Biological denitrification technique for waste water of bean products and fuzzy control device and method

A bean product wastewater and fuzzy control technology, applied in the direction of aerobic and anaerobic process treatment, can solve the problems of excessive aeration or stirring time, incomplete nitrification or denitrification, insufficient aeration or stirring time, etc., to achieve The effect of reducing sludge generation, reducing alkali dosage, and saving oxygen supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

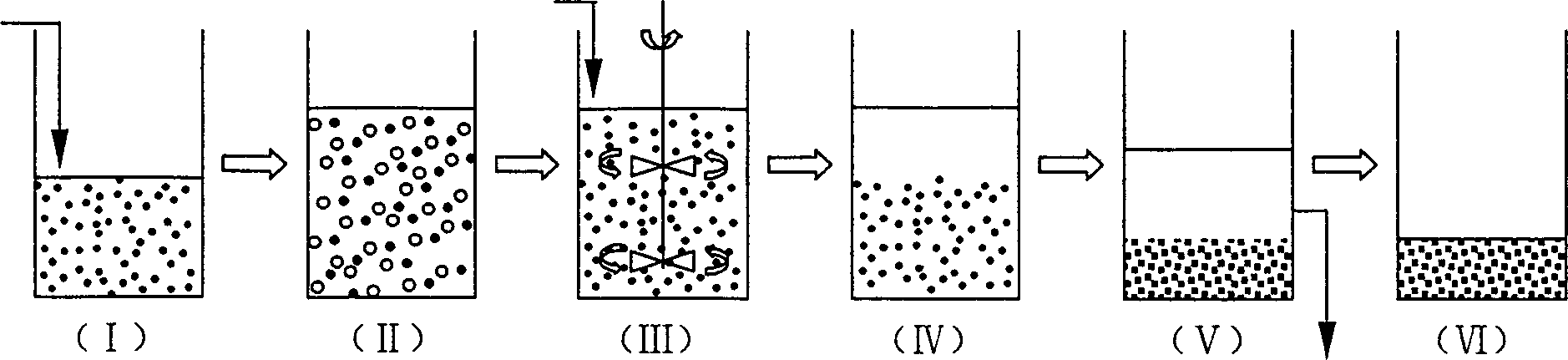

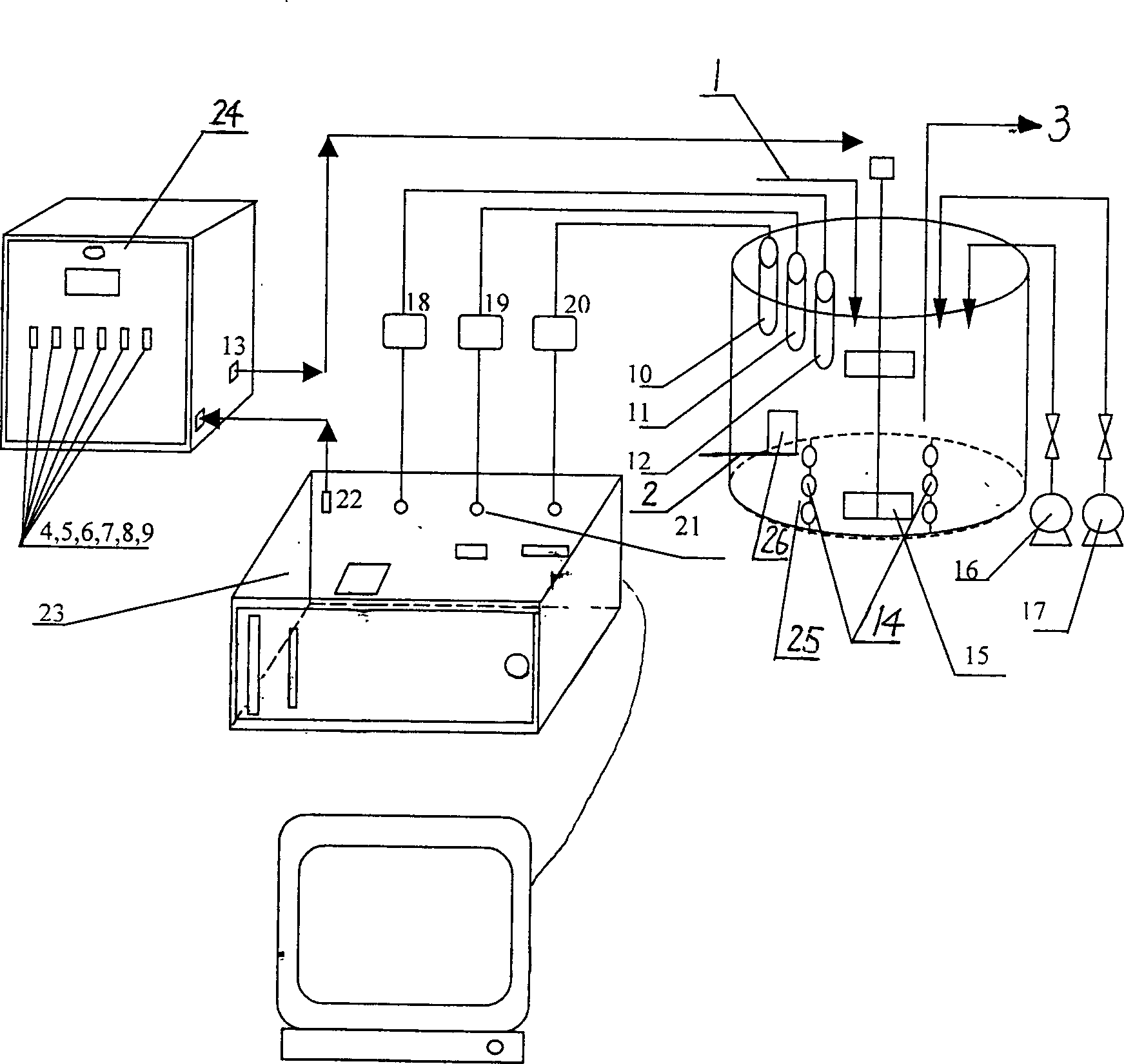

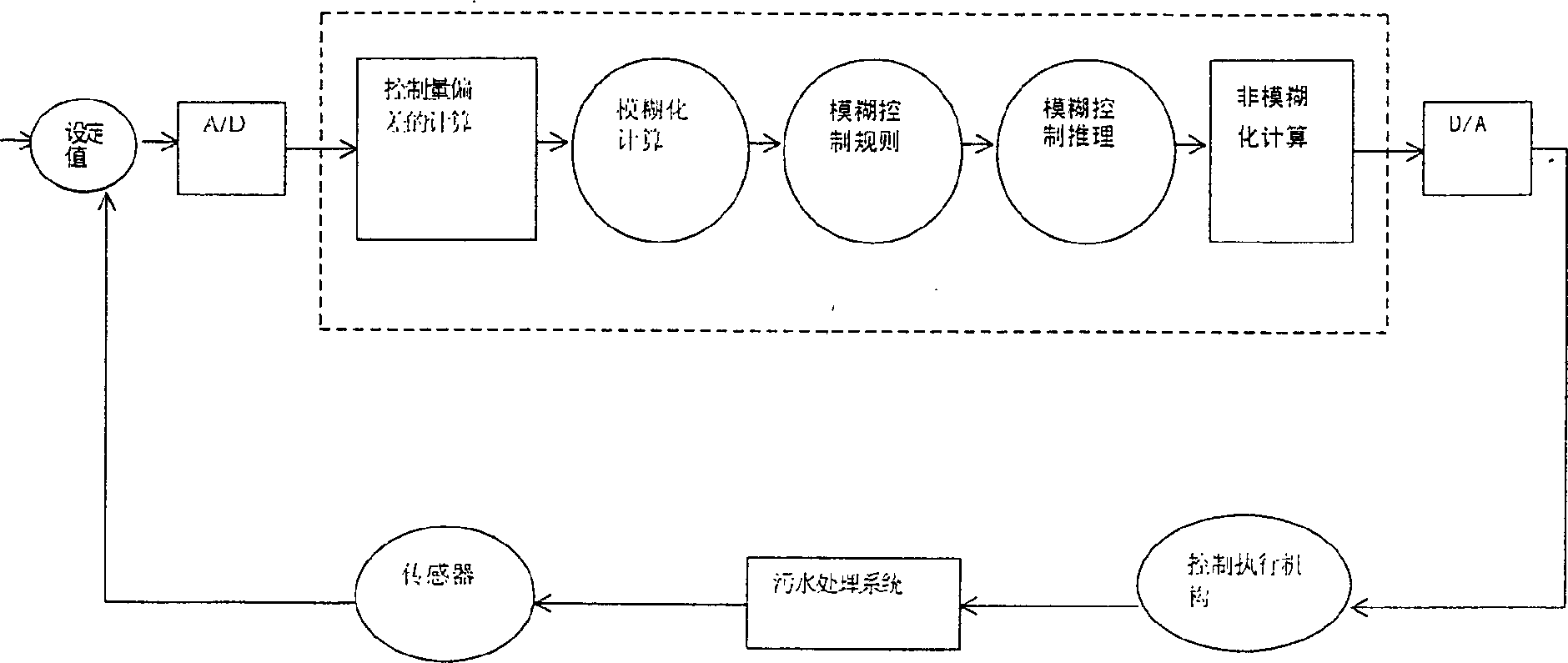

Method used

Image

Examples

Embodiment

[0054] Example: the dilution of the actual soybean product wastewater (pH=4-5, COD=10000-15000mg / L, TN=500-600mg / L) discharged by a food processing enterprise is used as raw water. The selected SBR reaction tank has an effective volume of 38L, and the COD concentration of the mixed solution in the reaction tank is maintained at 400-800mg / L. 4 + -N concentration is 65~75mg / L, and the initial MLSS in the reaction tank is 3-5~4-0g-L -1 , the aeration rate is constant at 0-6m 3 / h, the mud age is maintained at about 50d, and the reaction temperature is 25°C. After implementing fuzzy control, the cumulative rate of nitrite (NO 2 - -N / NO X - -N) is always maintained above 96%, which is a typical short-range nitrification type; the removal rate of COD, ammonia nitrogen and total nitrogen in the final effluent of the reaction tank is always maintained above 90%, 99% and 92%.

[0055] Fuzzy control of aeration time:

[0056] Taking DO as the fuzzy control parameter of the aerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com