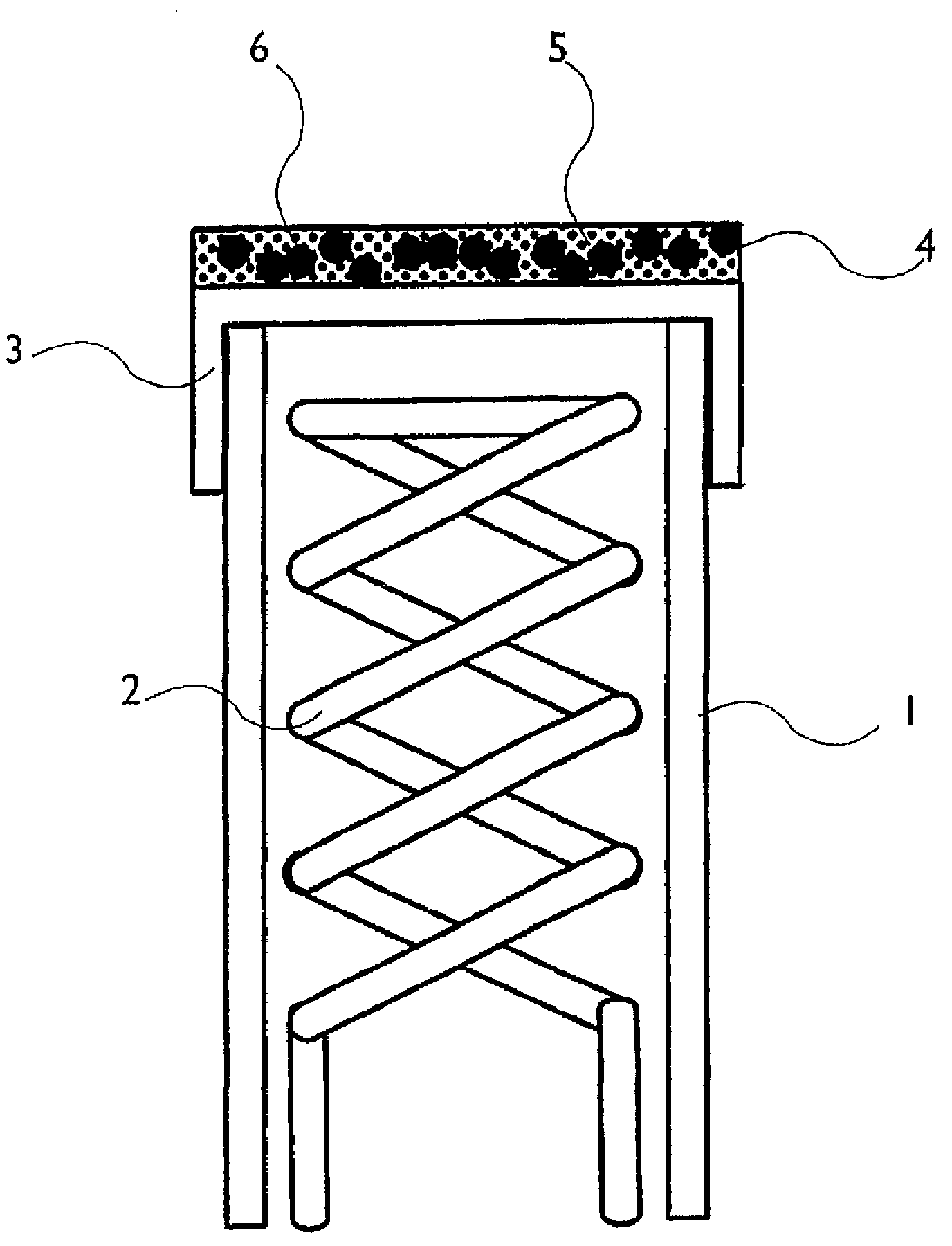

[0050] Such as figure 1 As shown, the oxide cathode in the cathode ray tube according to the first embodiment of the present invention has a hat-shaped cathode substrate composed of nickel and an alloy of 0.03 wt % Mg, 0.02 wt % Al, 1.0 wt % W. The cathode base is located on top of the cylindrical cathode carrier (sleeve), where the heater is installed.

[0051] On top of the cathode substrate there is a cathode coating. To form the cathode coating, the cathode substrate was first cleaned, then a mixture of 3.0% by weight scandium oxide powder and 97% by weight oxide starting compound powder was suspended in a solution of ethanol, butyl acetate and nitrocellulose. Scandium oxide powder has a long granular structure with an average particle size of 3±2 μm. The oxide starting compound powder consisted of co-precipitated barium-strontium-calcium-carbonate in a weight ratio of 22:12:1, and 150 ppm scandium oxide.

[0052] The suspension is sprayed onto the cathode substrate. T...

Embodiment 2

[0055] Such as figure 1 As shown, the cathode in the cathode ray tube according to the second embodiment of the present invention has a cap-shaped cathode substrate composed of nickel and an alloy of 0.1 wt % Mg, 0.06 wt % Al, 2.0 wt % W. The cathode base is located on top of the cylindrical cathode carrier (sleeve), where the heater is mounted. On top of the cathode substrate there is a cathode coating.

[0056] To form the cathode coating, the cathode substrate was first cleaned, then a mixture of 1.50 wt% yttrium oxide powder and 98.5 wt% oxide starting compound powder was suspended in a solution of ethanol, butyl acetate and nitrocellulose. The yttrium oxide powder has a long granular structure with an average particle size of 2 μm. The oxide starting compound powder consisted of co-precipitated barium-strontium-carbonate, and 100 ppm yttrium oxide in a weight ratio of 1:1.

[0057] The suspension is sprayed onto the cathode substrate. The layer thickness is 70 μm. Th...

Embodiment 3

[0060] Such as figure 1 As shown, the cathode in the cathode ray tube according to the third embodiment of the present invention has a cap-shaped cathode substrate composed of nickel and an alloy of 0.05% by weight of Mg, 0.05% by weight of Al and 2.0% by weight of W. The cathode base is located on top of the cylindrical cathode carrier (sleeve), where the heater is installed. On top of the cathode substrate there is a cathode coating.

[0061] To form the cathode coating, the cathode substrate was first cleaned, then a mixture of 1.2 wt% scandium oxide powder and 98.8 wt% oxide starting compound powder was suspended in a solution of ethanol, butyl acetate and nitrocellulose. Scandium oxide powder has a long granular structure with an average particle size of 1.7 μm. The alkaline earth metal oxide starting compound powder consists of co-precipitated barium-strontium-calcium-carbonate in a weight ratio of 1:1, and a particle size of 120 ppm d 50 <0.4μm yttrium oxide composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com