Perfluorinated hydrocarbon polymer-filled adhesive formulations and use thereof

A perfluorinated hydrocarbon and binder technology, used in non-polymeric organic compound binders, adhesives, semiconductor/solid-state device parts and other directions to achieve good rheological effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0125] Prepare the viscose composition by thoroughly mixing the Teflon powder and the thermosetting resin carrier in a bowl. The resin carrier that adopts is made up of following composition (percentage by weight):

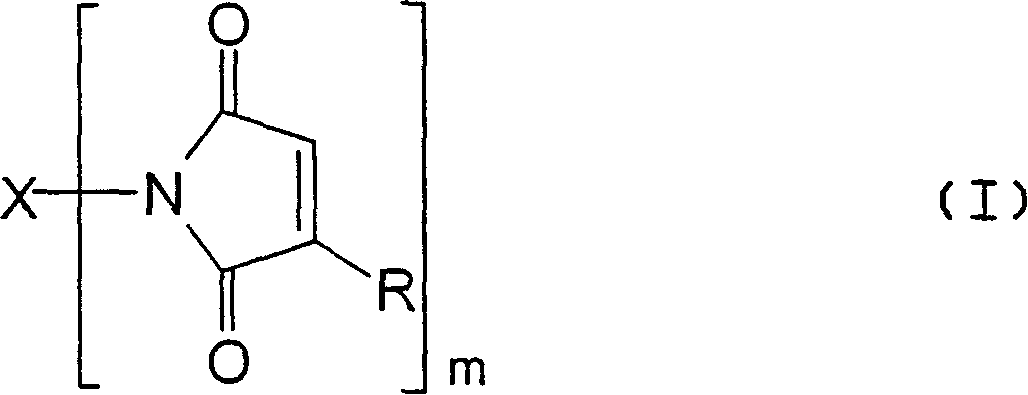

[0126] 60% 1,20-bismaleimido-10,11 dioctyl-eicosane (BMI, see USSN 08 / 300,721 and 08 / 460,495, both of which are hereby incorporated by reference) ,

[0127] 13.0% Ricon 130MA-20 (available from Ricon Resins, Inc., Grand Junction, CO),

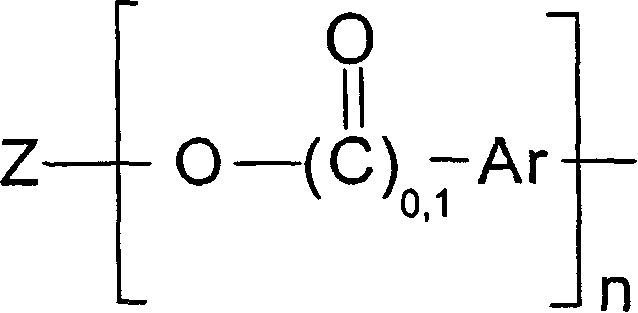

[0128] 22.0% 1-vinyloxy-2-decyltetradecane (see USSN 08 / 300,721 and 08 / 460,495, both of which are hereby incorporated by reference),

[0129] 1.0% USP90MD (a peroxide catalyst available from Witco Corporation, Argus Division, Marshall, TX), and

[0130] 3% Silquest A-186 plus 1% Silquest A-174 (coupling agents both available from OSI Specialities, Inc., South Charleston, WV).

[0131]The Teflon powder used was DuPont's product 1600N (available from DuPont Fluroproducts, Wilmington, DE). 40% by weight of this filler was mixed i...

example 2

[0135] A second viscose composition was prepared as outlined in Example 1. The same resin carrier and Teflon filler were used. But this time the composition was formulated to contain 45% by weight filler. The resulting viscose had a Brookfield 10 rpm viscosity of 24,490 centipoise and a 1 / 20 thixotropic index of 13.53.

[0136] The silicon chip was then attached to the silver plated copper lead frame as described in Example 1 using the adhesive prepared above. The cured part had an average room temperature die shear of 15.47 kgf and a hot (ie, 245°C) die shear of 4.08 kgf.

[0137] A thermal analysis of the viscose was additionally carried out. The TGA (thermogravimetric analysis) method measured a weight loss of 2.69% at 250°C. According to the DSC (differential scanning calorimetry) method, the maximum value of the temperature rise was 128.0°C.

example 3

[0139] A third viscose composition was prepared following the procedure described in Example 1. The same resin carrier and Teflon filler were used. But the weight percent of filler is reduced to 35% by weight of the composition. The resulting viscose had a Brookfield 10 rpm viscosity of 7332 centipoise and a 1 / 20 thixotropic index of 6.96.

[0140] The silicon chip was then attached to the silver plated copper lead frame as described in Example 1 using the adhesive prepared above. The cured part had an average room temperature die shear of 14.30 kgf and a hot (ie, 245°C) die shear of 4.01 kgf.

[0141] Thermal analysis of the viscose was carried out as outlined in Example 1. The TGA (thermogravimetric analysis) method measured a weight loss of 2.77% at 250°C. According to the DSC (differential scanning calorimetry) method, the maximum temperature rise was 128.17°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com