Method for producing calcium hydrogen phosphate fodder

A technology of calcium dihydrogen phosphate and its production method, which is applied in the field of calcium dihydrogen phosphate, can solve the problems of high production cost of thermal phosphoric acid, high cost of calcium dihydrogen phosphate, and high price, and improve equipment utilization rate and phosphorus content The effect of high and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

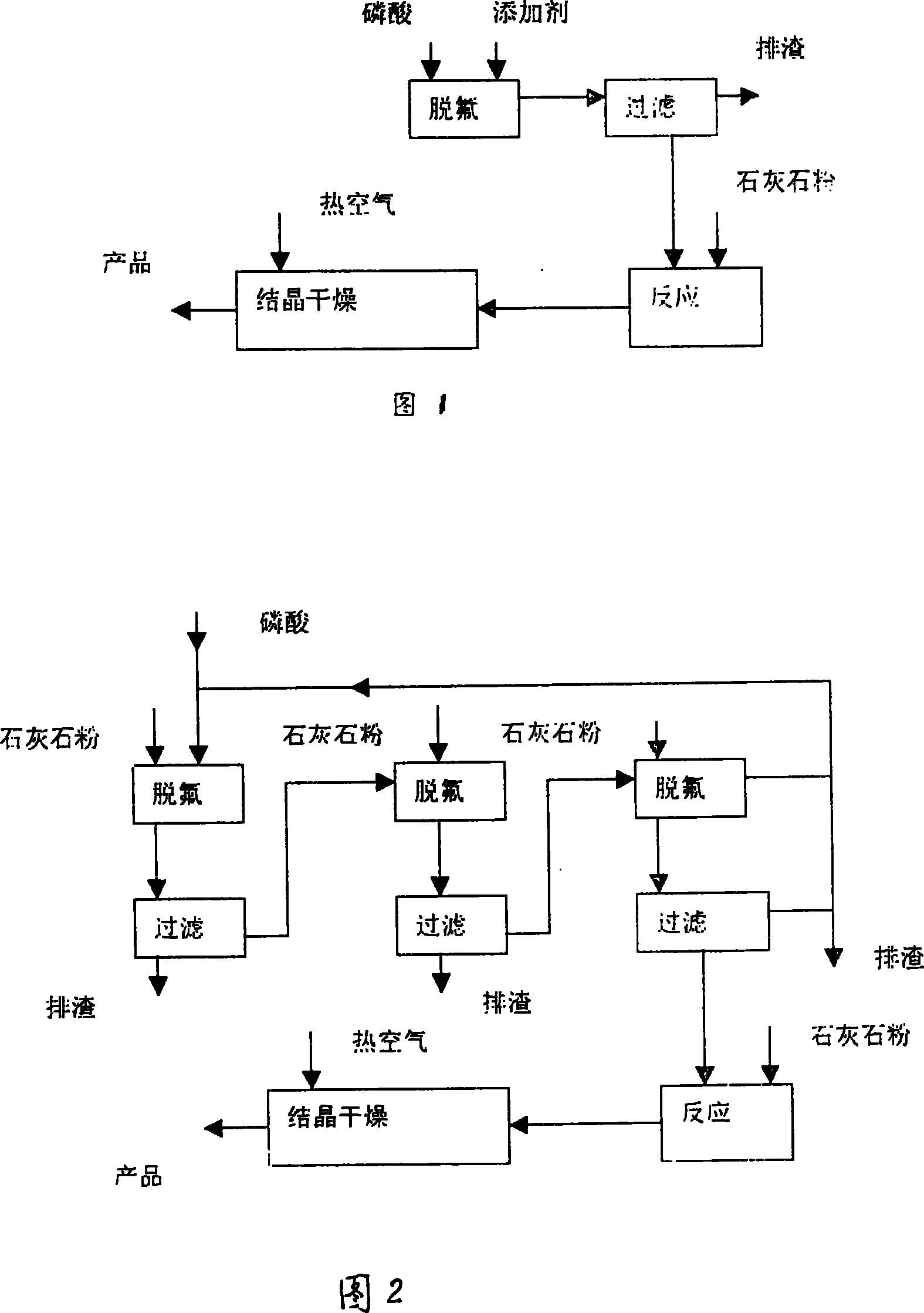

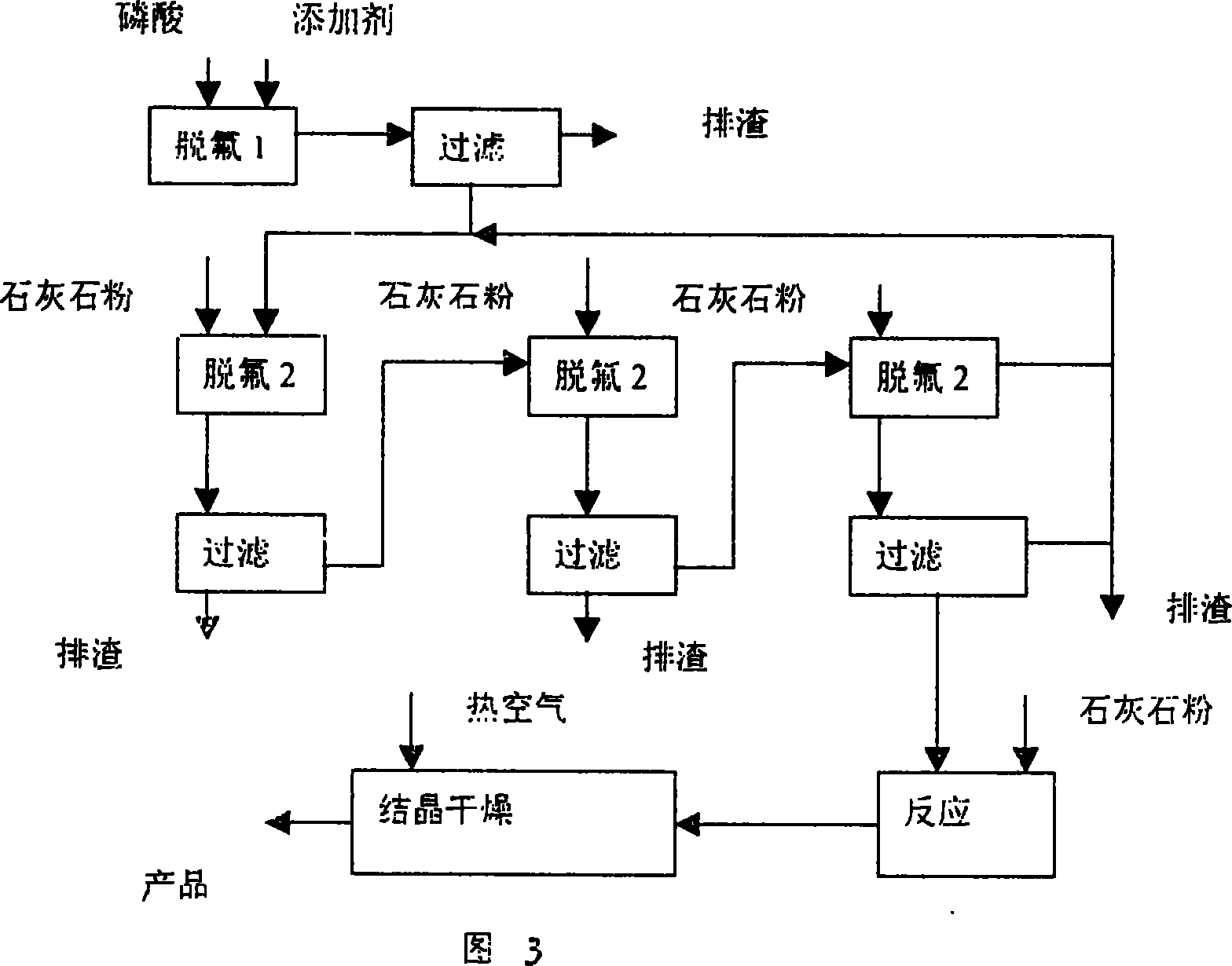

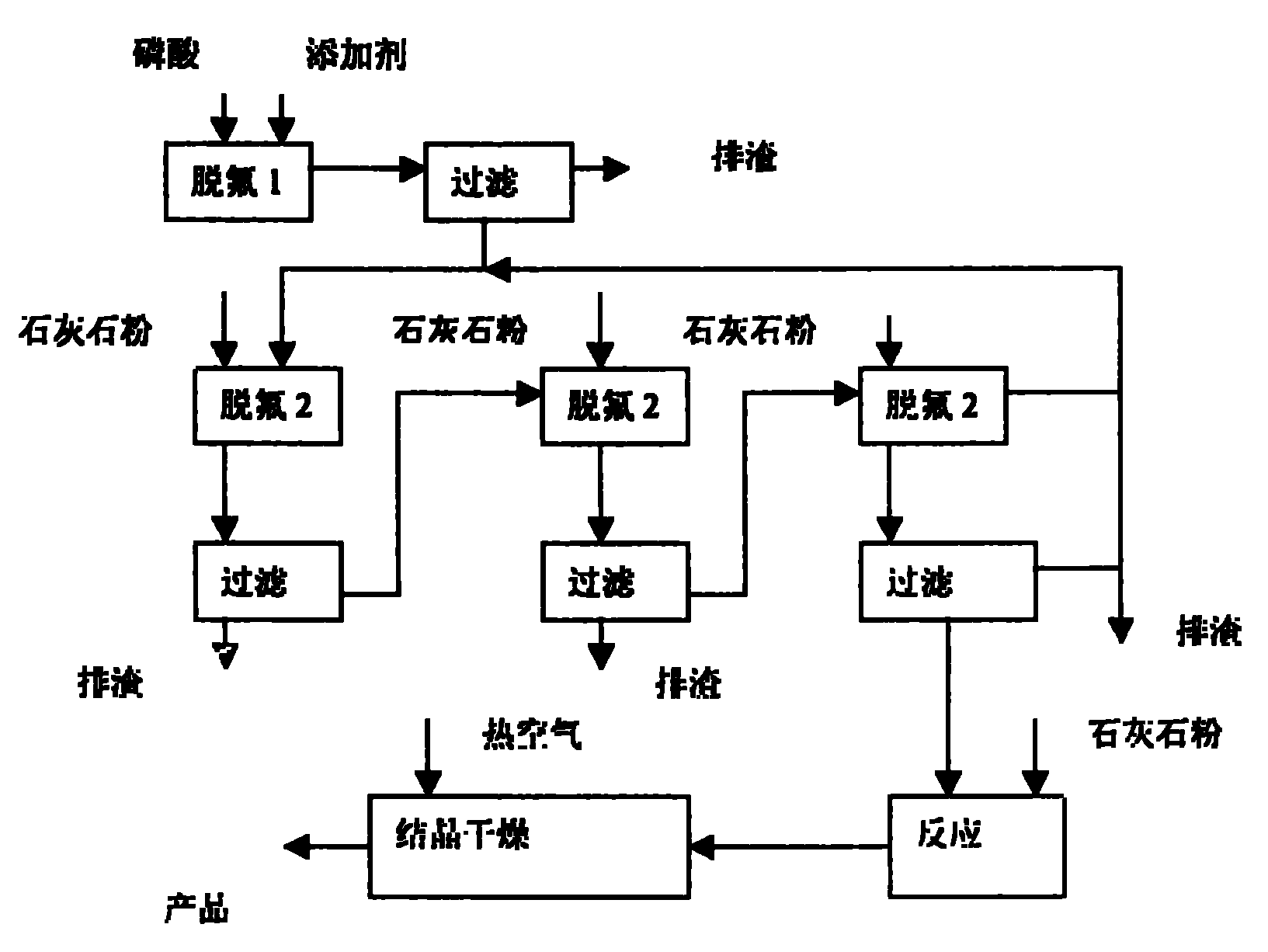

Method used

Image

Examples

Embodiment 1

[0025] P produced from Jinhe Phosphate Mine in Sichuan 2 o 5 Content is about 18%, fluorine content is about 100 parts (weight) of wet-process phosphoric acid of 2.23%, as the sodium sulfate 2 parts (weight) of impurity remover, as the hydroxyethyl pyrophosphoric acid 0.02 parts (weight) of additive, add In the reaction tank equipped with a stirrer, the reaction temperature is kept at about 70° C., and the reaction is carried out for about 45 minutes under the condition of stirring. After the reaction, the feed liquid is added to the centrifugal filter for filtration, and the filter residue is removed. The filtrate enters the purification reactor equipped with an agitator again, and at the same time, limestone powder is added to carry out the purification reaction. The reaction temperature is about 45°C. Stir and add limestone powder to control the pH value of the reaction feed liquid at about 2.6, and react for about 50 minutes to precipitate impurities from phosphoric acid....

Embodiment 2

[0027] P produced from Kaiyang Phosphate Mine in Guizhou 2 o 5 100 parts of wet-process phosphoric acid with a content of about 20.9% and a fluorine content of about 1.74%, 2.2 parts of sodium sulfate as an impurity remover, and 0.015 parts of hydroxyethyl pyrophosphate as an additive are added to a reaction tank equipped with a stirrer. Reaction, the reaction temperature is about 70°C, stirring is carried out during the reaction, and the reaction time is about 45 minutes. The feed liquid is sent to a centrifugal filter for filtration to remove the filter residue, and the filtrate is clean phosphoric acid for the production of calcium dihydrogen phosphate. Send the purified phosphoric acid into a slurry reactor equipped with a stirrer, and at the same time add 15.6 parts (by weight) of limestone powder for slurry reaction. The reaction temperature is about 75°C. Stir during the reaction until the reaction reaches When the solid phase concentration in the slurry reaches about...

Embodiment 3

[0029] Phosphate produced from Yichang Phosphate Mine in Hubei 2 o 5 Content is about 15%, fluorine content is about 100 parts (weight) of wet-process phosphoric acid of 1.85%, calcium carbonate powder 2.1 parts (weight), add the reactor that is provided with stirrer, the pH value of feed liquid is controlled at about 2.8 . The reaction temperature is about 45°C, stirred during the reaction, and reacted for about 40 minutes. The feed liquid is sent to a centrifugal filter for filtration to remove filter residue, and the filtrate enters the lower purification reactor, and 1.1 parts (by weight) of limestone powder are added to make the feed liquid The pH value is controlled at about 3.1, the reaction temperature is kept at about 40°C, and stirring is carried out at the same time, and the reaction time is about 40 minutes. Send the feed liquid to a centrifugal filter for filtration, remove the filter residue, and the filtrate enters a slurry reactor equipped with an agitator, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com