Process for the preparation of iron blue

A technology of iron blue and formula, applied in the direction of fibrous fillers, etc., can solve problems such as product quality impact, and achieve the effect of simplifying the production process, less equipment, and shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

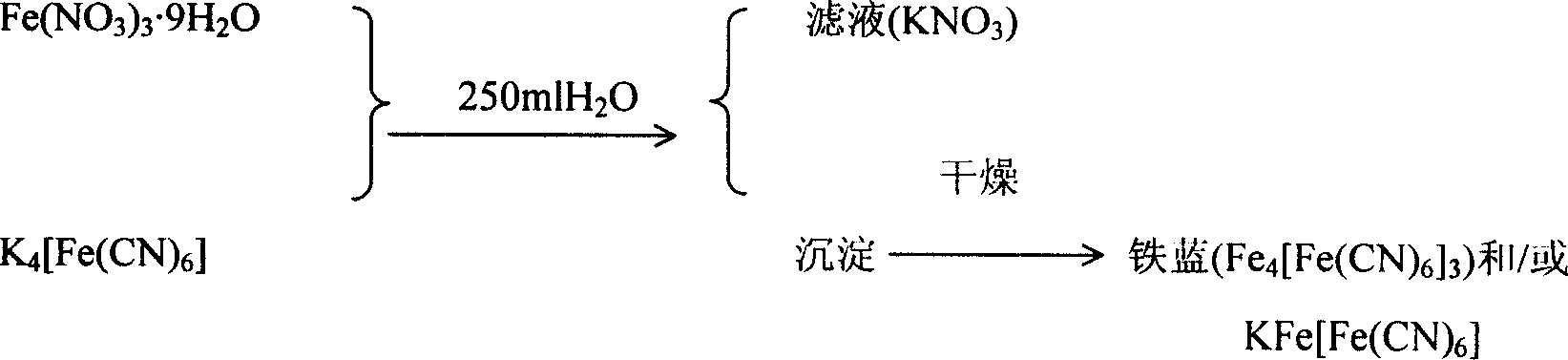

[0022] Example 1: Weigh 4.04g ferric nitrate nonahydrate and 4.22g potassium hexacyanoferrous ferrite trihydrate, mix and grind evenly, then add 250ml distilled water to dissolve, let stand at room temperature for 3 days, filter, discard the filtrate, and remove the precipitate After drying, 2.98 g of iron blue was obtained with a yield of 96.94%. Its technological process is:

[0023]

example 2

[0024] Example 2: Weigh 3.03g ferric nitrate nonahydrate and 4.22g potassium hexacyanoferrous ferrite trihydrate, mix and grind evenly, then add 250ml distilled water to dissolve, leave at room temperature for 2 days, filter, discard the filtrate, and remove the precipitate After drying, 2.34 g of iron blue was obtained with a yield of 93.31%.

example 3

[0025] Example 3: Weigh 4.04g ferric nitrate nonahydrate and 3.16g potassium hexacyanoferrous ferrite trihydrate, mix and grind evenly, then add 250ml distilled water to dissolve, let stand at room temperature for 1 day, filter, discard the filtrate, and remove the resulting precipitate After drying, 2.00 g of iron blue was obtained with a yield of 87.08%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com