Verticle magnetic recording medium and its manufacturing method and magnetic recording/reproduing device

A technology of perpendicular magnetic recording and media, applied in magnetic recording, data recording, recording information storage, etc., which can solve the problem of signal-to-noise ratio reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0056] The present invention will be described in more detail through examples below.

specific Embodiment approach 1

[0057] Prepare a non-magnetic glass substrate in the shape of a 2.5-inch hard disk.

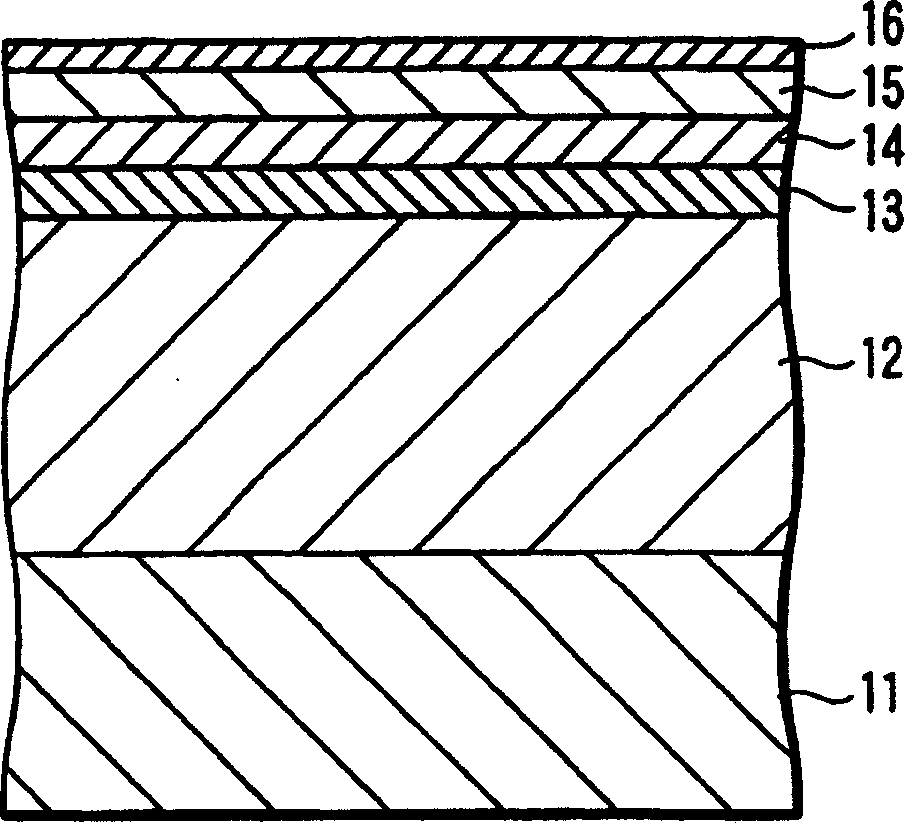

[0058] The vacuum chamber of a sputtering device is evacuated to 2 x 10 -5 Pa or less, in a 0.67-Pa Ar environment by using Co 84 Zr 6 Nb 10 target and Ta target, forming a 200-nm thick Co 84 Zr 6 Nb 10 The soft magnetic layer and the 8-nm thick Ta layer serve as a soft magnetic layer and a first underlayer, respectively. After that, a 15-nm thick Ru layer was laminated as a second underlayer in a 3-Pa Ar environment.

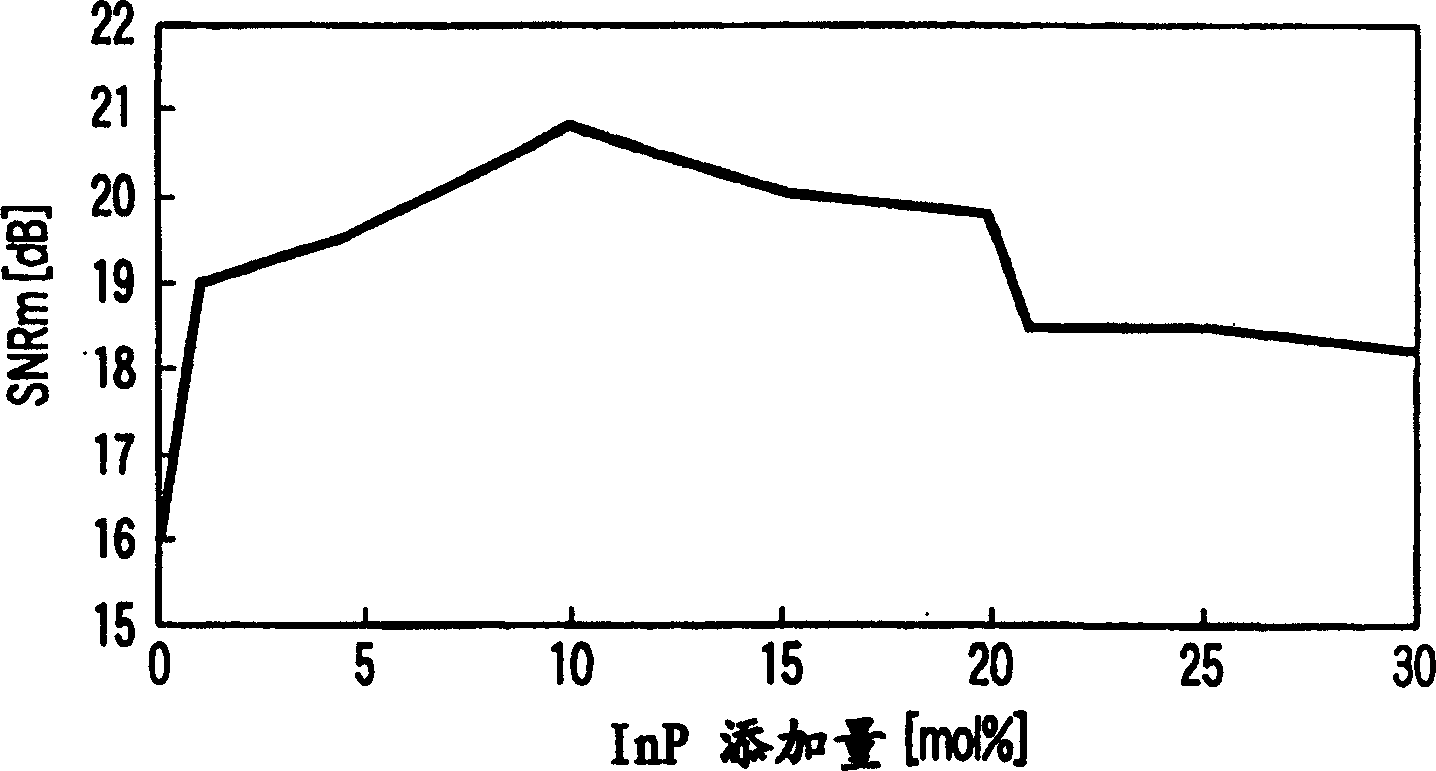

[0059] Subsequently, a composite target was obtained by adding 0-30 mol% InP as a matrix material to Co-10at%Cr-14at%Pt as a magnetic grain material, through which a 20-nm thick magnetic recording layer. Afterwards, a 7-nm thick C layer was stacked as a protective layer in a 0.67-Pa Ar environment. After the thin film was formed, the surface of the protective layer was coated with a 13 Å thick perfluoropolyether (PEPE) lubricant by dipping to obtain a magnetic recordi...

specific Embodiment approach 2

[0078] Prepare a non-magnetic glass substrate in the shape of a 2.5-inch hard disk.

[0079] The vacuum chamber of a sputtering device is evacuated to 2 x 10 -5 After -Pa or less, a 5-nm thick Ta layer was formed as a first underlayer in a 0.67-Pa Ar atmosphere. After that, a 15-nm thick Ru layer was laminated as a second underlayer in an 8-Pa Ar environment.

[0080] Subsequently, under an Ar environment of 8-Pa, using a Co-10at%Cr-14at%Pt target as the magnetic grain material and an InP target as the matrix material, a 15-nm thick magnetic film was formed by simultaneous sputtering of the two targets. record layer. During the sputtering process, the electric power for each target was controlled to be able to properly vary the addition amount of the matrix material between 0-30 mol% relative to the magnetic grain material. Then a 7-nm thick C layer was stacked as a protective layer in a 0.67-Pa Ar environment. After film formation, the surface of the protective layer was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com