Epoxidation system with fixed bed reactors

A fixed-bed reactor, reactor technology, applied in the direction of organic chemistry, etc., can solve problems such as poor economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

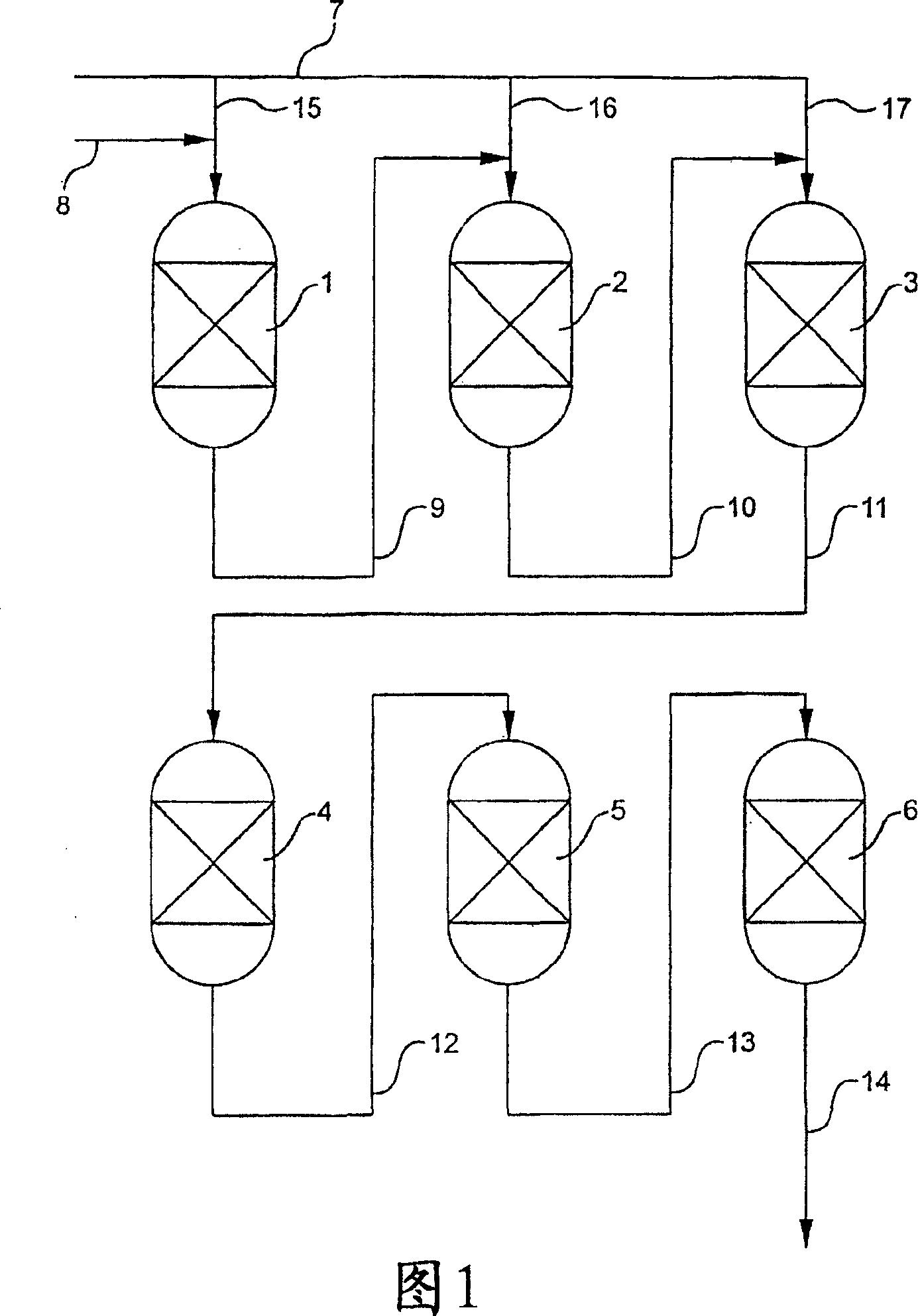

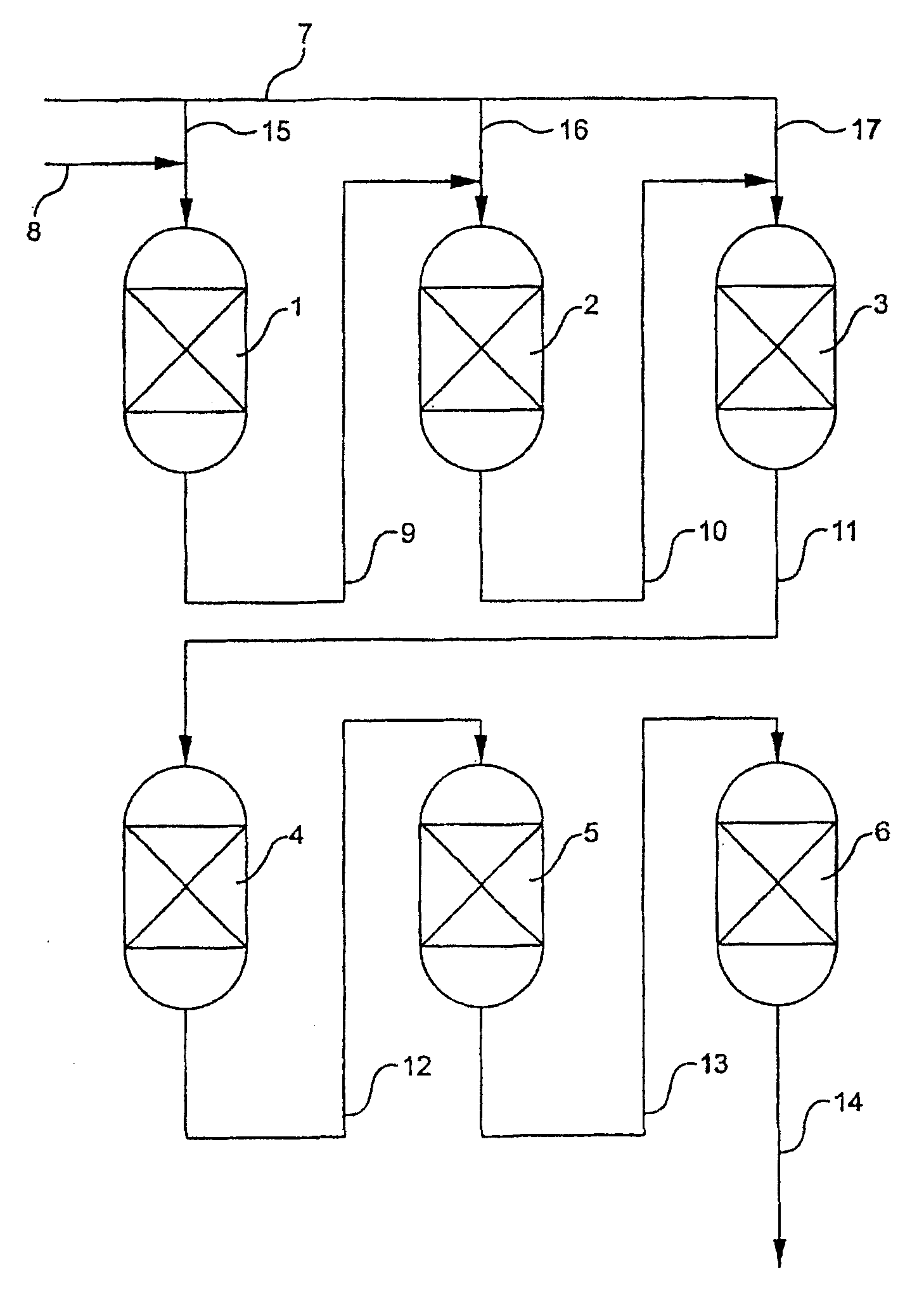

[0037] Ethylbenzene oxide, consisting of 56.8% by weight ethylbenzene, 35.0% by weight ethylbenzene hydroperoxide, and 8.2% by weight other materials, passes through line 7 at a rate of about 592,857 lbs / hr. Of this, about 197,600 lb / hr is sent to reactor 1 via line 15, about 197,600 lb / hr is sent to reactor 2 via line 16 and about 197,600 lb / hr is sent to reactor 3 via line 17. The reactors were of approximately the same size and each contained a solid epoxidation catalyst of titanium / silica composition prepared according to the procedure of Example 1 of US 6,114,552.

[0038] A propylene feed consisting of 90.0% by weight propylene, 9.9% by weight propane and 0.1% by weight other materials was fed to Reactor 1 via line 8 at a rate of about 420,548 lbs / hr. The total molar ratio of propylene fed via line 8 to hydroperoxide fed via line 7 was about 6:1.

[0039] In Reactor 1, a mixture of propylene and ethylbenzene hydroperoxide enters the bed of epoxidation catalyst at 68°C and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com