Process for preparing amino acid chelated calcium and its special device

A special equipment, amino acid technology, applied in the preparation of organic compounds, chemical instruments and methods, cyanide reaction preparation, etc., can solve the problems of low chelation rate, incomplete reaction, long preparation time, etc., and achieve chelation rate High, complete response, continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

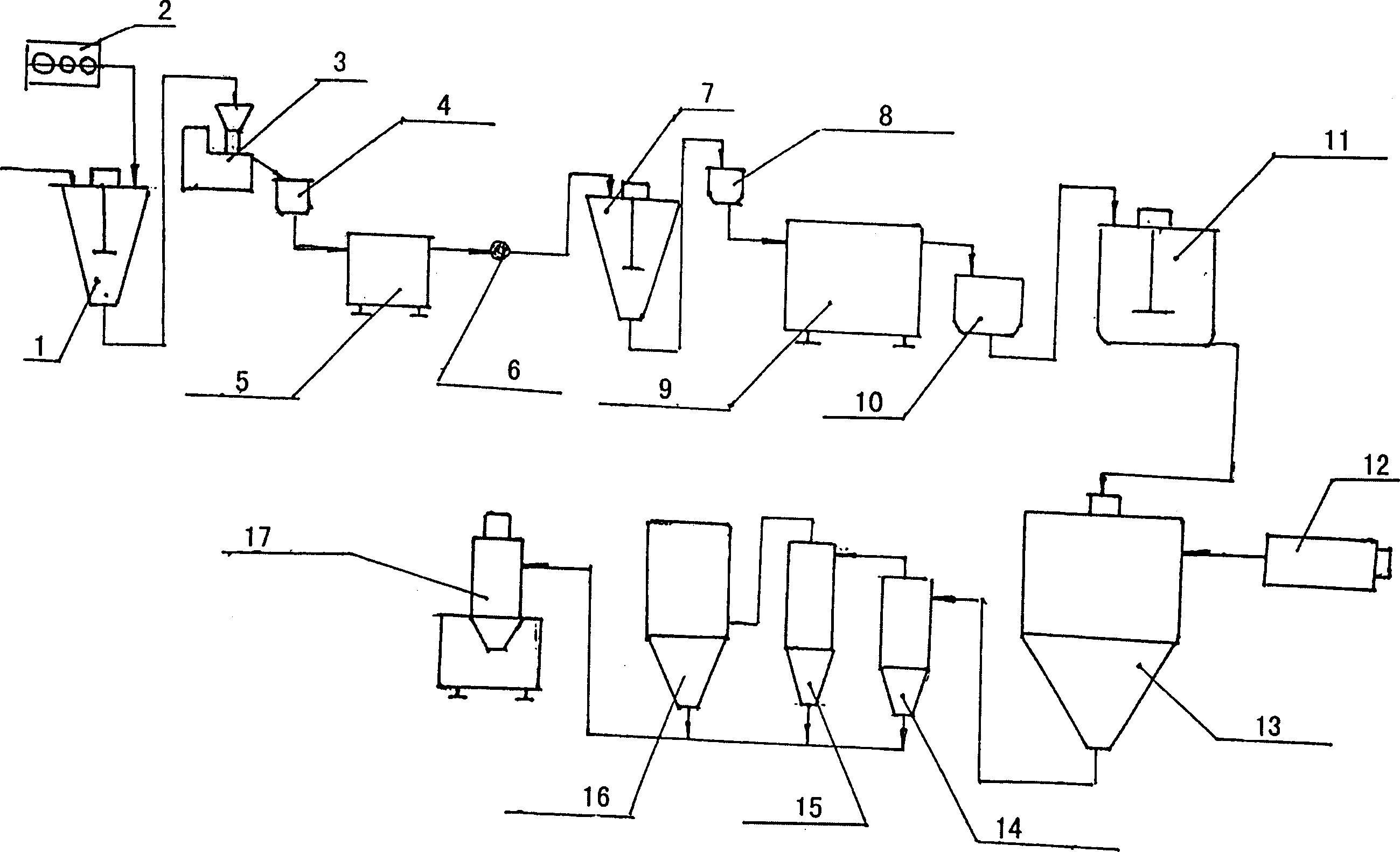

[0019] Such as figure 1 As shown, first pour L-aspartic acid and calcium hydroxide into a double-helix cone mixer (1 cubic meter) with a weight ratio of 3.8:1 to mix, then add fully automatic 0.5TRO reverse osmosis, sterilized pure water The pure water processed by equipment 2 is fully stirred; then it passes through the 110-type colloid mill 3, the steady flow box 4, the homogenizer 5 and the filter 6 and enters the double-helix cone mixer (5 cubic meters) 7 and passes through the steady flow Chest 8, obtains the mixed liquor that average particle size is 20 microns, total concentration is 25% (percentage by weight); This mixed liquor enters high-pressure fluid nanomill 9, and the pressure of controlling this nanomill is 90MPA; The liquid L-asparagus that obtains Amino acid chelated calcium enters storage barrel 10; Gained liquid L-aspartic amino acid chelated calcium passes through stirring stocker 11, drier 13 (connected with burner 12 for hot air), accumulator 14, collecto...

Embodiment 2

[0021] First pour glutamic acid and calcium hydroxide into a double-helix conical mixer (1 cubic meter) 1 with a weight ratio of 2.8:1 and mix them, then add the pure water, fully stirred; then through the 110-type colloid mill 3, the steady flow box 4, the homogenizer 5 and the filter 6 into the double-helix cone mixer (5 cubic meters) 7 and through the steady flow box 8 to obtain an average Particle size is 30 microns, the mixed solution that total concentration is 30% (percentage by weight); This mixed solution enters high-pressure fluid nanomill 9, and the pressure of controlling this nanomill is 130MPA; The liquid glutamic acid chelated calcium that obtains enters storage material Bucket 10; Gained liquid chelated calcium glutamate passes through stirring stocker 11, drier 13 (connecting with the burner 12 that gives hot blast), accumulator 14, accumulator 15, accumulator 16 successively again, Enter packing machine 17, obtain white powdery calcium glutamic acid chelate. ...

Embodiment 3

[0023] First pour lysine and calcium hydroxide into a double-helix cone mixer (1 cubic meter) 1 with a weight ratio of 3.3:1 and mix them, then add the pure water, fully stirred; then through the 110-type colloid mill 3, the steady flow box 4, the homogenizer 5 and the filter 6 into the double-helix cone mixer (5 cubic meters) 7 and through the steady flow box 8 to obtain an average Particle size is 15 microns, and total concentration is the mixed liquor of 10% (percentage by weight); This mixed liquor enters high-pressure fluid nanomill 9, and the pressure of controlling this nanomill is 110MPA; The liquid lysine chelated calcium that obtains enters storage material Bucket 10; Gained liquid lysine chelated calcium passes through stirring stocker 11, drier 13 (connecting with the burner 12 that gives hot air), accumulator 14, accumulator 15, accumulator 16 successively again, Enter packing machine 17, obtain white powdery lysine chelated calcium.

[0024] The biggest physical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com