Coal gangue haydite and its prepn process

A technology of coal gangue ceramsite and coal gangue powder, applied in ceramic products, other household appliances, sustainable waste treatment and other directions, can solve problems such as endangering human health, destroying ecological balance, destroying crops and trees, etc., and achieving good sound insulation effect , the effect of low thermal conductivity and broad resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

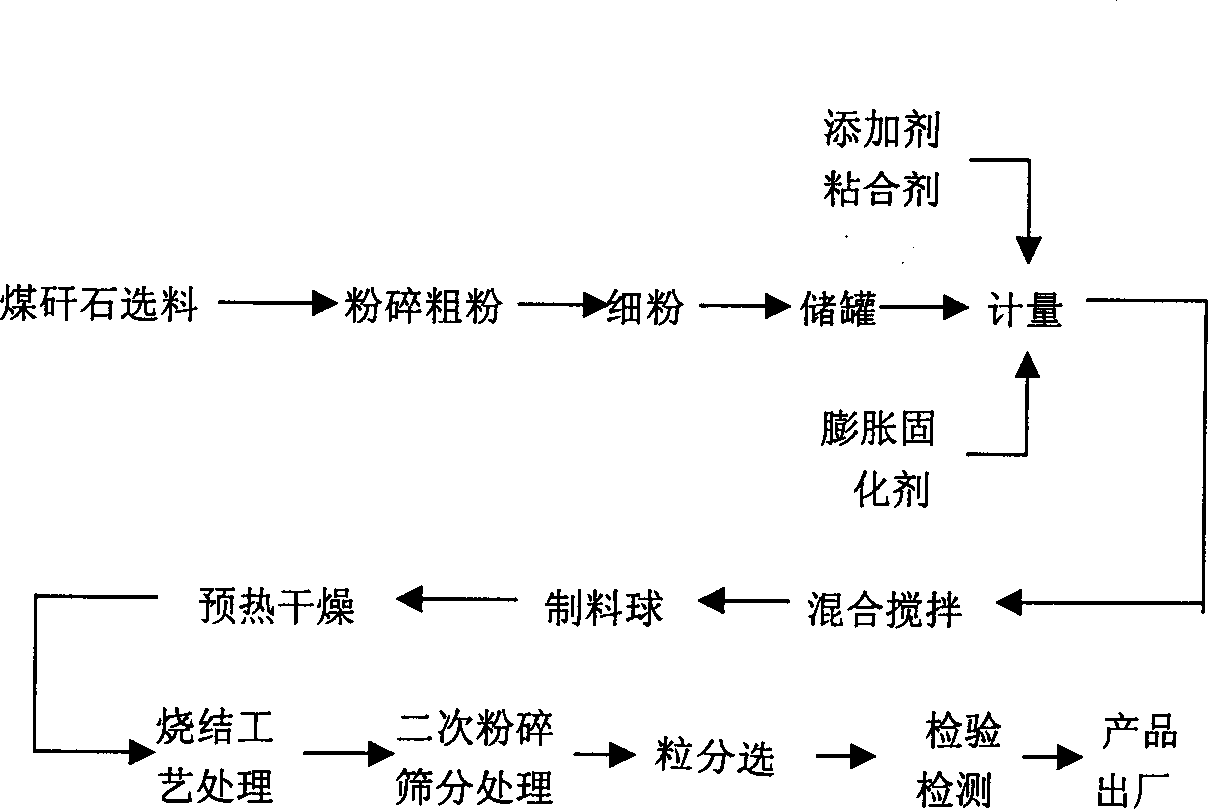

[0023] Embodiment 1: Preparation of gangue ceramsite

[0024] The specific steps for preparing coal gangue ceramsite are as follows: figure 1 Shown: 1. Mineral dressing: remove impurities in coal gangue, crush large pieces of coal gangue with a hand hammer, pick out coal gangue with a diameter of ≤10mm and put it into a crusher for crushing, and then pass through Raymond mill air separation to process into 400 purpose coal gangue powder, then use (weight percentage) clay 35%, shale 65% to form adhesive; 3. Put the above-mentioned mixture into the spiral mixer and stir evenly; 4. Ball making: transfer the above-mentioned mixture to the disc-type ball making machine through the belt, and inject 3% of the Water, the material will naturally form a spherical shape with the inertia of the rotation of the disc, and roll through the ball forming area and the ball discharging area to form a Φ10mm material ball, and the prepared material ball will pass through the elevator to the mater...

Embodiment 2

[0025] Embodiment 2: the specific steps of preparing gangue ceramsite are as figure 1 Shown: 1. Mineral processing: remove impurities in coal gangue, crush large pieces of coal gangue with a hand hammer, pick out coal gangue with a diameter of ≤10mm and put it into a crusher for crushing, and process it into 250 Purpose coal gangue powder; then use (weight percentage) clay 40%, shale 60% to form adhesive; The mixture of additives and 10% fly ash expansion and curing agent is made into a mixture; 3. Put the above-mentioned mixture into a spiral mixer and stir evenly; 4. Ball making: transfer the uniformly stirred mixture to a disc-type ball making machine through a belt, Inject 5% water in the form of a spray, and the material will naturally form a spherical shape with the inertia of the disk, and roll through the ball forming area and the ball discharging area to form a material ball with a diameter of 15mm. The prepared material ball will pass through the elevator to the inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com