Method for filtering engine lubricating oil and devices

A filter device and engine technology, which is applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve the problems of difficult filtration of fine particles in lubricating oil, etc., and achieve the effects of improving service life, easy disassembly, cleaning and replacement, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

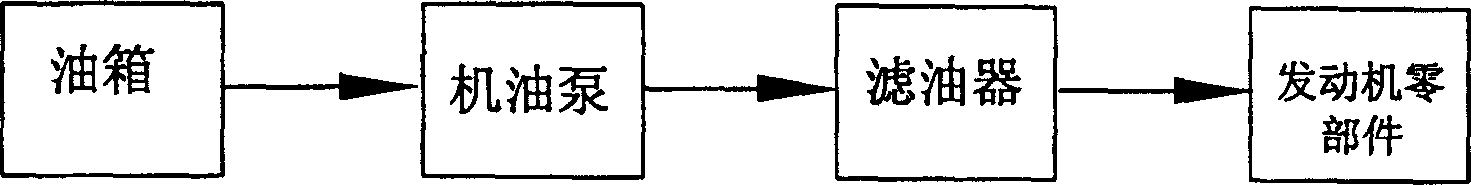

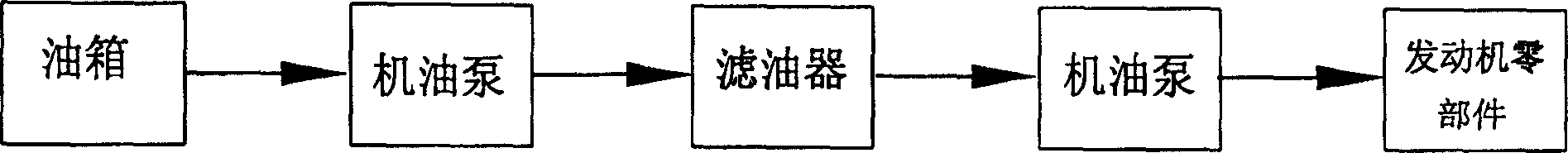

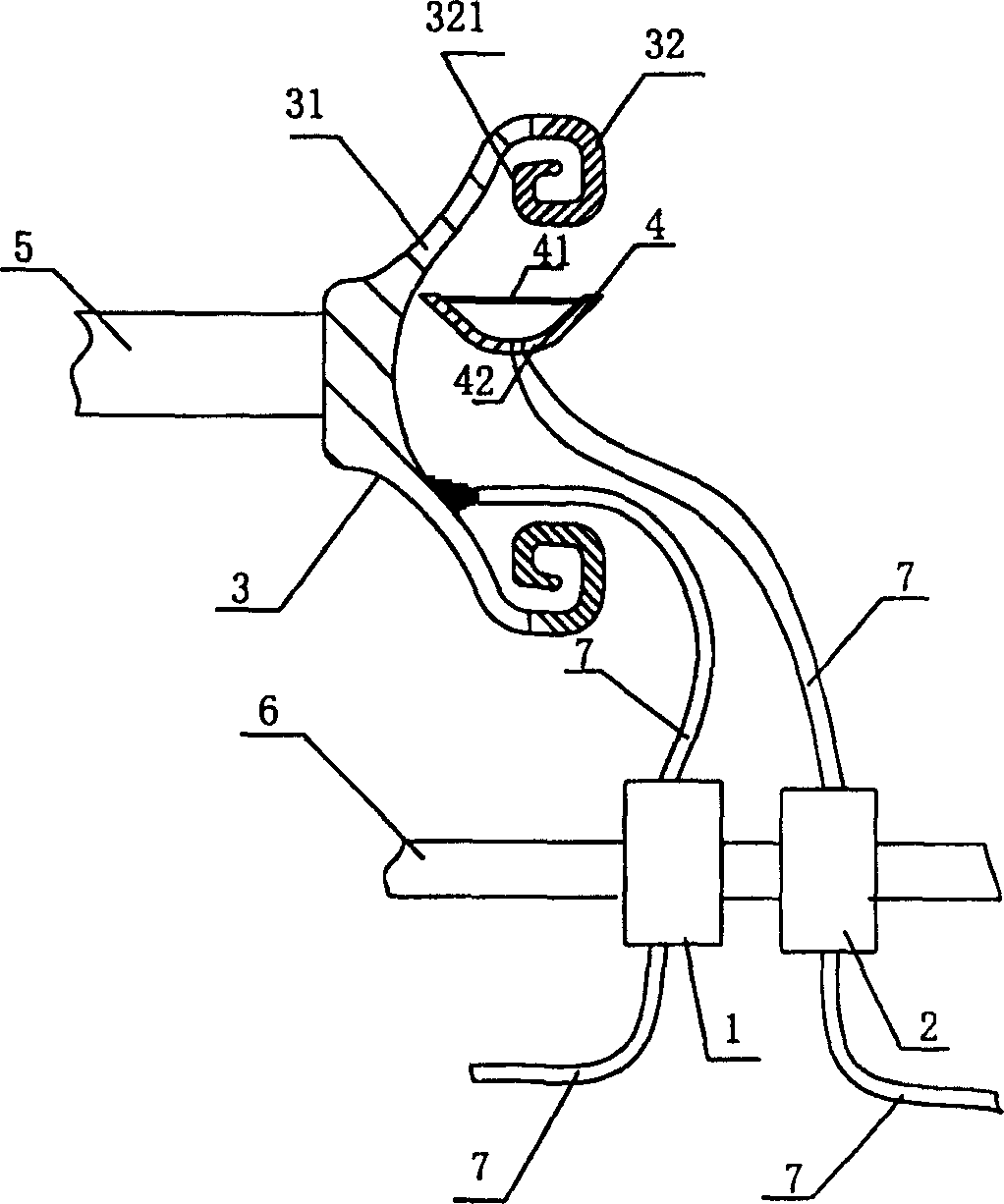

[0015] Embodiment, the filtration method and device of engine lubricating oil of the present invention, as figure 1 As shown, it includes two oil pumps 1, 2, tray 4, oil filter pipe 3, oil pipe 7 and bracket 8, engine main shaft 6 and engine crankshaft 5, two oil pumps 1, 2 are fixed on the engine main shaft 6, and the oil filter The filter 3 is fixed on the crankshaft 5 of the engine, the oil inlet of one of the oil pump 1 is connected to the fuel tank through the oil pipe, the mouth of the oil outlet pipe is eccentrically opposite to the disk surface of the oil filter 3, and the tray 4 is fixed on the engine shell through the bracket 8, And it is connected with the oil inlet of the second oil pump 2 through the oil pipe 7; the oil filter 3 is composed of a rotor 31 and a retaining ring 32. The rotor 31 is trumpet-shaped, the retaining ring 32 is provided with a barb 321 , the trumpet-shaped rotor 31 is fixedly connected with the retaining ring 32 , the tray 4 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com