Citric acid aqua process of preparing sheet PZT powder

A technology of citric acid aqueous solution and lead zirconate titanate is applied in the field of preparation of ferroelectric ceramic materials, which can solve the problems of difficult sintering of PZT ceramic materials, expensive raw materials, and difficulty in the source of PZT powder raw materials, and achieves simple equipment and chemical uniformity. Good and easy micro-doping modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

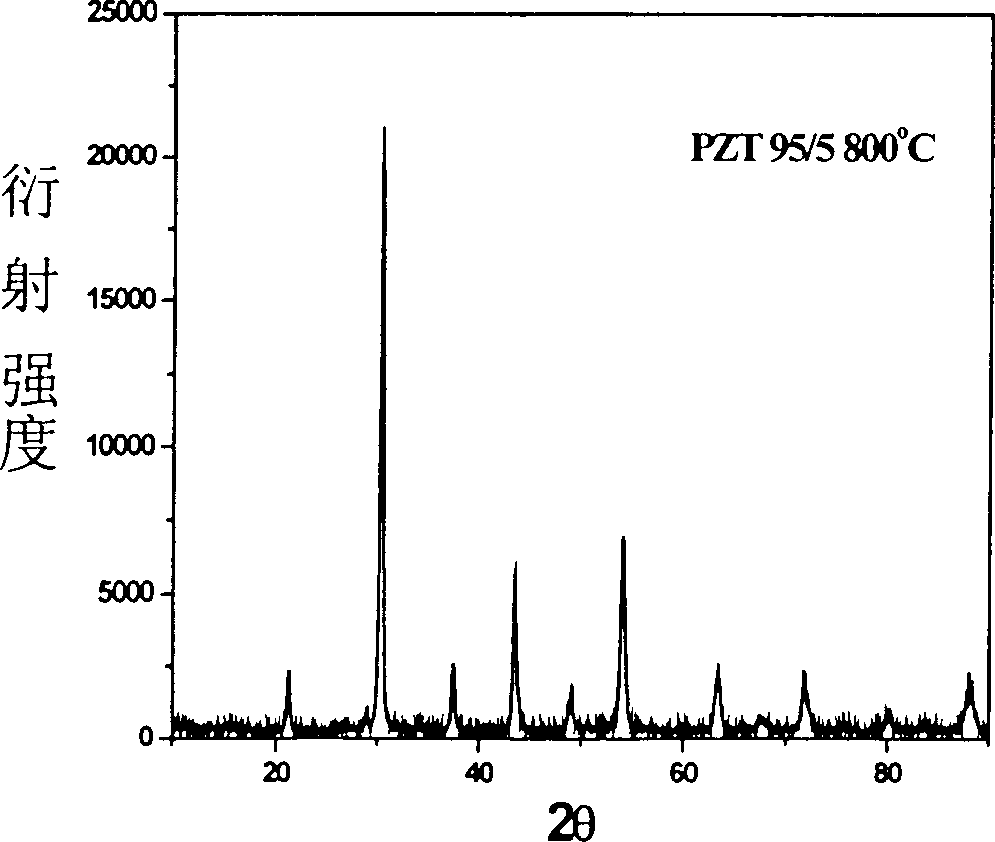

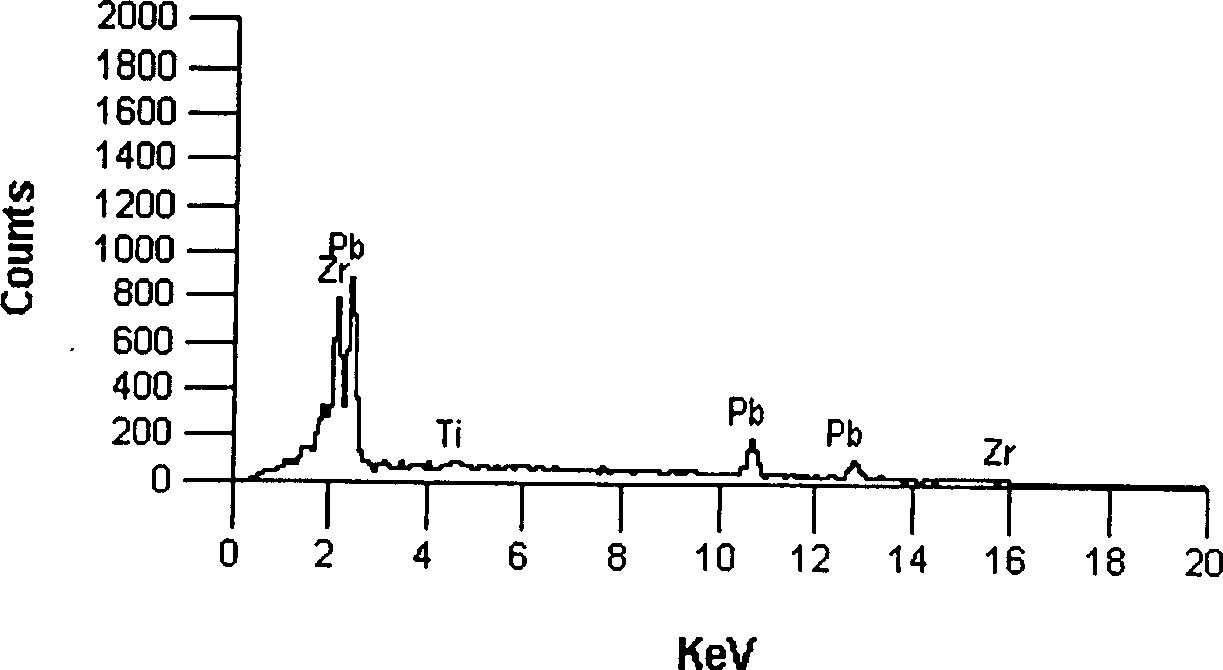

[0015] Add 0.3mol citric acid to 150g deionized water, then add 0.055mol lead nitrate (10% excessive compensation heat treatment Pb loss), 0.0473mol zirconium nitrate, heat and stir in a water bath at 70°C for 2 hours to form a white emulsion, then add 0.0025mol positive Tetrabutyl titanate was stirred for 0.5 hours, and ammonia water was added to adjust the pH to 6.5, and the emulsion gradually became clear. Continue heating and stirring in a water bath for 8 hours to obtain a colorless and transparent homogeneous sol. Dry the prepared precursor in a drying oven at 150°C, and bake it in a drying oven at 250°C after the water is completely volatilized until it burns. After the combustion, the powder is heat-treated in a muffle furnace at 800°C for 1.5 hours to obtain powder needed.

Embodiment 2

[0017] Add 0.18 mol of citric acid to 100 g of deionized water, then add 0.033 mol of lead nitrate (10% excess compensation for heat treatment Pb loss), 0.0285 mol of zirconium nitrate, heat and stir in a 70°C water bath for 1.5 hours to form a white emulsion, and then add 0.0015 mol of Tetrabutyl orthotitanate was stirred for 1 hour, and ammonia water was added to adjust the pH to 7.5, and the emulsion gradually became clear. Continue heating and stirring in a water bath for 7 hours to obtain a colorless, transparent and uniform sol. Dry the prepared precursor in a drying oven at 170°C, and bake it in a drying oven at 240°C after the water is completely volatilized until it burns. After the combustion, the powder is heat-treated in a muffle furnace at 700°C for 2 hours to obtain powder needed.

[0018] From figure 1 It can be seen that the prepared PZT95 / 5 is sheet-like with a single shape; from figure 2 It can be seen that the XRD of the prepared powder is consistent wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com