Magnesium alloy twin-roll continuous casting method and device for manufacturing magnesium alloy plate

A technology for plate production and casting equipment, which is applied in the field of magnesium alloy continuous casting methods and equipment, and can solve the problems of inability to use magnesium alloys for smelting and transportation, inapplicability, and harshness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

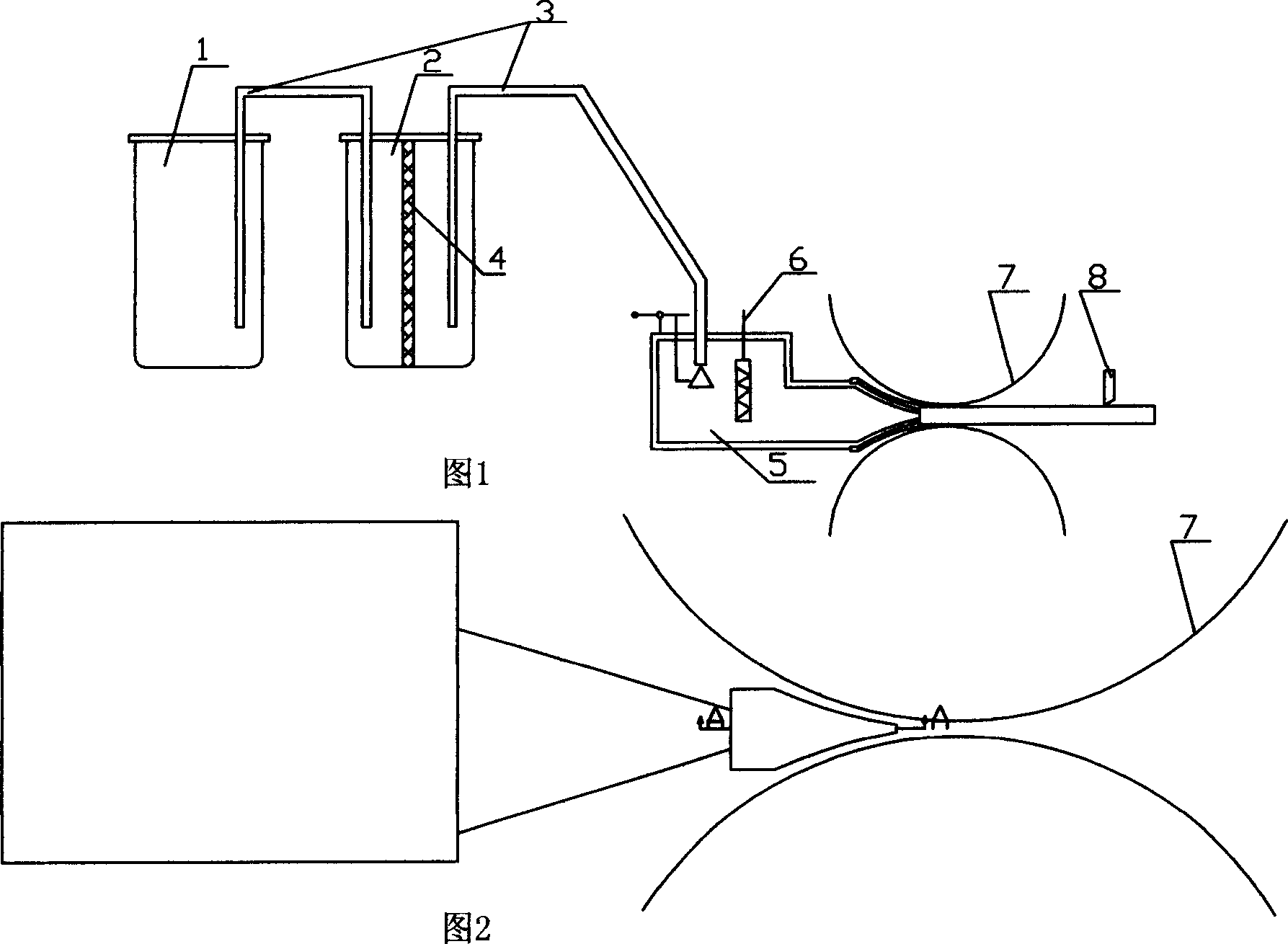

Embodiment 1

[0016] The magnesium alloy smelting and heat preservation system adopts double furnaces. The melting furnace 1 uses a resistance furnace or a power frequency furnace to melt the magnesium alloy. The melting temperature can be 740°C. The resistance heat preservation furnace is used to process the magnesium alloy liquid, and the heat preservation temperature can be 720°C. The magnesium alloy liquid is automatically conveyed by a siphon or a pump. The magnesium alloy liquid level control of the front box nozzle adopts automatic and manual dual control devices. As long as the constant height is maintained, the magnesium alloy liquid can be kept at a constant temperature in the front box nozzle, and the constant temperature can be adjusted. It is 720°C.

Embodiment 2

[0018] In the case that the magnesium alloy smelting and heat preservation system adopts a double furnace, a plate-shaped magnesia foam ceramic filter can be used in the heat preservation furnace to divide the magnesium alloy liquid into two parts. The ceramic foam filter is made of pure MgO fired at high temperature, its thickness is 20-40 mm, the porosity is about 85%, and the pore size is 20-40 mesh. The foam ceramic filter can filter the magnesium alloy liquid when it flows through, and can greatly reduce the content of non-metallic impurities in the magnesium alloy liquid. If the ceramic foam filter is expected to have the ability to filter metal impurities at the same time, its composition can be adjusted or the surface of the fired product can be modified.

Embodiment 3

[0020] Under the conditions of Embodiment 1 or / and Embodiment 2, an internal thermoelectric heater or an external heating device with a power of 2 to 5 kilowatts can also be placed in the front box nozzle, and the internal thermoelectric heater can be set according to the required temperature. On-line monitoring with thermocouples, adjusting the temperature of the magnesium alloy liquid through thermocouple sensors and automatic equipment can keep the magnesium alloy liquid at a constant temperature, and the constant temperature can be 720°C to meet the temperature requirements of the casting and rolling process for the magnesium alloy liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com