Polyamide resin compsns.

A technology of polyamide resin and composition, which is applied in the field of polyamide resin composition and its molded products, and can solve the problems of poor compatibility between semi-aromatic polyamide and polybrominated styrene, poor chemical resistance, surface peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

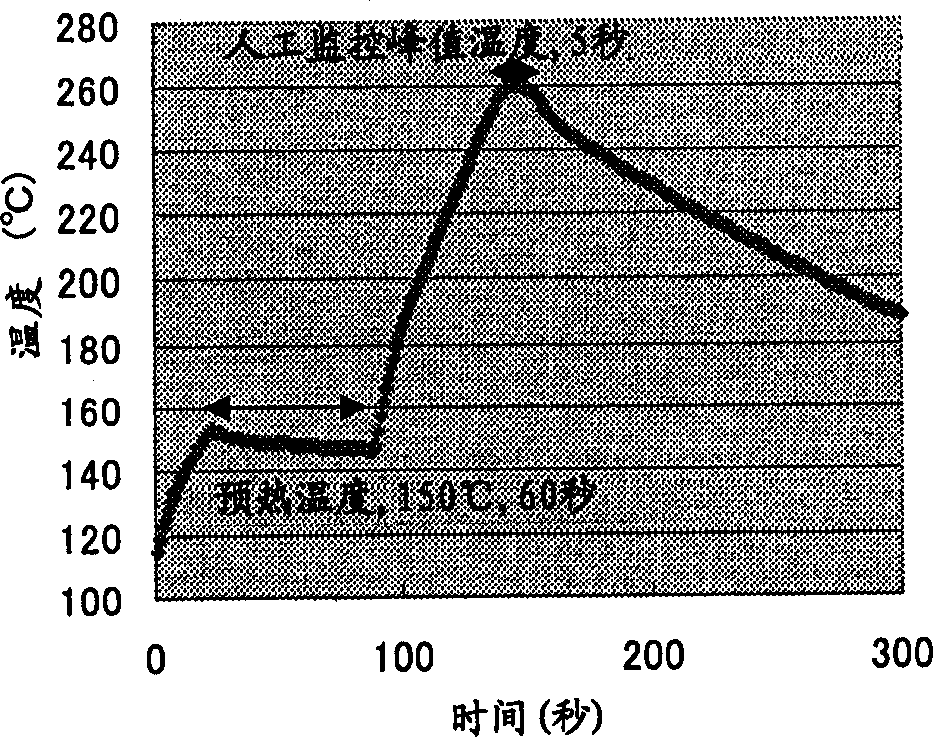

[0057] The above-mentioned polyamide resin was mixed with polybromostyrene (hereinafter referred to as "GMA-PBrS") containing 2.0 mol% glycidyl methacrylate, polybromostyrene (PBS-64 of Great Lakes Chemical, hereinafter referred to as "PBrS"), zinc borate (Borax's Fire Break 415), a mixture of sodium oxide and antimony pentoxide (Nissan Chemical's Sun-EpocNA-1070L), zinc stannate (Nippon Light Metal's FLAMTARD-S), and glass fiber (Nitto Boseki's CS-3J-256S) was premixed in the proportions shown in Table 1 below. The resulting mixture was fed into a twin-screw extruder (TEX44C by Nippon Seikosho), kneaded and extruded in a molten state at a barrel temperature of 320° C., then cooled and cut into pelletized polyamide resin compositions. The pellets were molded in an injection molding machine (barrel temperature 330°C, molding temperature 150°C), and the resulting molded articles were examined as described above. The test results are shown in Table 1. Comparative example 1-2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com