Image measuring method and system of sulfite oxidizing reaction rate

A technology of oxidation reaction rate and sulfite, which is applied in the direction of chemical reaction of materials for analysis, etc., can solve the problems of inability to measure the change rule of reaction rate, large error of gas-liquid contact area, short contact time, etc. Convenience, low consumption of reactants, and small measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

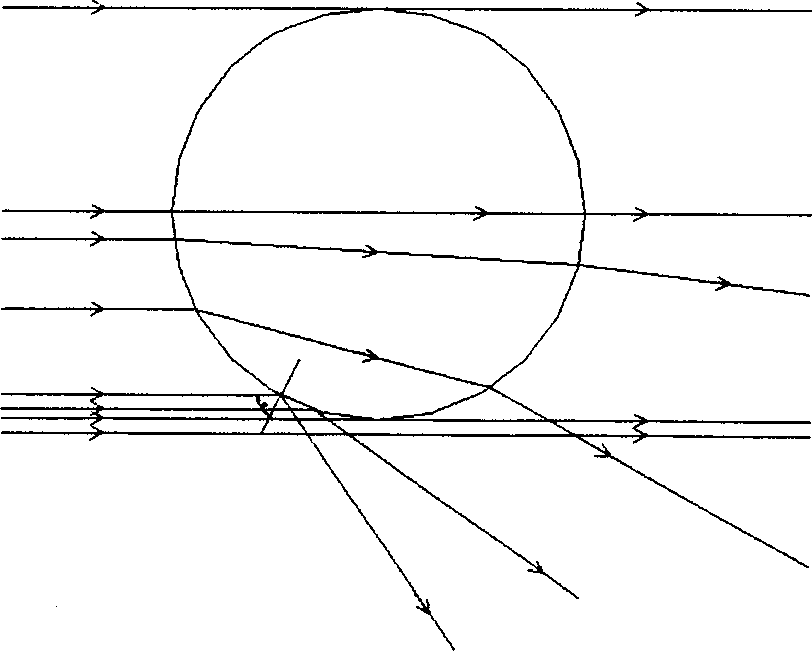

[0027] The oxygen bubbles will be absorbed in the sulfite solution due to the chemical reaction, so the volume of the bubbles will be reduced; when the oxygen bubbles enter the sulfite solution, there are oxygen and sulfite ions near the gas-liquid interface The reaction causes the oxygen bubbles to gradually shrink. Therefore, studying the law of the shrinkage of a single bubble in the solution can find the reaction rate at each moment.

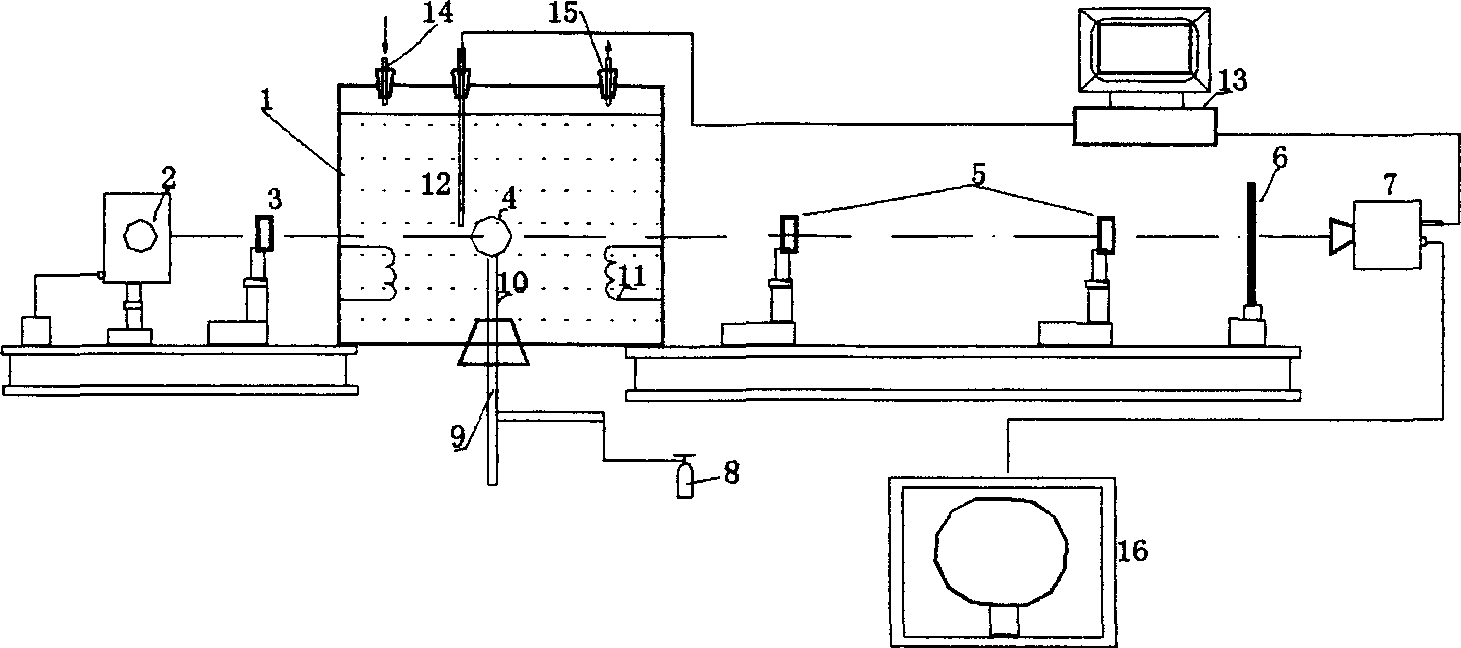

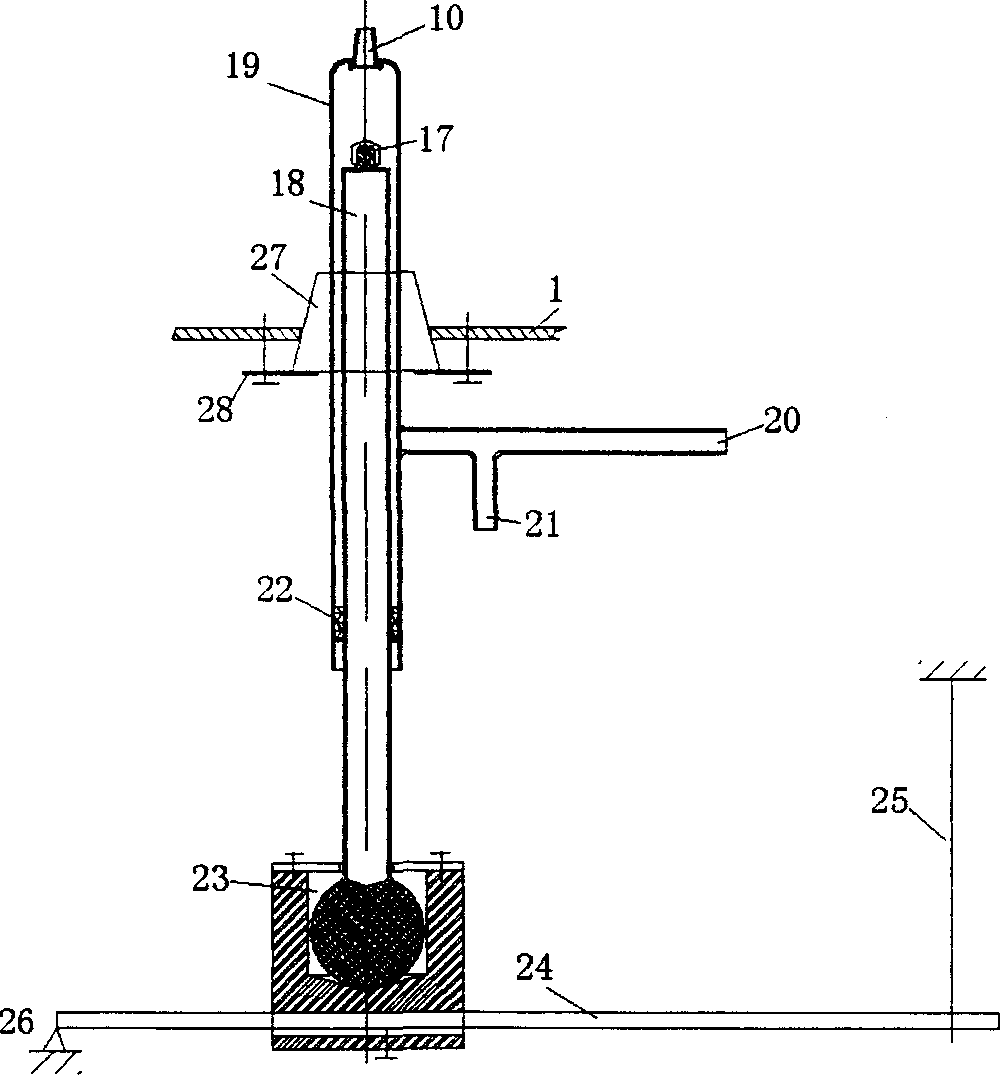

[0028]The present invention is based on the above mechanism and adopts the following technical solutions: the measurement system of the present invention mainly includes a reaction vessel 1 containing a sulfite solution, a single oxygen bubble generation and isolation system 9, a light source 2, a light-shielding hole 3, and a convex lens 5. , The optical path imaging system composed of the image screen 6, the temperature signal acquisition system, the camera 7, and the computer 13 which is connected with the camera and the temperature signal ac...

specific Embodiment

[0054] Specific steps are as follows:

[0055] (1) Inject a certain concentration of sodium sulfite solution into the container and protect it with nitrogen;

[0056] (2) Take a sample of the solution and store it in a sampling bottle;

[0057] (3). The temperature is controlled to the specified value, the impurity gas in the gas injection system is driven out with pure oxygen, and the bubbles are prepared;

[0058] (4). Use the oxygen bubble generation and isolation system to generate an isolated oxygen bubble;

[0059] (5). Debug the optical path imaging system to make the background light enter from behind the bubble;

[0060] (6). Take the first picture of the bubble and start timing at the same time;

[0061] (7). Take a picture at regular intervals and record the time at the same time;

[0062] (8). When the bubble volume decreases to a certain extent, the measurement at that temperature is ended.

[0063] (9). Transfer photos from the memory stick of the camera to the compu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com