Friction layer running in a medium

A friction layer and friction component technology, applied in friction linings, mechanical equipment, etc., can solve problems such as oil removal, time impact of switching process, and shortened synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

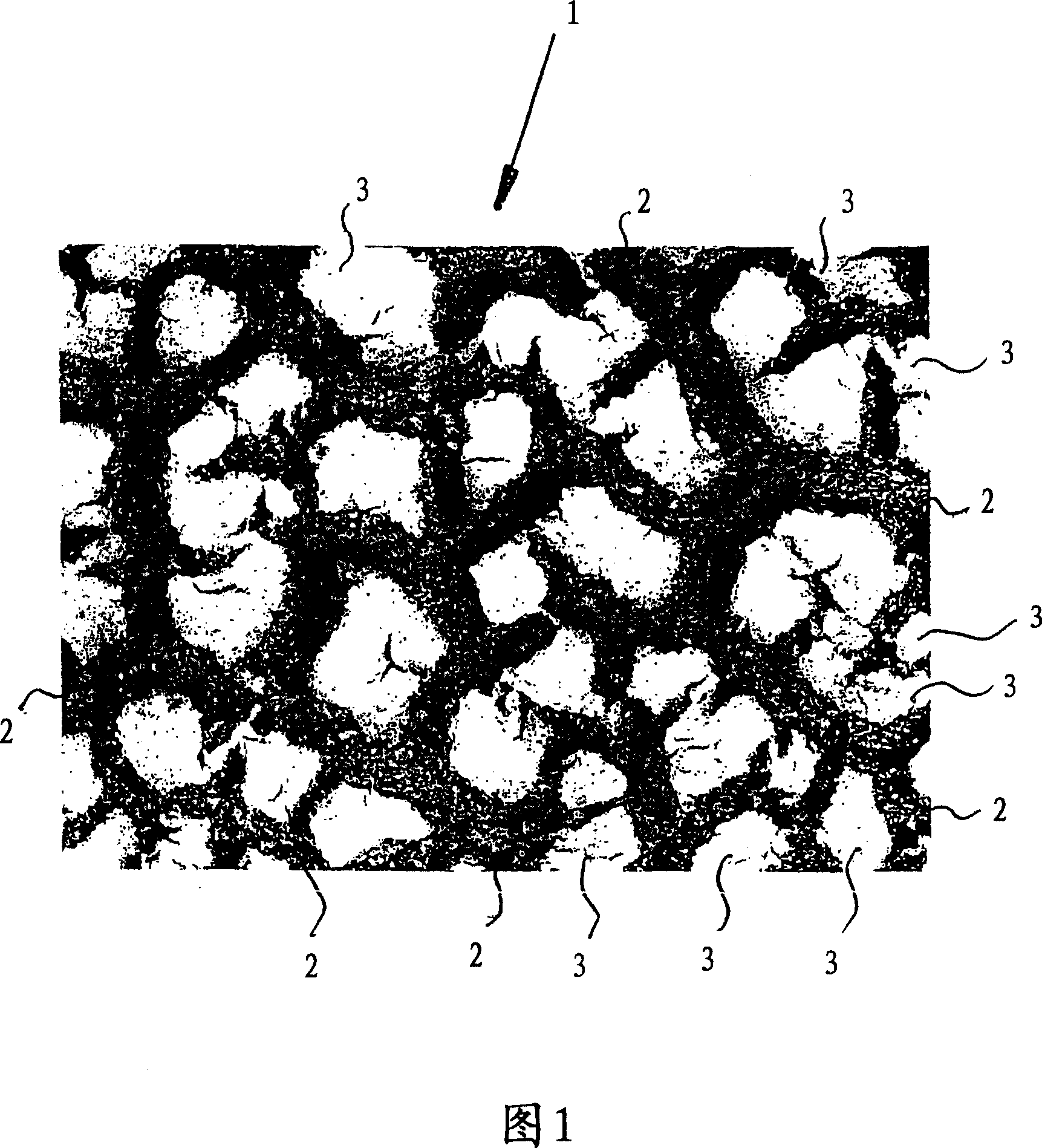

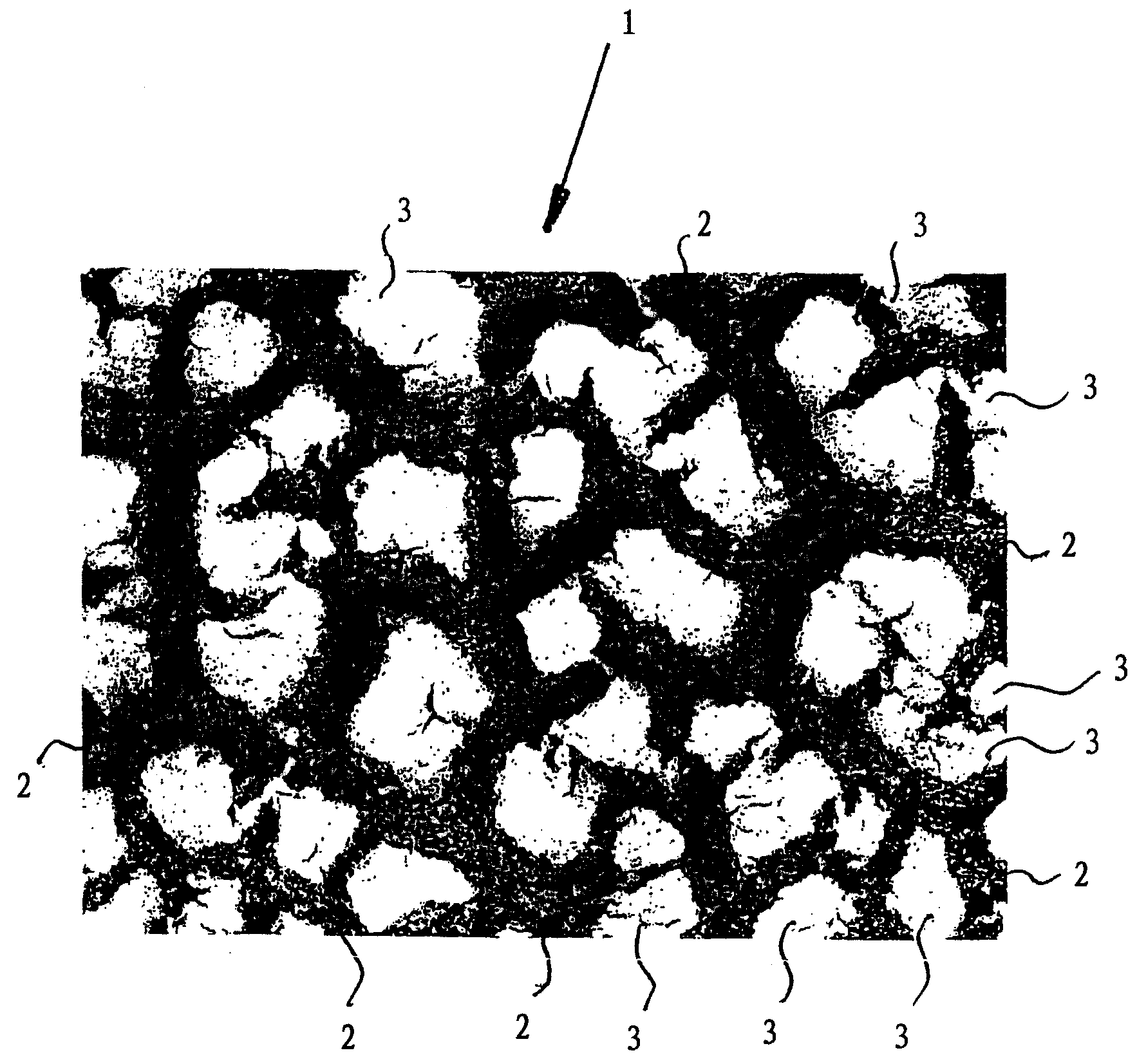

Image

Examples

Embodiment 1

[0033] 1. Materials

[0034] Powder: - Iron Oxide Powder (Fe 3 o 4 ), mass 8g,

[0035] - powder, the composition is 30% Mo, 9% Cr, 2.5% Si, the rest is Fe;

[0036] Mass 2g,

[0037] Binder: 2.5% aqueous solution of polyvinylpyrrolidone, volume 16ml.

[0038] 2. Mix the ingredients

[0039] The ingredients were mixed with a mixer for 10 minutes.

[0040]3. Coating

[0041] The mixture is atomized with compressed air and sprayed onto the inner cone of the rotating steel synchronizer ring. The spray thickness is 550 μm. After a drying time of about 5 minutes, the coating has a high green sand strength, which allows good handling of the rings.

[0042] 4. Binder removal, sintering and alignment

[0043] The debinder and sintering process can be performed in one step in the same furnace under hydrogen atmosphere. For this purpose, the furnace is heated at a heating rate of 5 K / min. The debinding process starts at about 300°C and ends at 600°C. The sintering process i...

Embodiment 2

[0061] 1. Materials

[0062] Powder: - Iron Oxide Powder (Fe 3 o 4 ), mass 8.2g

[0063] - graphite powder, mass 1.8g,

[0064] Binder: 2.5% aqueous solution of polyvinylpyrrolidone, volume 16ml.

[0065] 2. Mix the ingredients

[0066] The ingredients were mixed with a mixer for 10 minutes.

[0067] 3. Coating

[0068] The mixture is atomized with compressed air and sprayed onto the inner cone of the rotating steel synchronizer ring. The spray thickness is 700 μm. After a drying time of about 8 minutes, the sprayed coating has a high green sand strength, which allows good handling of the rings.

[0069] 4. Binder removal, sintering and alignment

[0070] The binder removal and sintering processes can be performed in one step in the same furnace under a hydrogen atmosphere. For this purpose, the furnace is heated at a heating rate of 5 K / min. The binder removal process starts at about 300°C and ends at 600°C. The sintering process takes place in the temperature ran...

Embodiment 3

[0087] 1. Materials

[0088] Powder: - copper oxide powder (CuO), mass 8.6g

[0089] - Zinc powder, mass 0.58g

[0090] - Graphite powder, mass 0.82g

[0091] Binder: 2.5% aqueous solution of polyvinylpyrrolidone, volume 16ml.

[0092] 2. Mix the ingredients

[0093] The ingredients were mixed with a mixer for 10 minutes.

[0094] 3. Coating

[0095] The mixture is atomized with compressed air and sprayed onto the inner cone of the rotating steel synchronizer ring. The spray thickness is 680 μm. After a drying time of about 8 minutes, the sprayed coating has a high green sand strength, which allows good handling of the rings.

[0096] 4. Binder Removal, Sintering and Calibration

[0097] The binder removal and sintering processes can be performed in one step in the same furnace under a hydrogen atmosphere. For this purpose, the furnace is heated at a heating rate of 5 K / min. The binder removal process starts at about 300°C and ends at 600°C. The sintering process ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com