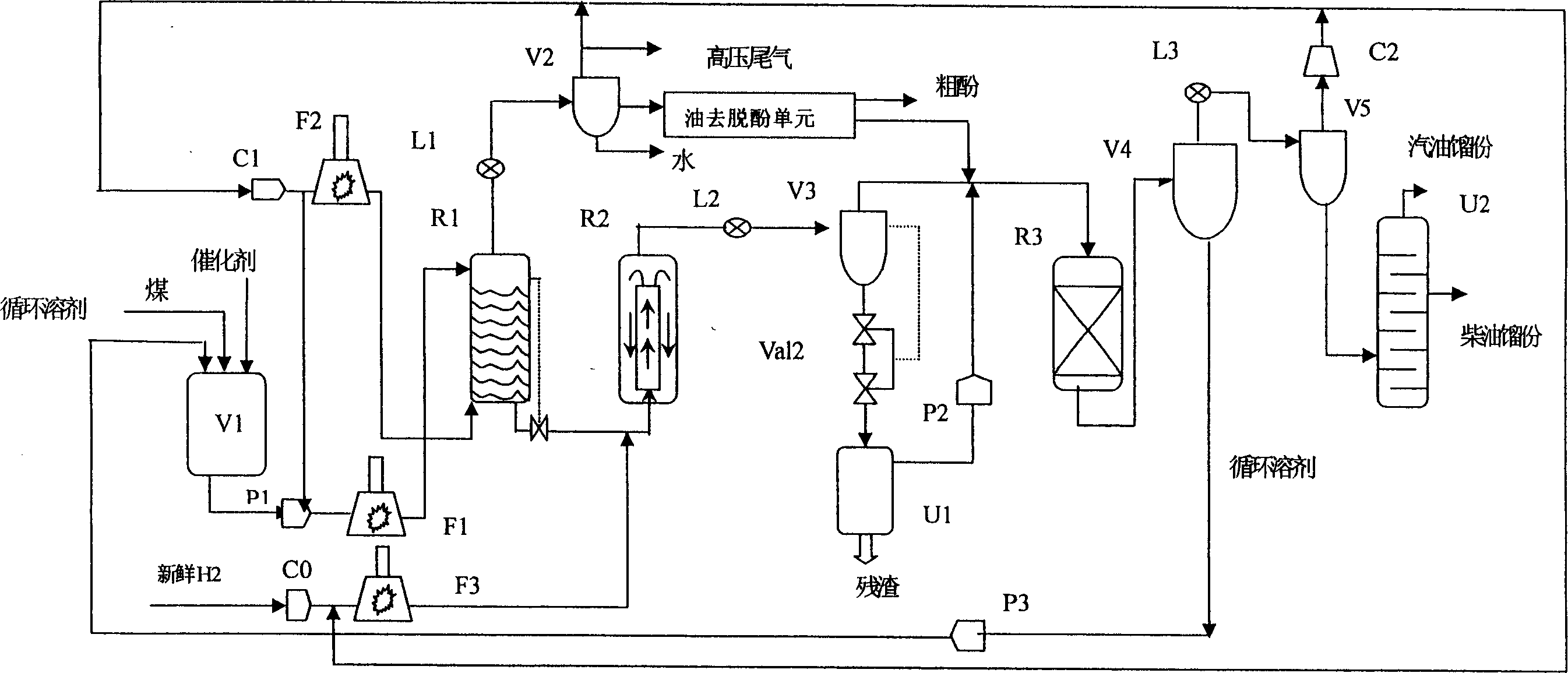

Coal directly-liquifying process with series counter-current and circulating coal-liquifying reactor

A technology of hydrogenation reactor and direct coal liquefaction, applied in the preparation of liquid hydrocarbon mixture, petroleum industry, etc., can solve the problems of long mass transfer rate, long residence time, short residence time, etc. Hydrogen performance and the effect of improving the efficiency of coal liquefaction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: The liquefaction results of a direct coal liquefaction method of a young bituminous coal in the first-stage countercurrent reactor and the second-stage internal circulation loop reactor and online hydrogenation reactor are compared with a Chinese young bituminous coal in two bubbling The liquefaction results of the conventional coal liquefaction process with reactors in series are listed in Table 1.

[0016] R1

Embodiment 2

[0017] Example 2: The liquefaction results of a Chinese lignite direct liquefaction method in which the first-stage countercurrent reactor, the second-stage internal circulation loop reactor and the online hydrogenation reactor are connected in series and the liquefaction results of a Chinese lignite traditional liquefaction process Listed in Table 2.

[0018] R1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com