Environmental protection, healthy new type leadless easy cutting corrosion resistant low boron calcium brass alloy

A brass alloy, easy-cutting technology, applied in valve parts, lead-free easy-cutting corrosion-resistant low-boron-calcium brass alloy, civil water supply system pipe castings, switch connectors, can solve the problem of high raw material costs and copper content in alloys high, weak market competitiveness and other issues, to achieve the effect of excellent cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

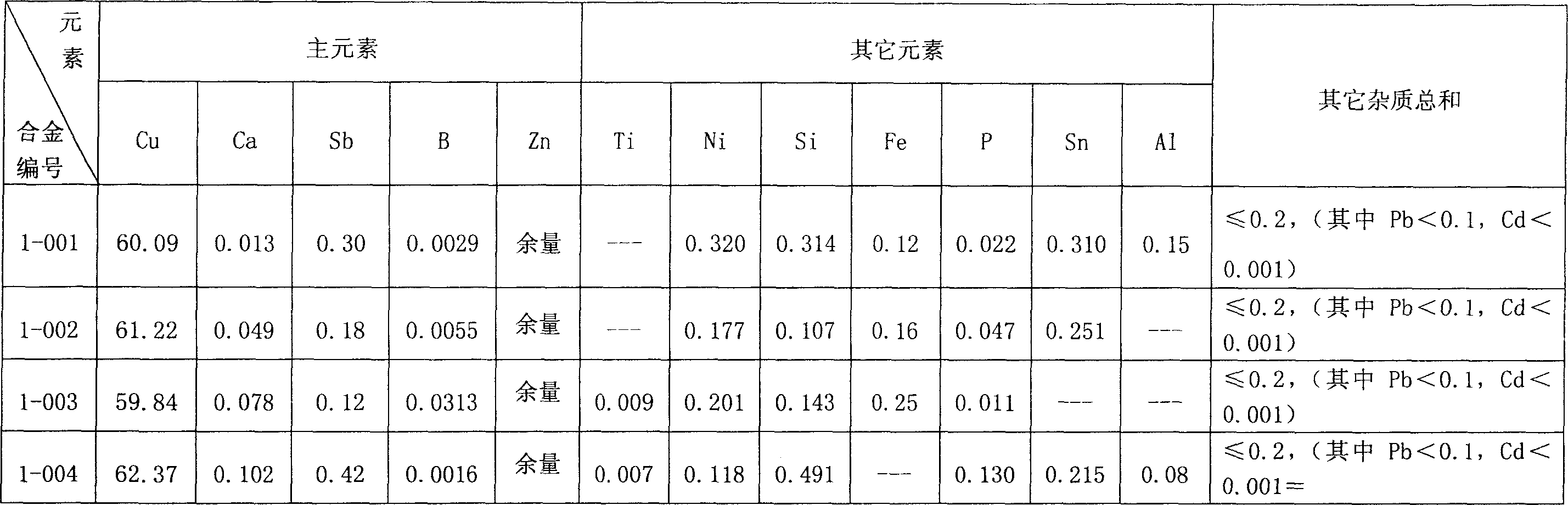

[0121] Table 11: Example of the composition of one of the inventions of the lead-free, easy-cutting, corrosion-resistant, low-boron-calcium brass alloy of the present invention: (wt%)

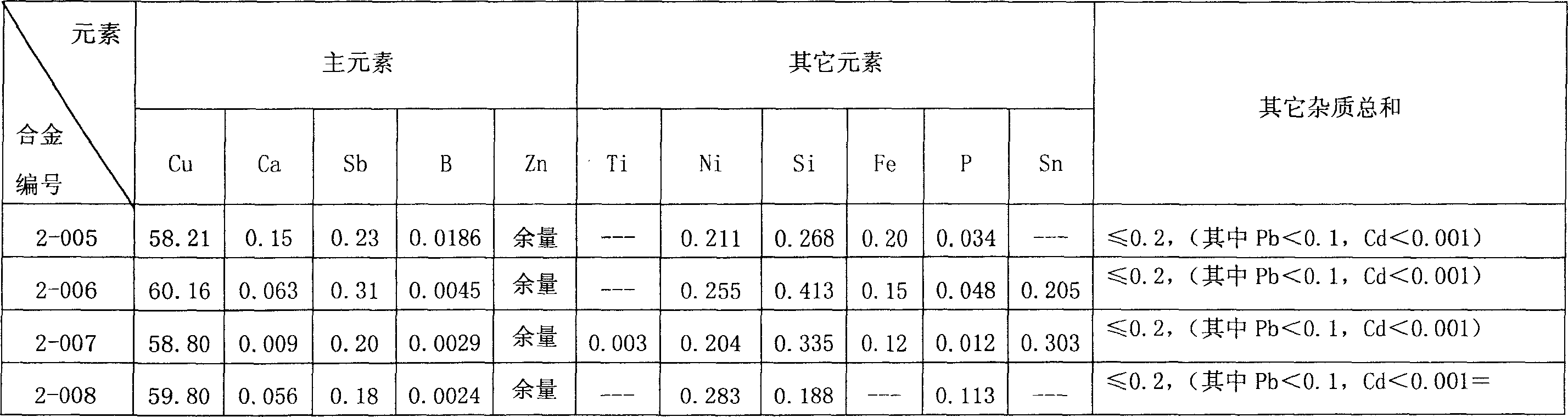

[0122] Table 12: Example of the composition of the second invention of the lead-free, easy-cutting, corrosion-resistant, low-boron-calcium brass alloy of the present invention: (wt%)

[0123] Table 13: Example composition of the third invention of the lead-free, easy-cutting, corrosion-resistant, low-boron-calcium brass alloy of the present invention: (wt%)

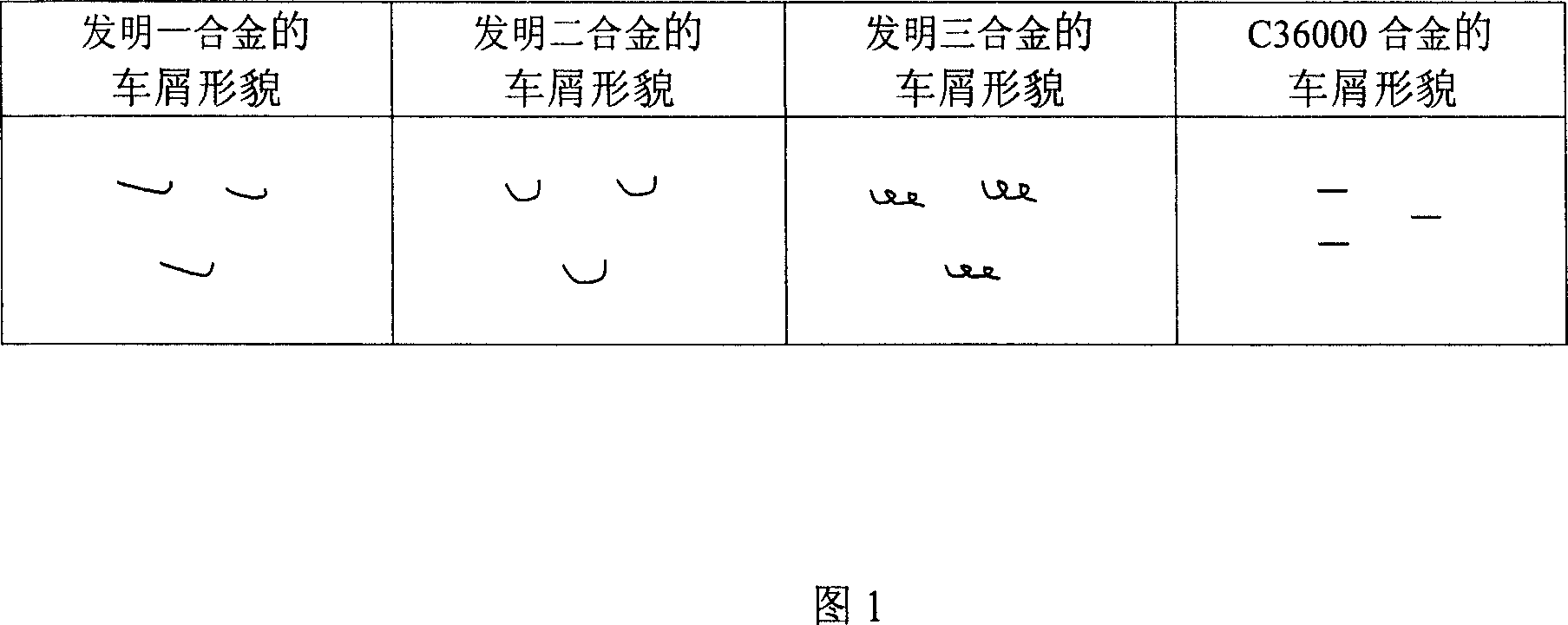

[0124] Table 16 Comparison of machining comprehensive cutting performance of the invention alloy and the comparison alloy

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com