Combustion method of fossil fuel and equipment thereof

A combustion device, a technology for fossil fuels, applied in combustion methods, burners for burning powder fuels, burners, etc., can solve problems such as rapid progress of adverse reactions, and achieve the effects of reducing burden, environment-friendly operation, and improving combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

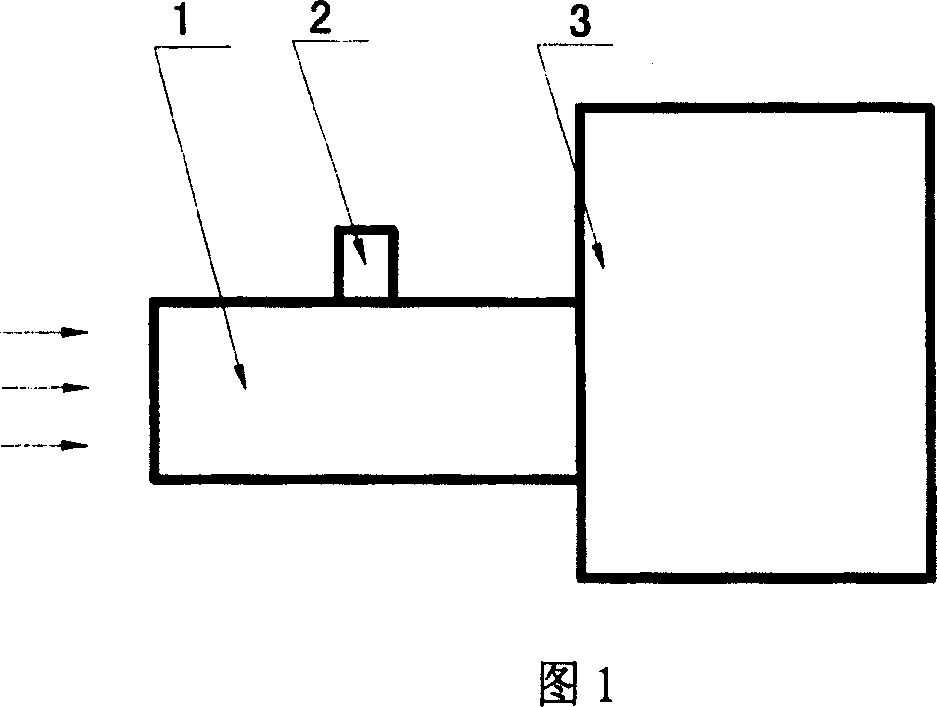

[0014] A combustion method for increasing the oxygen concentration of powder-containing airflow provided by the present invention is characterized in that oxygen is added before the primary airflow carrying powder fuel enters the combustion chamber, so that its oxygen concentration is appropriately increased, and the oxygen concentration is 22 ~35%, the powder-containing airflow before entering the combustion chamber includes the airflow carrying fuel powder entering the primary air duct, or the concentrated airflow after passing through the thick-lean separator. Fig. 1 is a schematic structural principle diagram of an embodiment provided by the present invention. It is mainly composed of a primary air duct 1, an oxygen inlet channel 2 and a combustion chamber 3; the oxygen inlet channel is arranged on the primary air duct 1.

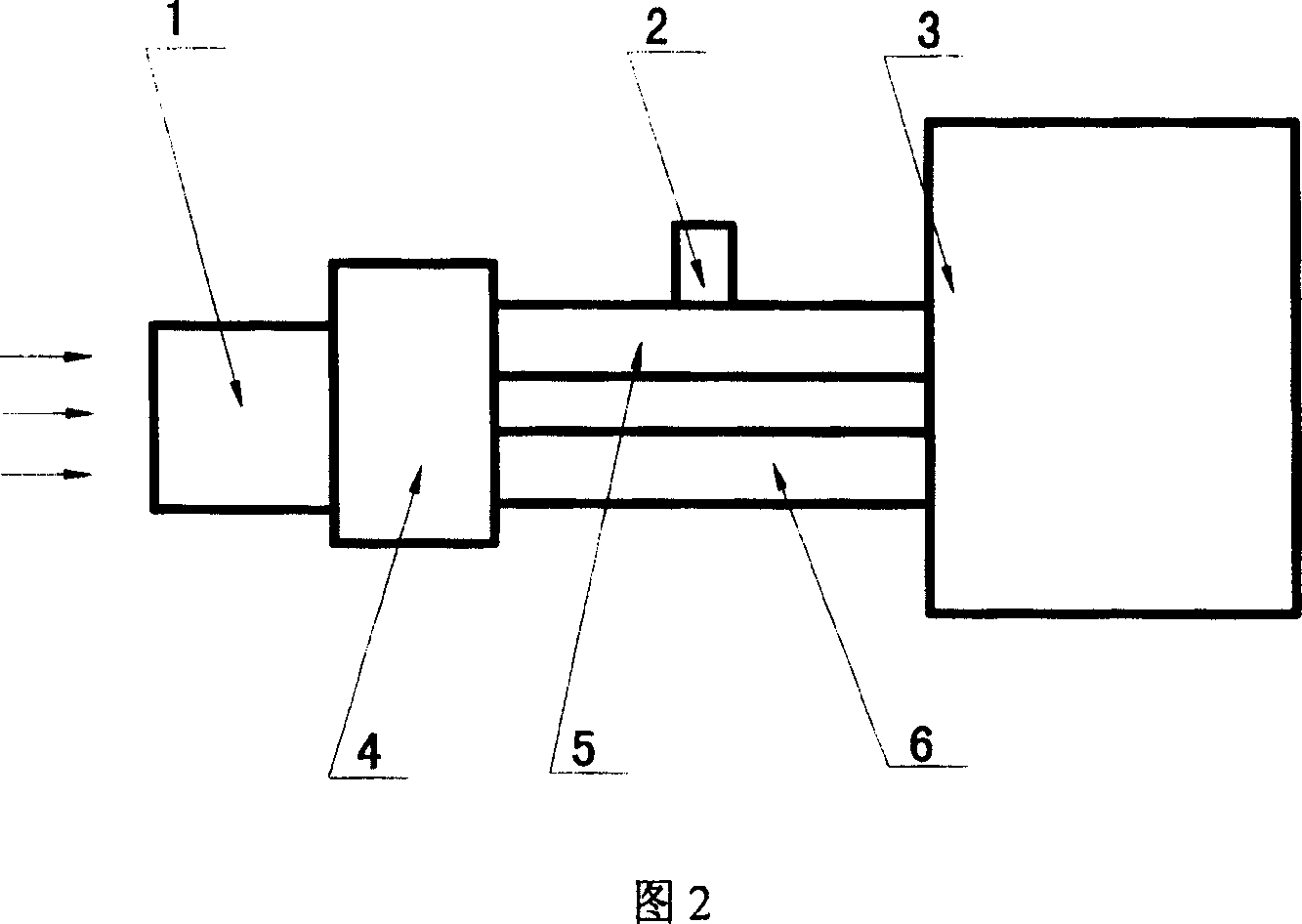

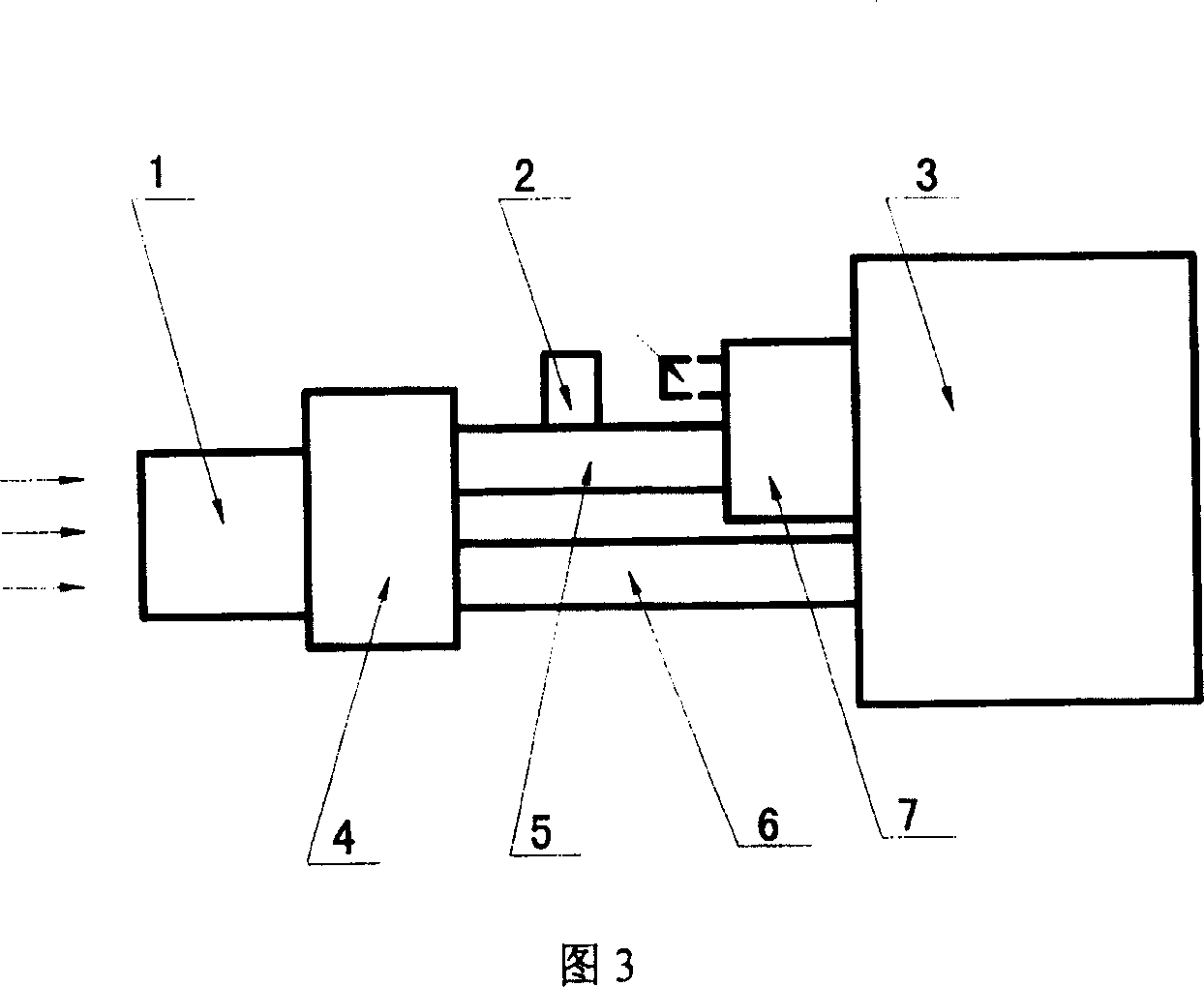

[0015] In order to save oxygen, on the basis of the above scheme, the present invention is combined with the rich-lean combustion technology (ie, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com