Golf ball head with non-fusion clump weight in welding process

A technology for golf club heads and counterweights, which is applied to golf balls, golf clubs, rackets, etc. It can solve the problems of uneven weld bead, affect the appearance, and difficult quality management of golf club heads, so as to avoid melting , improve the appearance of the product, and facilitate the control of the quality of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

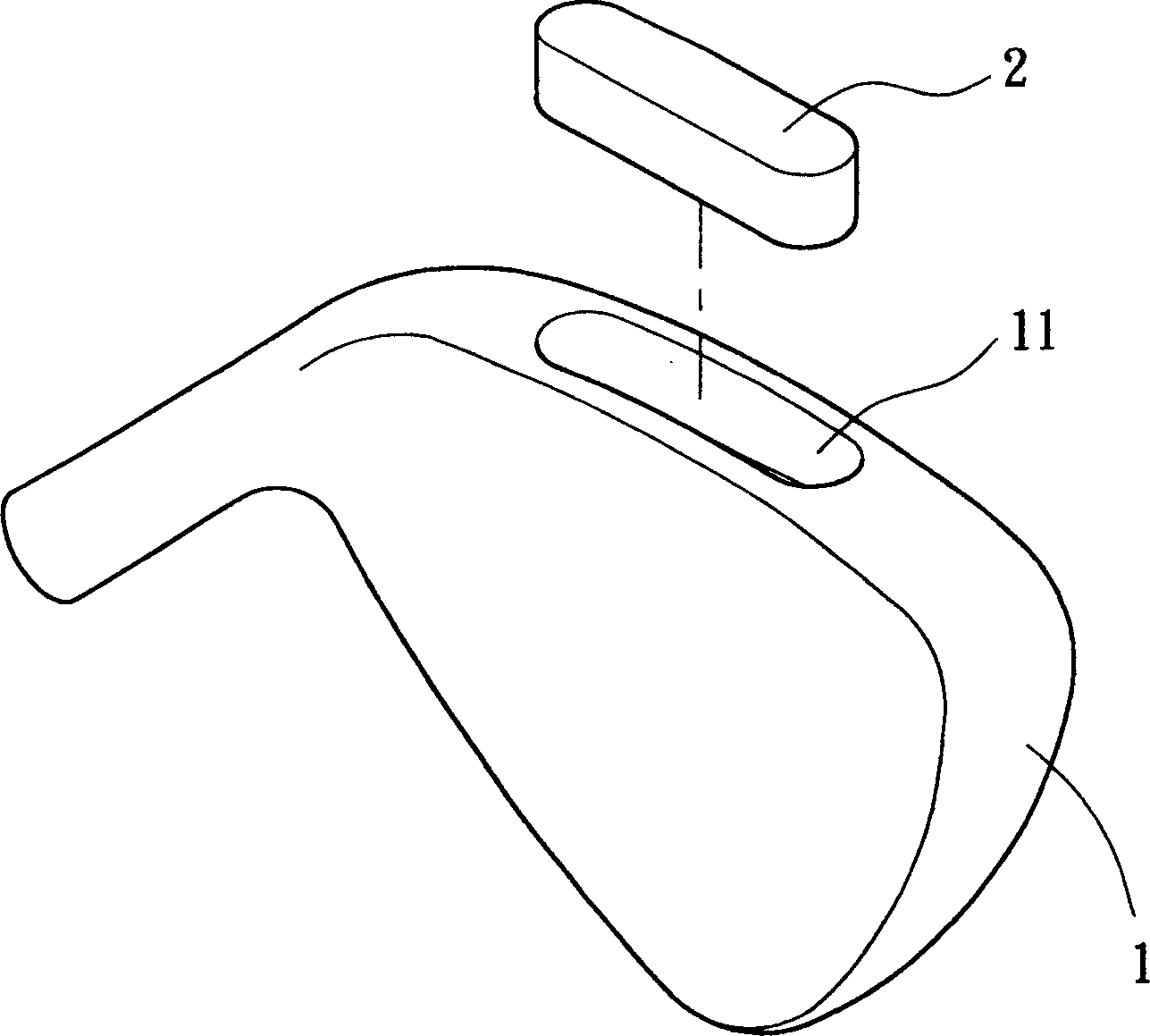

[0039] Such as Picture 9 , Picture 10 As shown, the present invention includes a club head body 5 and a counterweight 6a.

[0040] The head body 5 is provided with an accommodation chamber 51 for accommodating the counterweight 6. It is made of S20C, 8620 or SUS304 material.

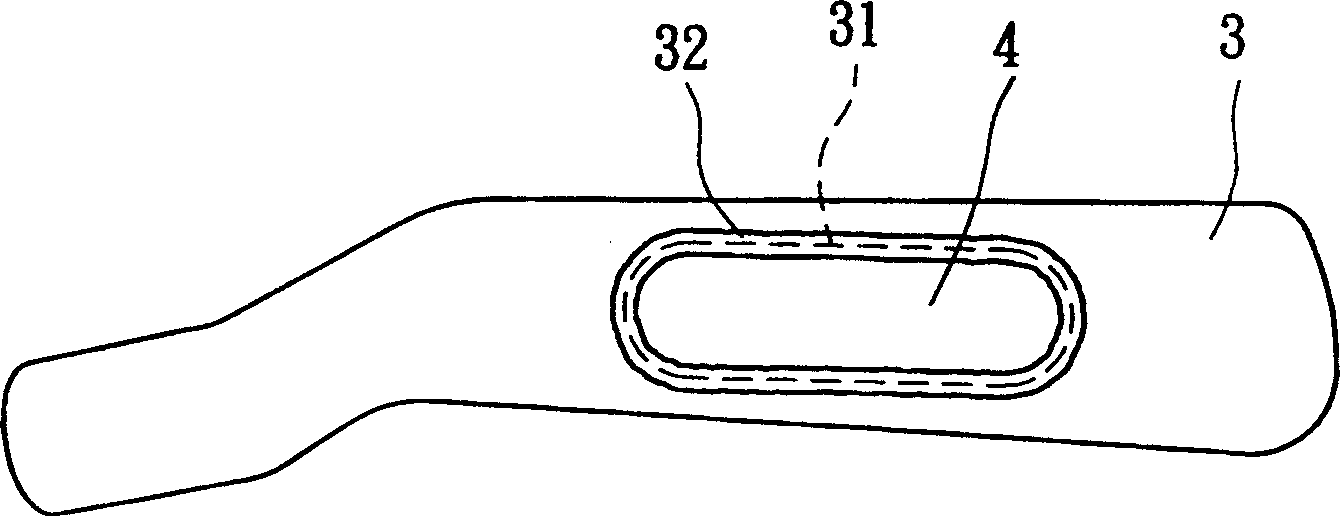

[0041]The weight 6a is provided with a convex portion 61 formed around and connected by an inclined surface 612, which is made of a high melting point material as shown in Table 1, such as tungsten (W), tantalum (Ta), molybdenum (Mo) or niobium (Nb). ), etc. It can also be made of other high melting point materials and a small amount of other metals as alloy materials. Since the melting point of the high melting point metal is too high to be melted by a general high-frequency melting furnace, the weight 6 is preferably manufactured by a powder metallurgy process.

[0042] The counterweight 6 a is accommodated in the chamber 51 of the club head body 5, and a channel is formed between the upper inclined surf...

Embodiment 3

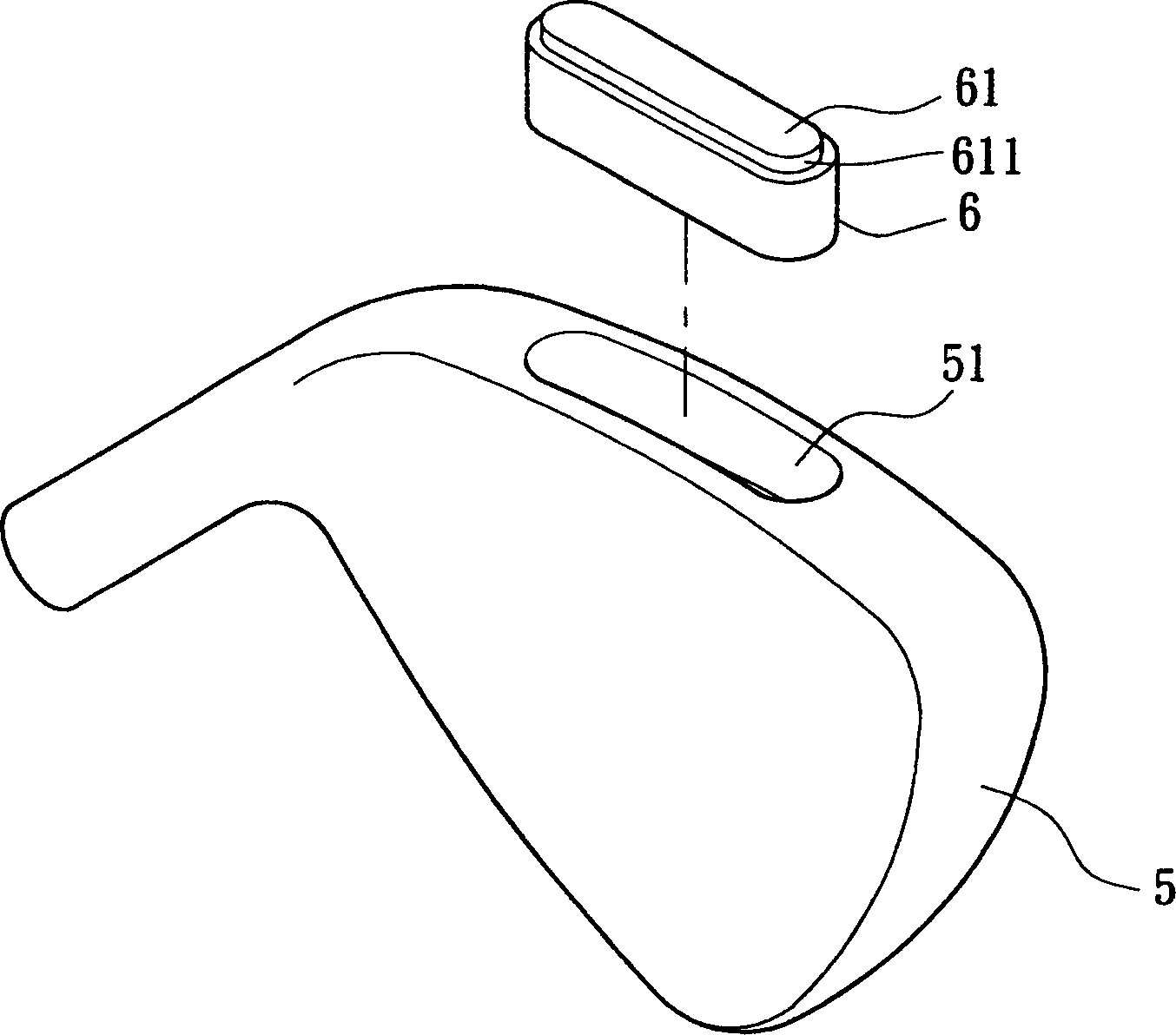

[0044] Such as Picture 10 , Picture 11 As shown, the present invention includes a club head body 5a and a counterweight 6.

[0045] The head body 5a is provided with a chamber 51 for the counterweight 6 to be accommodated and a flange 52 formed on the periphery of the chamber 51, which is made of titanium or titanium alloy, such as 6-4 titanium, or low carbon. Made of steel, low-alloy steel or stainless steel. The flange 52 is integrally formed on the head body 5a to be directly used as solder during the welding process.

[0046] The weight 6 is provided with a convex portion 61 surrounded by a step portion 611, which is made of a high melting point material as shown in Table 1, such as tungsten (w), tantalum (Ta), molybdenum (MO) or niobium (Nb) It can also be made of other high melting point materials and selected a small amount of other metals as alloy materials. Since the melting point of the high melting point metal is too high to be melted by a general high-frequency meltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com